The DTF process, or Direct to Film printing, is revolutionizing the garment printing industry with its unique and innovative approach to creating custom designs. This cutting-edge technique allows businesses to achieve vibrant, high-quality prints on a wide range of fabrics, catering to the growing demand for personalized apparel. By exploring the various DTF printing steps, from initial design through to the finished product, garment decorators can appreciate how this method stands out against traditional printing processes. Among the significant benefits of DTF printing are its versatility, cost-effectiveness, and ability to produce detailed images that enhance the appeal of custom apparel. As more companies recognize these advantages, understanding the nuances of the DTF process is becoming increasingly important for staying competitive in the custom garment market.

The Direct to Film method, often referred to as DTF printing, is gaining traction among apparel decorators and fashion enthusiasts alike due to its impressive functionality and quality output. This garment printing process not only simplifies the transition from digital design to physical fabric but also ensures superior durability and vibrancy in printed designs. With a specific focus on detailed print methods and the crafting of unique apparel, the benefits of DTF printing are clearly evident. As a game changer in the custom clothing arena, it offers unmatched flexibility for enthusiasts aiming to express their styles through unique pieces. By delving deeper into this innovative technology, businesses can capitalize on the evolving trends of personalized fashion.

The Basics of DTF Printing: An Overview

Direct to Film (DTF) printing represents a groundbreaking method in the realm of custom apparel decoration. This technique relies on transferring designs from a specially coated film onto garment fabrics, ensuring vibrant and durable results. The versatility of DTF allows it to cater to an extensive range of fabrics, including cotton and polyester. By utilizing a process that combines advanced printing technology and eco-friendly inks, DTF stands out as a preferred choice for designers and garment decorators alike.

What sets DTF printing apart is its accessibility for small businesses and individual creators. Unlike traditional methods, which often require heavy machinery and extensive setups, DTF allows for smaller production runs without prohibitive costs. This factor is particularly advantageous for those looking to create custom apparel, as it opens doors to personalized fashion without the need for large investments upfront.

Understanding the DTF Process Steps

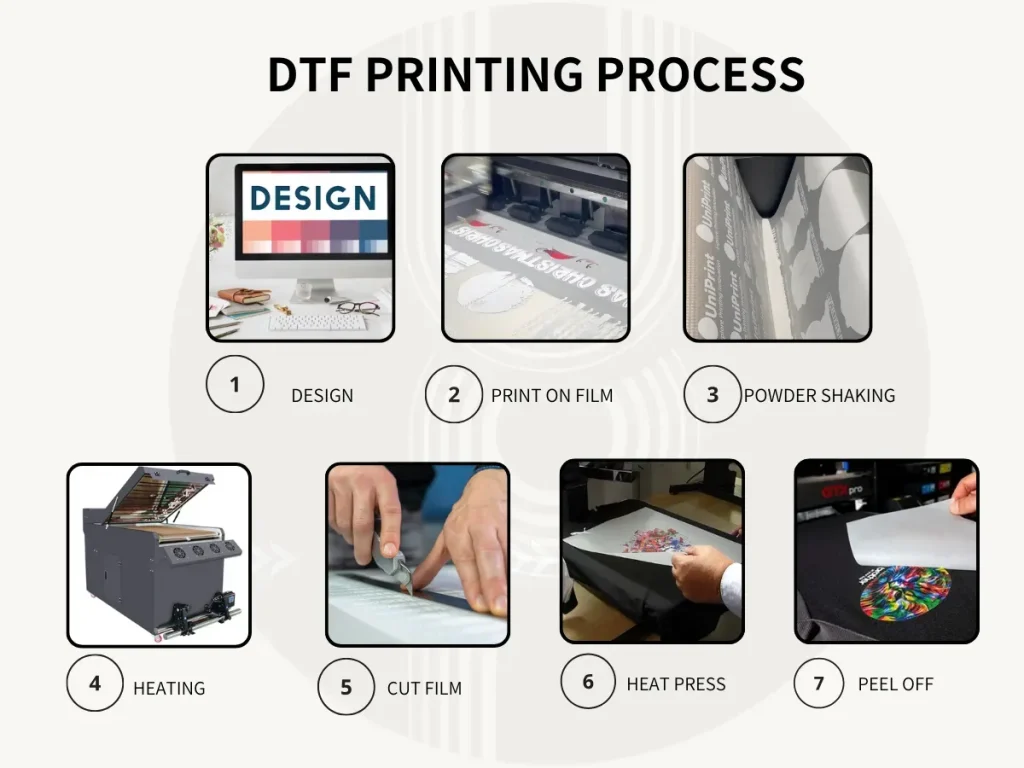

The DTF process is characterized by several crucial steps that ensure successful design transfer and garment decoration. Initially, the process begins with design creation, where graphic designers utilize tools like Adobe Illustrator to craft eye-catching visuals that meet the desired specifications. This careful preparation sets the stage for a high-quality print that reflects the intended style and brand message.

Following design creation, the subsequent steps include printing on the film, applying an adhesive, and transferring the design onto the fabric. Each phase requires meticulous attention to detail, particularly during the curing stage, which solidifies the design’s durability. This series of processes showcases the technical nature of DTF printing, emphasizing its efficiency in producing professional-grade custom apparel.

