In today’s dynamic printing landscape, **DTF transfers**—or Direct-to-Film transfers—are revolutionizing how we approach apparel production. With an increasing emphasis on sustainability, DTF technology emerges as a frontrunner, offering eco-friendly solutions that significantly minimize waste and harmful chemical use compared to traditional methods. Businesses and consumers alike are becoming increasingly conscious of their environmental impact, and DTF transfers cater precisely to this need, making them a preferred choice for custom printing solutions. The flexibility of DTF printing also supports fast production printing, ensuring that brands can meet the demands of a fast-paced market without compromising quality. This introductory exploration will delve deeper into the myriad benefits of DTF transfers, setting the stage for a future that prioritizes sustainability in every aspect of the printing industry.

Understanding DTF transfers can be articulated through various synonymous terms that capture its essence. Known alternatively as Direct-to-Film printing, this innovative method facilitates the application of designs onto fabric with remarkable precision and speed. Many practitioners also refer to it as eco-friendly transfers, owing to its significantly lower environmental footprint compared to traditional techniques. With the evolution of fast production printing, DTF technology enables businesses to adapt rapidly to market demands while offering tailored custom printing solutions. This descriptive overview sets the groundwork for understanding why adopting DTF technology is essential for modern-day printing endeavors.

Understanding DTF Transfers: A Sustainable Printing Revolution

Direct-to-Film (DTF) transfers represent a revolutionary step in the printing industry, particularly in the realm of sustainable printing solutions. This method stands out by utilizing eco-friendly materials that minimize waste during the production process. By focusing on sustainable practices, DTF transfers eliminate the excessive ink usage and harmful chemicals commonly associated with traditional printing methods. This makes DTF not only a preferable choice for businesses looking to reduce their environmental impact but also a favorite among consumers who value sustainability.

Notably, DTF technology not only champions eco-friendliness but also embodies efficiency. The process is streamlined and designed to optimize resources, allowing for a reduced carbon footprint while maintaining high-quality output. This unique balance of sustainability and quality positions DTF transfers as a modern solution for apparel production in an industry increasingly leaning towards responsible practices.

The Efficiency Edge of DTF Transfers: Speed and Quality Combined

In today’s fast-paced market, where consumer demands are continuously evolving, efficiency is critical. DTF transfers offer significant advantages in production speed over traditional methods. Unlike traditional printing, which often involves complex setups and lengthy processing times, DTF technology allows for quick turnarounds to meet urgent orders without compromising on quality. This capability is essential for brands that must keep up with fast fashion cycles and fluctuating consumer trends.

Moreover, the ability of DTF transfers to work on various fabric types further enhances their efficiency. With options ranging from cotton to polyester, businesses can easily switch between materials without the need for specialized equipment or extensive setup changes. This versatility is not only a time-saver but also supports a wider array of creative applications in custom printing solutions, making DTF a formidable player in the market.

Custom Printing Solutions with DTF: Empowering Creativity

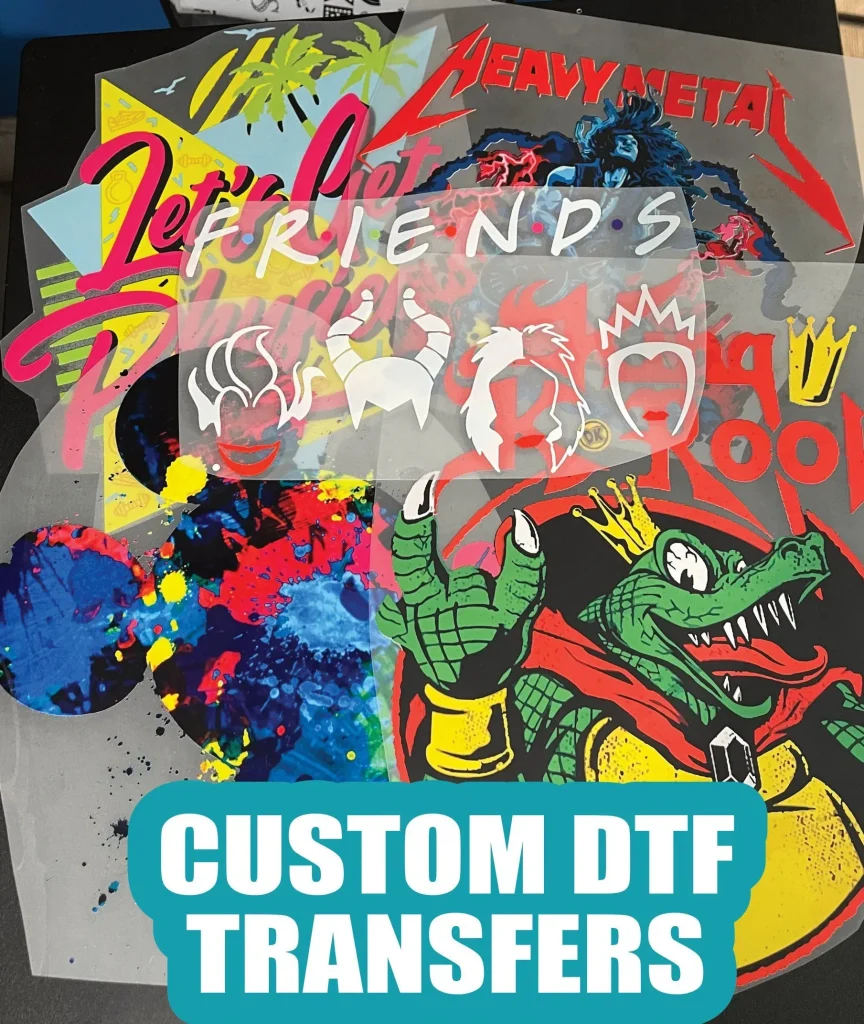

One of the standout features of DTF transfers is their ability to cater to user empowerment and customization. Unlike traditional printing methods that require substantial setup time and material investment, DTF technology allows individuals and businesses alike to create tailored designs swiftly. This innovation has transformed the landscape for crafters and small business owners, enabling them to access custom printing solutions that were once reserved for large-scale operations.

