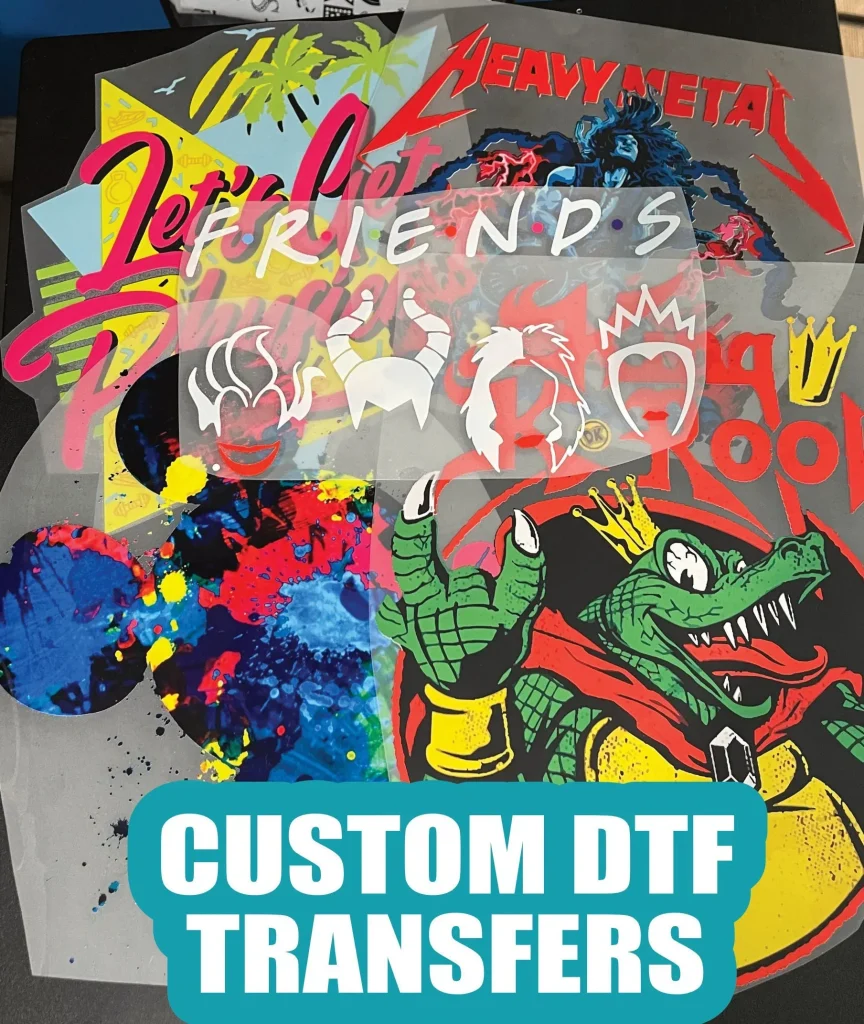

DTF transfers, or Direct to Film transfers, have emerged as a revolutionary method in the world of custom garment printing. Despite their increasing popularity, numerous myths and misconceptions about DTF printing often cause confusion and hesitation for potential users. Many believe that DTF transfer quality is subpar compared to traditional methods, or that it carries a significant environmental impact. In this article, we will debunk these DTF printing myths and explore the remarkable advantages of adopting this technology, from its versatility in fabric compatibility to its efficiency in production. By shedding light on the realities of DTF transfers, we aim to empower creators to fully appreciate the benefits that come with this innovative printing technique.

When discussing DTF transfers, one might also encounter terms like direct-to-film printing and film transfer technology, both of which refer to the same groundbreaking approach in textile customization. This form of printing enables detailed and vibrant designs to be applied to various fabric types effectively. While some skeptics may hold onto common myths about the DTF printing process, such as its complexity or quality concerns, the reality showcases its many advantages, including ease of use and high durability. By understanding these alternative phrasing and concepts associated with DTF printing, businesses can confidently navigate the garment printing landscape. Embracing this knowledge is crucial for anyone looking to leverage the efficiencies and creative possibilities offered by DTF technologies.

Common Misconceptions About DTF Printing

One of the most pervasive misconceptions about DTF printing is that it is only suitable for specialized fabrics. Many newcomers to garment printing mistakenly believe that this technique can only be applied to a narrow range of materials. In reality, DTF transfers are incredibly versatile. They can be applied to cotton, polyester, blends, and even more exotic fabrics. This broad compatibility allows businesses to diversify their product ranges without being constrained by fabric limitations.

Additionally, the notion that DTF prints are subpar when stacked against other printing methods like screen printing or DTG is also misguided. With the right techniques and care, DTF printing can achieve vibrant colors and long-lasting durability. The method has evolved to deliver exceptional print quality, thereby debunking the idea that it is an inferior option in the world of textile printing.

DTF Transfer Quality and Durability

Another myth is that DTF transfer quality is lacking compared to traditional methods. This stems from a misunderstanding of the technology’s capabilities. DTF printing utilizes specialized inks that produce high color vibrancy and detailed imagery on fabric. When executed correctly, DTF transfers can withstand washing and wear, rivaling the durability of established techniques.

