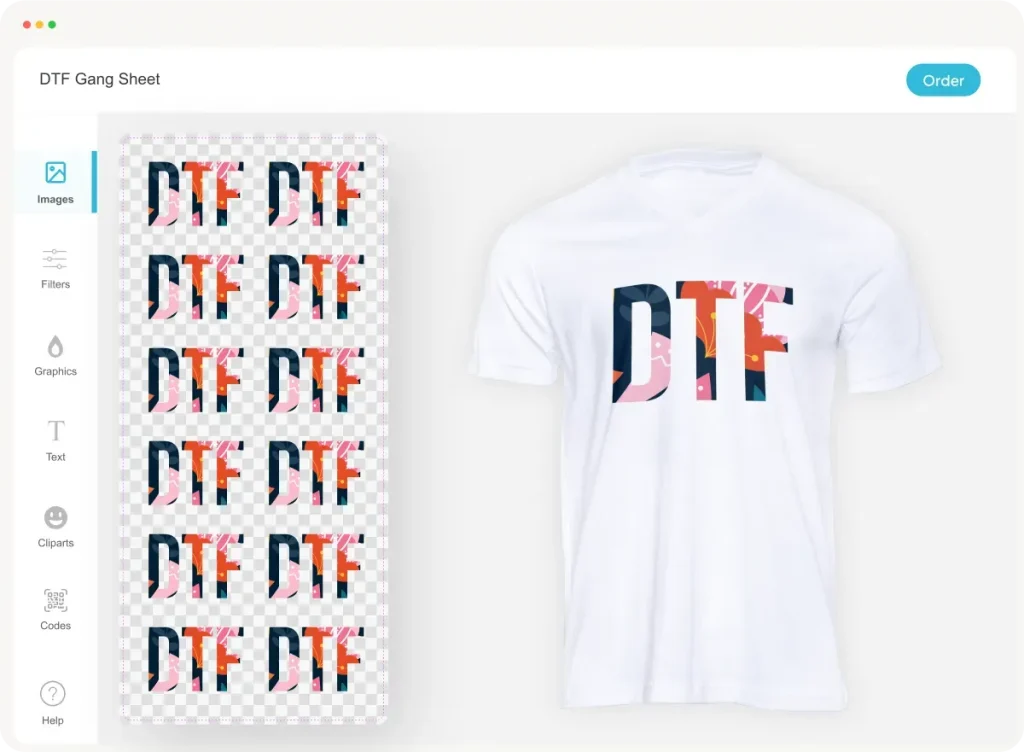

Embarking on your DTF (Direct to Film) printing journey? Look no further than the DTF Gangsheet Builder, a powerful tool designed to streamline your design process and enhance the quality of your prints. This innovative solution significantly optimizes DTF printing techniques, allowing you to maximize your resources and minimize waste. By mastering gangsheet design tips, you can efficiently layout multiple designs on a single sheet, making your printing process not only cost-effective but also creatively fulfilling. In this guide, we will delve into essential strategies for leveraging DTF layout optimization to achieve stunning DTF printing quality.

When it comes to mastering the intricacies of DTF printing, the use of a gangsheet builder proves invaluable. This versatile tool allows for the strategic arrangement of designs, ensuring that you get the most out of every film sheet. With numerous techniques available for this printing method, effective layout management is crucial in ensuring the vibrancy and durability of transfers. By applying thoughtful design strategies, you can not only enhance the efficiency of your processes but also achieve remarkable printing results that stand out in today’s market. In the following sections, we’ll explore various strategies and insights to elevate your DTF design work.

Understanding DTF Printing Techniques

DTF printing, or Direct to Film printing, is a cutting-edge method that revolutionizes how designs are transferred onto fabrics. This process involves printing designs onto a specially coated film before applying heat to transfer those images onto the material. The quality ofprints produced through DTF technology stands out due to the rich color vibrancy and durability against wear and tear, making it a favored choice among businesses and artists alike. By mastering DTF techniques, designers can ensure that their creations not only look great but also withstand the test of time.

When utilizing DTF printing techniques, it’s crucial to pay attention to the type of transfer film used, as various options can affect the final output quality. Additionally, understanding the intricacies of the ink formulations, including pigment and adhesive layering, can contribute to achieving optimal results. Designers should also keep updated with the latest innovations in DTF technology, as advancements are constantly being made to enhance efficiency and product quality, thus allowing for greater creativity without compromising on standards.

Tips for Effective Gangsheet Design

Designing with a DTF gangsheet builder can significantly reduce production costs and increase efficiency. One essential tip is to arrange your graphics on the gangsheet efficiently. Aim to position similar designs close to each other to minimize wasted material and make the most of the printing surface. This strategic layout helps in optimizing the prints and ensures you maximize every inch of film available.

Furthermore, grouping designs based on color harmony or thematic elements can streamline your printing process. This not only saves time during setup but also produces prints that share a cohesive look, enhancing the overall aesthetic of your collection. Leveraging the gangsheet builder effectively allows you to create a visually appealing and economically sound product, which is essential in competitive markets.