Advantages of DTF Printing Over Traditional Methods

The benefits of DTF printing are manifold, leading to its increased adoption over more traditional printing methods like screen printing. One of the primary advantages is its versatility. DTF technology allows for high-quality prints on a wide array of fabric types, colors, and textures, which can be challenging for other methods. This flexibility not only caters to diverse consumer preferences but also enables designers to experiment with various styles and finishes.

Moreover, DTF printing delivers exceptional quality output, characterized by vibrant colors and intricate detail. This quality makes it perfect for everything from promotional apparel to personalized clothing items. Additionally, the cost-effectiveness of DTF is notable; it eliminates the need for extensive setup costs and allows for smaller production runs, making it an ideal choice for small businesses aiming to create unique products without significant financial investment.

Recent Innovations in DTF Technology

Technology in the DTF printing arena continues to evolve rapidly, paving the way for exciting new possibilities in garment decoration. Recent advancements focus primarily on improving printer speed and ink formulations, enhancing both the efficiency of the production process and the quality of the final prints. Modern DTF printers are designed to achieve faster turnaround times, accommodating the increasing consumer demand for rapid production without sacrificing print quality.

Additionally, innovations in ink technology have led to the development of more environmentally friendly options that do not compromise the vibrant appearance of the prints. These advancements not only appeal to eco-conscious consumers but also position DTF printing as a forward-thinking choice in the sustainable fashion movement, making it more relevant than ever in today’s marketplace.

Key Trends Influencing the DTF Printing Market

As the appetite for personalized clothing continues to surge, the DTF printing market is on the brink of significant expansion. Consumers are increasingly seeking out custom apparel that reflects their unique identities and interests. This growing trend compels businesses to embrace DTF technology due to its adaptability and cost advantages, tailored for small-scale production.

Moreover, the rise of online platforms for custom clothing has transformed how DTF printing is utilized, empowering consumers to create their designs and directly engage with their apparel choices. Companies that leverage DTF technology can cater to this burgeoning market segment more effectively, ensuring they meet the evolving expectations of today’s fashion-forward populace.

Looking Ahead: The Future of DTF Printing

In conclusion, the future of DTF printing appears promising as its advantages and efficiency gain wider recognition across the apparel industry. As advancements continue to unfold in technology and consumer attitudes, businesses integrating DTF processes into their operations can maintain a competitive edge in the ever-evolving fashion landscape. The ability to transition seamlessly from design to finished product showcases the potential DTF holds for both creativity and profitability.

Furthermore, as industries increasingly value sustainability and customizability, DTF printing positions itself as a critical process in garment production. Companies that stay informed about the latest trends and technologies associated with DTF printing can harness these insights to optimize their offerings, ultimately aligning their products with consumer demands for distinctive and environmentally friendly apparel.

Frequently Asked Questions

What is the Direct to Film (DTF) printing process?

Direct to Film (DTF) printing is an innovative garment printing process that transfers designs via a film coated with adhesives, allowing for vibrant and durable prints on various fabrics like cotton and polyester. This method stands out in the custom apparel industry for its ability to deliver high-quality results with ease.

What are the key steps involved in the DTF printing process?

The DTF printing process consists of crucial steps: 1) design creation using graphic design software; 2) printing on a specially coated film; 3) applying a powdered adhesive to the wet ink; 4) transferring the film to the fabric with a heat press; and 5) curing to ensure durability and adherence of the design.

What are the benefits of using DTF printing for custom apparel?

The benefits of DTF printing include versatility, as it works on various fabrics and colors; quality output with vibrant and detailed images; and cost-effectiveness, allowing for small batch production without high setup costs, making it ideal for businesses and individuals desiring custom apparel.

Can DTF printing be used for all types of fabrics?

Yes, DTF printing is versatile and can be applied to a wide range of fabrics, including cotton, polyester, and fabric blends, making it suitable for a variety of custom apparel options without the limitations of traditional methods.

How does the DTF process ensure the durability of prints?

The DTF process ensures durability through a two-step curing process. After the design is transferred to the garment, additional heat curing is applied, which strengthens the adhesive bond between the print and fabric, enhancing resistance to washing and wear.

What recent advancements are shaping the future of DTF printing?

Recent advancements in DTF printing technology include faster printer speeds and improved ink formulations, enhancing efficiency and quality. These innovations cater to the growing demand for personalized clothing, allowing businesses to produce high-quality custom apparel quickly.

| Key Points | Details |

|---|---|

| What is DTF Printing? | DTF printing is a method that transfers designs onto fabrics using a film treated with adhesives, ideal for various materials. |

| The DTF Process Steps | 1. Design Creation 2. Printing on Film 3. Applying Adhesive 4. Transfer to Fabric 5. Curing |

| Benefits of DTF Printing | – Versatility with various fabrics – High-quality outputs – Cost-effective for small runs |

| Recent Developments | Advancements in printer speed and ink formulations enhancing efficiency and quality. |

| Industry Trends | Growing demand for personalized clothing driving adoption of DTF technology. |

Summary

The DTF process, or Direct to Film printing process, is revolutionizing the garment printing industry by allowing businesses to create vibrant and durable custom designs with ease. From the initial design creation through to the final curing step, each component of the DTF process ensures a high-quality product that can accommodate a variety of fabrics and colors. Its versatility and cost-effectiveness make it an ideal solution for both small businesses and large manufacturers looking to cater to the increasing demand for personalized apparel. As advances in technology continue to arise, staying informed about the latest trends and innovations in DTF will be pivotal for any apparel business aiming to thrive in a competitive market.