Moreover, quality assurance can be maintained by following proper curing methods, which solidifies the ink on the fabric and enhances its longevity. This focus on transfer quality is essential for businesses aiming to provide their customers with not just beautiful designs but also products that stand the test of time.

Understanding the DTF Printing Process

A common misunderstanding about DTF printing is that it is an intricate and expensive process. While the initial setup does involve purchasing a DTF printer and heat press, the overall costs are often lower compared to traditional screen printing. For small businesses looking to enter the custom printing market, DTF presents an accessible starting point with manageable expenses.

Moreover, the DTF printing process has seen significant simplifications in recent years. Today’s technology allows new users to master the technique quickly, minimizing the need for extensive training or complicated procedures. This ease of use helps businesses efficiently produce high-quality prints from the get-go.

Easy Application Techniques in DTF Printing

There’s a misconception that applying DTF transfers is a difficult task. In reality, when following the recommended guidelines for heat and pressure settings, the application process is straightforward. With a little practice, users can achieve professional quality results with minimal hassle. This accessible method is one of the main reasons businesses are drawn to DTF transfers.

Additionally, DTF transfers reduce the likelihood of application errors compared to other printing methods. The technology’s user-friendly nature means that once you’ve grasped the basics, it can be easy to replicate successful results, ensuring consistency across batches and contributing to a positive customer experience.

The Role of Pre-Treatment in DTF Printing

Some people wrongly believe that DTF printing eliminates the need for any pre-treatment of fabrics, a step commonly seen in Direct to Garment (DTG) processes. While DTF simplifies many aspects of garment printing, pre-treating can significantly enhance print quality and adhesion. This step is particularly beneficial for certain types of fabric, ensuring a strong bond between the transfer and the material.

Understanding fabric requirements and pre-treatment options can play an essential role in achieving optimal results with DTF printing. Taking the time to enhance the transfer’s adherence can ensure that the final product meets quality expectations and lasts through countless washes.

Environmental Benefits of DTF Printing

There’s a prevailing belief that DTF printing is harmful to the environment, largely due to misconceptions about the materials and processes involved. In truth, many DTF suppliers are shifting towards more eco-friendly practices, including the use of water-based inks that are less damaging than traditional solvent-based alternatives. This contributes to a lower environmental impact while still delivering high-quality prints.

By selecting suppliers who prioritize sustainable practices and using eco-friendly materials, businesses can significantly lessen their ecological footprint while engaging in DTF printing. Deducing the environmental impact associated with garment printing allows companies to make informed decisions that align with their values and resonate with environmentally conscious consumers.

Frequently Asked Questions

What are some common myths about DTF transfers?

Common myths about DTF transfers include the belief that they are only suitable for specialized fabrics, that they offer lower quality than other printing methods, and that they require complicated, expensive equipment. In reality, DTF printing is versatile, provides high-quality results, and has relatively low start-up costs.

Is the quality of DTF transfers inferior to traditional printing methods?

No, DTF transfers can actually match or exceed the quality of traditional printing methods like screen printing and DTG. With proper technique, DTF printing produces vibrant colors and durable designs that withstand wear and washing.

Do DTF transfers require pre-treatment of fabrics for optimal results?

While DTF transfers are less dependent on pre-treatment than DTG printing, applying a pre-treatment can enhance adhesion and improve the overall quality of the print, particularly on certain fabric types.

What environmental impact does DTF printing have compared to other methods?

The environmental impact of DTF printing is not excessive. Many DTF suppliers use water-based inks, which are less harmful than solvent-based inks. Businesses can further minimize their impact by choosing suppliers that prioritize sustainable practices.

Can DTF transfers be applied to any type of fabric?

Yes, DTF transfers are highly versatile and can be applied to various fabric types, including cotton, polyester, and blends. This adaptability makes DTF printing suitable for a wide range of garments.

Is it difficult to apply DTF transfers effectively?

Not at all! If the recommended heat and pressure settings are followed, DTF transfers are relatively easy to apply. With practice, users can achieve consistent, professional-looking results with fewer application mistakes.

| Myth | Fact |

|---|---|

| DTF Printing is Only for Specialized Fabrics | DTF transfers can be used on various materials including cotton, polyester, and blends. |

| DTF Transfers are of Lower Quality Than Other Methods | Properly done DTF printing delivers high color vibrancy and durability. |

| DTF Printing Requires Expensive and Complex Equipment | Entering the DTF market can have lower start-up costs and is easy to learn. |

| DTF Films are Hard to Transfer | With the right techniques, DTF transfers are straightforward and user-friendly. |

| DTF Doesn’t Require Pre-Treatment | Pre-treating fabrics can enhance adhesion and print quality. |

| Environmental Concerns Are Exaggerated | Many DTF suppliers use water-based inks that are less harmful to the environment. |

Summary

DTF transfers are revolutionizing the custom garment printing industry by offering an innovative, versatile alternative for businesses to produce vibrant designs on various fabrics. Despite the numerous myths and misconceptions surrounding DTF transfers, the facts highlight its potential as a high-quality, durable, and cost-effective printing method. Understanding DTF transfers equips businesses to leverage this technology more effectively, ensuring they capitalized on the growing demand for personalized apparel.