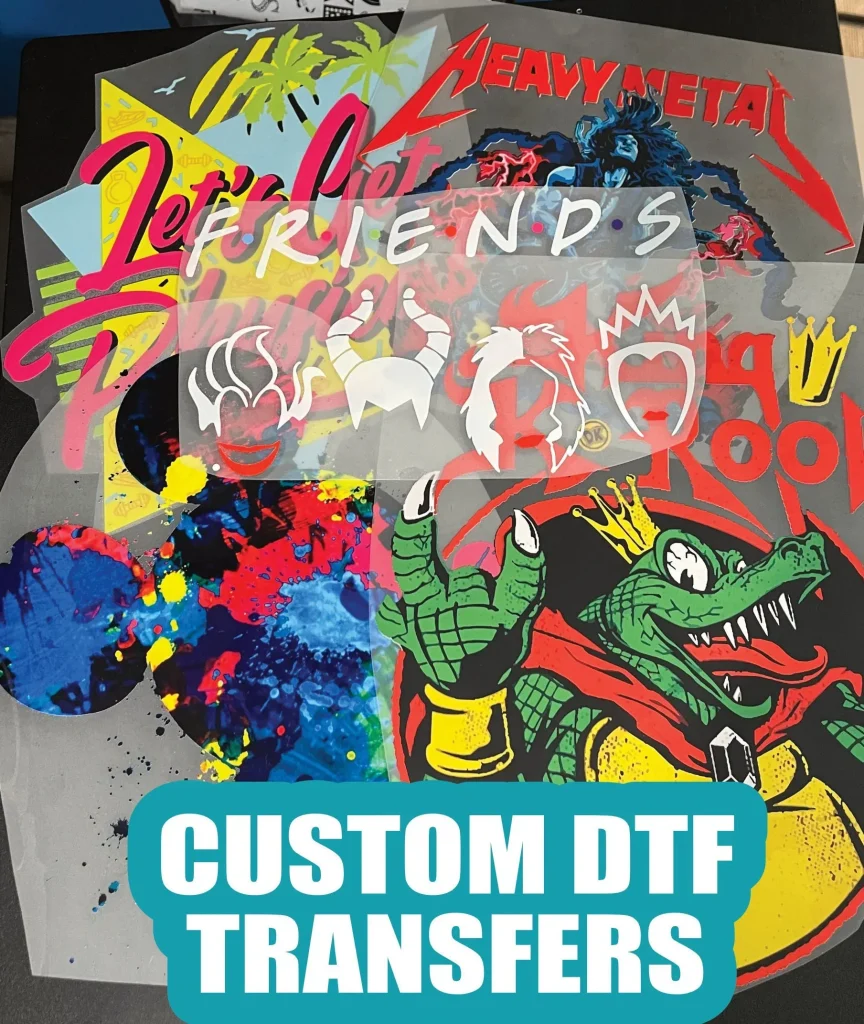

DTF Transfers, or Direct-to-Film Transfers, have revolutionized the custom apparel printing landscape with their ability to deliver stunning designs across a variety of fabrics. As businesses look for efficient and versatile printing methods, DTF stands out as a compelling alternative to traditional techniques like screen printing and DTG (Direct-to-Garment) printing. With DTF Transfers, high-quality graphics can be easily applied, making them ideal for both intricate designs and larger runs. This paragraph will delve deeper into the pros and cons of DTF Transfers compared to other printing techniques, helping you navigate your options effectively. If you aim to enhance your custom printing services, understanding these innovations is crucial for success in the modern market.

In the realm of custom fabric printing, alternative methods such as Direct-to-Film Transfers have emerged as game-changers, offering distinct advantages over conventional approaches. This technique allows for a seamless transfer of detailed designs onto garments, thus presenting an efficient solution compared to methods like screen printing and direct-to-garment processes. By harnessing the versatility of DTF Transfers, businesses can cater to diverse fabric types without compromising on quality. Understanding these various printing methodologies, from traditional practices to cutting-edge innovations, can provide valuable insights for anyone looking to enhance their apparel offerings. By weighing the benefits and limitations, you can make a more informed choice that aligns with your creative and operational goals.

Advantages of DTF Transfers in Custom Apparel

DTF Transfers have emerged as a frontrunner in the world of custom apparel printing, primarily due to their ability to offer unmatched versatility. Unlike screen printing, which often confines designs to specific fabric types, DTF Transfers can seamlessly print on a wide array of materials including cotton, polyester blends, and even delicate fabrics like silk. This flexibility allows businesses to cater to diverse customer needs, providing options that traditional printing methods may not offer.

Furthermore, the intricate detail that DTF Transfers can achieve sets it apart from other techniques. With the capacity to produce vibrant, multi-colored graphics without the need for multiple screens, DTF becomes the preferred choice for custom projects requiring fine detail and vibrant colors. In short, its ability to adapt and deliver quality prints makes DTF an essential method for any apparel printer.

Streamlining Production with DTF Transfers

One of the most significant attributes of DTF Transfers is the streamlined production process they offer. Traditional screen printing is often bogged down by the necessity of setting up various screens for each color used in a design, which can add time and complexity to job setups. In contrast, DTF allows for quicker turnaround times since it requires only one setup for an entire design, significantly reducing preparation time and associated costs.

This efficiency makes DTF Transfers particularly appealing for smaller businesses or those that engage in smaller production runs. The straightforward printing process not only leads to cost savings but also enables quicker adaptation to changes in customer demands. Thus, businesses can respond swiftly to market trends, making DTF an agile alternative for custom apparel printing.