Furthermore, the accessibility of DTF technology promotes creativity in design. With user-friendly services emerging in the market, consumers can enjoy the process of designing their apparel without the barriers traditionally associated with custom printing. This democratization of printing technology not only enhances customer satisfaction but also fosters a community of creators who can bring their unique visions to life.

Comparing DTF Transfers and Traditional Methods: Quality Matters

When it comes to assessing printing methods, the quality of the final product is paramount. DTF transfers offer vibrant and durable prints that often surpass the results achieved through traditional screen printing techniques. Over time, screen-printed designs can fade and deteriorate, whereas DTF prints are formulated to withstand wear and maintain their aesthetic appeal. This quality advantage makes DTF an appealing choice for brands seeking to deliver lasting products to their customers.

Moreover, DTF technology enables quicker adjustments and prototyping, which is a significant benefit compared to the lengthy setup processes of traditional printing methods. In an age where speed to market can dictate success, this ability to rapidly make modifications is crucial for brands striving to stay competitive and responsive to consumer needs.

The Financial Benefits of DTF Transfers for Small Businesses

From a financial perspective, the adoption of DTF technology can yield substantial cost savings for small businesses and startups. Traditional printing methods often come with high setup costs and extended production timelines, making them less viable for businesses operating on tight budgets. In contrast, DTF transfers allow for more efficient use of resources, ultimately reducing overhead costs and increasing profit margins.

Additionally, by minimizing waste and leveraging faster production capabilities, businesses can enhance their operational efficiency. This economic edge allows small enterprises to reinvest savings into growth opportunities, such as expanding product lines or improving marketing strategies, positioning them for long-term success in an increasingly competitive market.

Innovations Driving the Future of DTF Technology

The evolution of DTF printing technology has been significantly influenced by recent industry innovations. Companies such as Snuggle and Eazydtf are leading the charge by introducing services and technologies that make DTF transfers more accessible to businesses of all sizes. These innovations not only lower the entry barriers for adopting DTF technology but also ensure that businesses can leverage advanced printing capabilities without incurring substantial upfront costs for equipment.

As the market continues to innovate, the potential for DTF transfers to revolutionize the printing landscape becomes increasingly apparent. These advancements reflect a growing acknowledgment of the widespread benefits of sustainable and efficient printing methods, hinting at a promising future for DTF technology that aligns with both environmental responsibility and business efficiency.

Frequently Asked Questions

What are DTF transfers and how do they differ from traditional printing methods?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique that allows for high-quality designs to be printed directly onto film before being transferred onto various fabrics. Unlike traditional printing methods, which often require complex setup and can generate more waste, DTF transfers are known for their efficiency, reduced waste, and ability to print on a wide range of fabrics.

How do DTF transfers promote sustainable printing practices?

DTF transfers promote sustainable printing by minimizing material waste and avoiding the use of harmful chemicals commonly found in traditional printing methods. This eco-friendly approach not only reduces environmental impact but also appeals to consumers who prioritize sustainability in their purchasing decisions.

What are the advantages of using DTF transfers for custom printing solutions?

The advantages of using DTF transfers for custom printing solutions include rapid production speeds, the ability to easily customize designs, and compatibility with various fabric types. This flexibility allows businesses to meet diverse customer needs while maintaining high-quality output, making it an ideal choice for those looking to offer personalized products.

Can DTF transfers be used for fast production printing?

Yes, DTF transfers are ideal for fast production printing as they offer quicker turnaround times compared to traditional methods. This capability allows businesses to respond to urgent order requests efficiently without compromising on print quality, making DTF an excellent option for high-volume production.

What types of fabrics can DTF transfers be applied to?

DTF transfers can be applied to a wide variety of fabrics, including cotton, polyester, blends, and many others. This versatility expands the creative possibilities for designers and brands, allowing them to utilize DTF technology across different apparel applications.

How do DTF transfers compare in quality to traditional printing techniques?

In terms of quality, DTF transfers generally provide vibrant, durable images that resist fading over time, surpassing the results of traditional screen printing methods. This quality difference is crucial for businesses that aim to deliver long-lasting products and satisfied customers.

| Key Points | DTF Transfers | Traditional Methods |

|---|---|---|

| Sustainability and Efficiency | Utilizes more sustainable practices, significantly reducing material waste. | Often involves significant waste and harmful chemicals. |

| Flexibility in Production | Faster turnaround times, suitable for various fabric types. | Longer setup times and limited to specific materials. |

| Customization Opportunities | Empowers users to create tailored designs easily. | Custom printing processes can be cumbersome and less accessible. |

| Economic Advantages | Reduces operational costs and improves profit margins. | Higher setup costs and longer production time. |

| Quality and Durability | Offers vibrant, durable results that don’t fade quickly. | Screen printing can fade over time and may lack vibrancy. |

Summary

DTF transfers represent a revolutionary shift in the printing industry, offering a sustainable, efficient, and customizable alternative to traditional printing methods. As businesses increasingly prioritize eco-friendly solutions in their production processes, DTF transfers stand out with their ability to reduce waste, enhance production speed, and deliver high-quality, durable designs. The growing demand for these innovative techniques indicates that DTF transfers are not just a fleeting trend but a robust solution that meets modern consumer expectations. Embracing DTF technology can empower both brands and consumers towards a more sustainable future in apparel production.