Ensuring DTF Printing Quality

To achieve high-quality DTF prints, it is vital to focus on key elements such as resolution, color accuracy, and film handling. Always use images with a resolution of at least 300 DPI to ensure that the fine details of your design are preserved during the transfer process. Low-resolution images can result in pixelation and blurred lines, undermining the professional quality of the final product.

Color accuracy is another critical factor in DTF printing. Utilizing appropriate color profiles specific to DTF technology ensures that colors are rendered accurately on the fabric. Regularly conducting print tests prior to major runs can help in refining color settings and achieving the desired vibrancy in your designs, ultimately enhancing customer satisfaction.

DTF Layout Optimization Strategies

Optimizing your DTF layouts is an essential skill that can significantly enhance your printing results. Adjusting the design placement to reduce blank spaces and align graphics strategically not only conserves film but also creates an overall professional appearance. Using design software accustomed to gangsheet layouts helps streamline this process and provides tools for achieving the best fit for your designs.

In addition, considering the order in which the designs will be printed can help manage workflow effectively. By prioritizing certain designs based on demand or complexity, you can optimize production time and resources. These strategies not only improve operational efficiency but also increase the potential profitability of your printing projects.

Utilizing Transparency in DTF Designs

Transparency is a powerful design tool when creating graphics for DTF printing. By effectively using transparent elements, designers can add depth and sophistication to their work. Whether it’s soft gradients in the background or faded edges around a silhouette, incorporating transparency can lead to visually striking results that elevate the overall design.

However, it is essential to test how these transparent elements interact with the fabric. Certain materials may absorb inks differently, which can affect the final appearance. Conduct thorough testing on scrap fabric pieces to ensure colors and transparencies render as expected before committing to a full run. This practice minimizes potential print errors and maximizes the aesthetic appeal of your designs.

Current Trends in DTF Printing

Staying updated with trends in DTF printing is crucial for any designer looking to make a mark in the industry. As consumer preferences evolve, so do the styles and techniques that resonate with audiences. Keeping an eye on popular themes and color palettes can inspire innovative designs and enhance marketability, helping your products stand out in a crowded marketplace.

Additionally, following influential designers and exploring online platforms can provide insights into emerging trends. Participating in online forums and attending trade shows dedicated to printing technology can further enrich your knowledge and offer opportunities for networking. Embracing current trends while maintaining your unique design voice is key to effective branding and successful sales.

Frequently Asked Questions

What is a DTF Gangsheet Builder and why is it important for DTF printing?

A DTF Gangsheet Builder is a tool that allows you to arrange multiple designs onto a single sheet of DTF film, optimizing the layout for printing. It’s essential for improving efficiency, reducing material waste, and enhancing overall print quality in DTF printing projects.

How can I optimize my DTF layout using a gangsheet builder?

To optimize your DTF layout with a gangsheet builder, use design software like CAD or specialized tools to arrange your designs closely together, minimizing unused film space. Aim for simplicity in your designs and strategically position elements to maximize print area and prevent excess material wastage.

What are key tips for achieving high DTF printing quality?

To ensure high DTF printing quality, use high-resolution images (at least 300 DPI), manage color profiles accurately, and perform test prints to assess design efficacy. Implementing these practices will help achieve vibrant colors and crisp details in your final prints.

What design resolution should I use for DTF printing projects?

For optimal results in DTF printing projects, ensure all images used are at least 300 DPI. This resolution maintains detail during the transfer process and contributes to achieving the best possible print quality.

How can grouping similar designs improve my DTF printing efficiency?

Grouping similar designs in your gangsheet builder can streamline the printing process by reducing setup times and ensuring color consistency across the final products. This practice saves time and resources, leading to a more efficient workflow.

What recent advancements in DTF technology should I be aware of for better designs?

Recent advancements in DTF technology include faster printing speeds and improved ink formulations that enhance durability and color retention. Staying updated on these developments can help you utilize the latest innovations to create higher quality DTF prints.

| Tip | Description |

|---|---|

| Understanding DTF Technology | Get familiar with how DTF printing works, using a gangsheet builder for fabric printing efficiency. |

| Optimize Layouts | Use software like CAD to arrange designs effectively, ensuring minimal material waste. |

| Color Management | Employ proper color profiles and test prints to guarantee accurate colors on fabric. |

| Design Size and Resolution | Maintain high-resolution images (minimum 300 DPI) for better print quality. |

| Test Before Full Runs | Conduct test prints to avoid errors and adjust designs without wasting materials. |

| Use Transparency Wisely | Incorporate transparency to create appealing effects in designs and layouts. |

| Grouping Similar Designs | Group designs by color or theme for efficiency and uniformity during printing. |

| Stay Updated with Trends | Keep an eye on design trends to improve the appeal of your projects. |

| Recent Developments in DTF Technology | Advancements in technology have improved print quality and operational costs. |

| Useful Resources | Blogs, forums, and YouTube tutorials can enhance DTF printing knowledge. |

Summary

DTF Gangsheet Builder is a pivotal tool for any designer venturing into DTF printing. By mastering the tips and techniques detailed in this guide, including layout optimization, effective color management, and keeping abreast of industry advancements, you can significantly enhance both the creative and technical aspects of your design projects. Such strategic approaches not only elevate the quality of your prints but also streamline your production process, making your DTF printing endeavors more cost-effective and artistically rewarding.