Comparing DTF and DTG Printing Techniques

When assessing DTF Transfers against DTG Printing, it’s important to recognize the strengths and weaknesses of both techniques. DTG Printing delivers exceptional wash durability, often resulting in softer finishes as the ink bonds directly with the fabric. However, this technique falls short when it comes to versatility—DTG is best suited for 100% cotton fabrics, which may limit options for other types of apparel.

On the other hand, DTF Transfers shine due to their ability to print on a wider variety of fabrics, making them ideal for businesses looking to offer diverse product lines. Companies can easily switch between fabric types without compromising print quality, which is a major advantage in today’s market where customization and variety are paramount.

DTF Transfers vs. Traditional Screen Printing

Despite the longstanding reputation of screen printing as a cost-effective solution for bulk orders, DTF Transfers provide an enticing alternative. The ability to achieve intricate and vibrant designs without needing multiple screens means DTF can tackle custom orders that require a quick turnaround without sacrificing quality. As a result, businesses are increasingly favoring DTF as a method capable of meeting the demand for customized apparel with precision.

Moreover, businesses that traditionally relied on screen printing might currently find themselves at a disadvantage when it comes to smaller order quantities. Screen printing often benefits larger batch runs due to setup costs, while DTF Transfers are designed to handle anything from small runs to complex, detailed graphics easily. This adaptability allows businesses to serve their customers with better flexibility.

Durability in DTF Transfers: What to Expect

One common concern regarding DTF Transfers is the longevity and durability of prints compared to other techniques. While DTF prints adhere well to fabrics, the durability can vary based on materials and application methods. It’s crucial for businesses to conduct tests and possibly seek advice from experts to ensure that the prints maintain their quality over time, especially for garments that will be frequently washed or subjected to heavy use.

Maintaining the quality of DTF prints can also hinge on post-printing care, including proper heat setting and washing instructions. By following best practices, businesses can maximize the lifespan of their prints, ensuring a reliable product that upholds customer satisfaction and brand assurance.

Making the Right Choice: DTF Transfers for Your Business Needs

Deciding between DTF Transfers and other printing techniques ultimately comes down to specific business needs and project requirements. If a company frequently takes on custom orders requiring quick turnaround times and varying fabric types, DTF Transfers emerge as a compelling option. The versatility and efficiency they offer can enhance production capabilities and meet customer demands effectively.

However, it’s equally crucial to weigh the initial investment against the potential return on investment. Evaluating both the long-term benefits and the upfront costs associated with DTF technology can help businesses determine whether it aligns with their strategic goals in the custom apparel market. Understanding the unique capabilities of DTF, DTG, and screen printing can empower businesses to make informed choices that support their growth.

Frequently Asked Questions

What are DTF Transfers and how do they differ from DTG printing?

DTF Transfers, or Direct-to-Film Transfers, involve printing designs onto a specialized film which is then transferred onto fabric using heat. Unlike DTG (Direct-to-Garment) printing that directly applies ink onto the garment, DTF offers greater versatility across different fabric types and is particularly adept at rendering intricate designs with high clarity.

Can DTF Transfers be used on various fabric types?

Yes, one of the key advantages of DTF Transfers is their versatility. DTF can be applied seamlessly to a wide range of materials, including cotton, polyester blends, and synthetic fabrics, without the need for pre-treatment, making it an excellent choice for custom apparel printing.

What are the main benefits of using DTF Transfers for custom apparel printing?

The main benefits of DTF Transfers include their versatility across various fabrics, the ability to produce intricate and multi-colored designs with clarity, and a streamlined printing process that reduces setup time and costs compared to traditional screen printing.

Are there any downsides to using DTF Transfers compared to screen printing?

While DTF Transfers offer many benefits, there are some downsides. DTF requires specialized equipment, which can be a significant initial investment. Additionally, there are concerns about the long-term durability of prints, which can vary based on application techniques and fabric quality.

How do DTF Transfers compare to screen printing in terms of production efficiency?

DTF Transfers generally provide greater production efficiency than screen printing, as they do not require multiple screens for different colors. This streamlined process reduces setup time and costs, making DTF a preferred choice for custom orders and smaller production runs.

What equipment is necessary for DTF Transfers and is it worth the investment for small businesses?

DTF Transfers require specialized printers and materials, which can represent a substantial investment for small businesses. However, the long-term benefits, such as higher print quality and versatility across multiple fabrics, may justify the upfront costs depending on your printing needs and business goals.

| Key Printing Techniques | DTF Transfers | Other Techniques | |

|---|---|---|---|

| Versatility | High adaptability to various fabrics without pre-treatment. | ||

| Intricate Designs | Excellent detail retention for complex designs. | ||

| Streamlined Process | Fewer setup requirements compared to screen printing. | ||

| Specialized Equipment | Requires specific printers and materials, which can be costly. | ||

| Durability Concerns | Print lifespan may vary based on application and fabric quality. | ||

| Comparison with DTG Printing | DTG excels in wash durability while DTF provides better design flexibility. | ||

| Comparison with Screen Printing | Screen printing is cost-effective for bulk but lacks the vibrancy of DTF. | ||

Summary

DTF Transfers are a remarkable choice for those in the custom apparel printing industry, combining versatility, the ability to execute intricate designs, and a more streamlined production process. Their capability to print on various fabric types without the need for pre-treatment stands in contrast to other methods, making them an optimal solution for businesses focusing on customization. While the requirement for specialized equipment and potential durability issues may deter some, the long-term benefits often outweigh these drawbacks. This means that DTF Transfers not only cater to complex design needs but also support businesses in expanding their product offerings effectively.