DTF transfers, or Direct to Film transfers, are revolutionizing the printing industry with their remarkable versatility and ease of use. This innovative DTF printing technology allows for high-quality designs to be applied to a wide range of fabrics, making it an excellent choice for both small businesses and personal projects. As we dive into the pros and cons of DTF transfers, you’ll discover how this method stacks up against traditional printing techniques, particularly when considering its cost-effectiveness and overall efficiency. Furthermore, we will highlight various DTF transfer applications that showcase its potential across different fields, from custom apparel to promotional items. By understanding the benefits and challenges associated with DTF, you can make informed decisions on whether this printing method is suitable for your needs.

As the demand for advanced printing solutions continues to grow, Direct to Film printing has emerged as a top contender in the realm of garment decoration. Often compared to other methods like sublimation, DTF transfers offer unique advantages that cater to a diverse array of materials and applications. The process of using film-based transfers not only enhances the printing quality but also introduces a level of compatibility with dark fabrics that other techniques struggle to achieve. By examining the landscape of DTF technology, we can explore its various uses, including crafting custom clothing and producing promotional merchandise that stands out. Unlocking the full potential of this innovative printing approach requires an understanding of its underlying principles and practical considerations.

Understanding DTF Transfer Technology

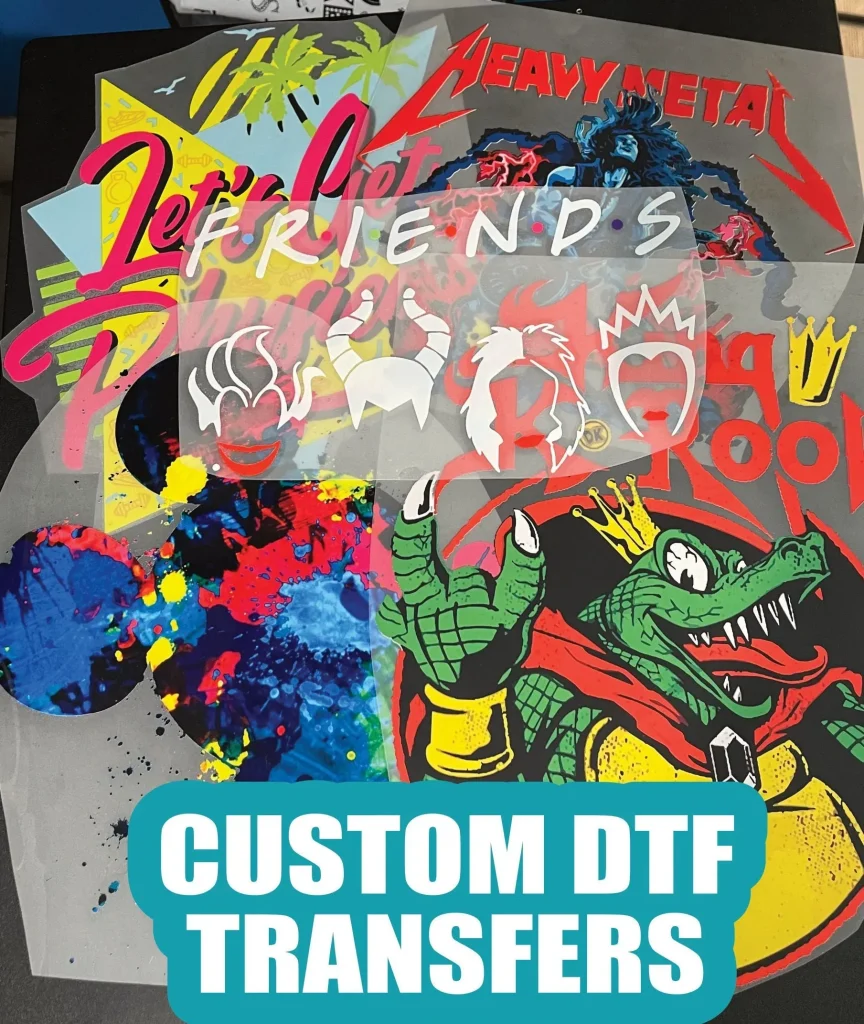

Direct to Film (DTF) transfers have revolutionized the garment printing industry with their innovative approach to applying designs onto fabrics. Unlike traditional printing techniques such as screen printing and sublimation, DTF printing replaces the need for direct ink application on the substrate by first printing on a special film. This film is then transferred onto the material, allowing for exceptional detail, vibrant colors, and durability. Since DTF can be applied to a wide range of fabrics, including cotton and polyester blends, it becomes a versatile solution for custom apparel printing.

The technology behind DTF transfers involves specific printers, inks, and films, which must work together seamlessly to achieve quality results. DTF printers utilize specialized inks formulated to bond well with various substrates when heat pressed. This process not only enhances the transfer’s adhesion to the fabric but also ensures that the printed image remains intact even after numerous washes. As DTF transfer applications grow, more businesses and individuals are investing in this technology to streamline their printing needs.

Frequently Asked Questions

What are the pros and cons of DTF transfers?

DTF transfers offer several advantages, including compatibility with various fabric types, cost-effectiveness for dark fabrics, and user-friendly setup, making them ideal for beginners. However, potential downsides include high initial equipment costs, a heavier feel on garments compared to sublimation printing, and the technical challenges of achieving optimal transfer results.

How does DTF printing technology compare to sublimation printing?

DTF printing technology differs from sublimation in that it can print on a wider range of fabrics, including cotton and dark materials. In contrast, sublimation only works effectively on polyester. Consequently, DTF transfers may be more versatile in applications where fabric type varies.

What are some common DTF transfer applications?

Common applications of DTF transfers include custom apparel like t-shirts and hoodies, promotional items such as branded caps and bags, unique craft projects, and designs on sportswear and activewear. This technology is widely used for various creative and commercial printing needs.

What advantages do DTF equipment offer for small businesses?

DTF equipment offers several advantages for small businesses, including cost-effective printing on darker fabrics without the need for special materials, fast production times for fulfilling orders, and ease of use, making it accessible for those new to garment printing.

Is DTF printing beginner-friendly compared to other methods?

Yes, DTF printing is considered more beginner-friendly than other methods like sublimation or screen printing. Its setup and application processes typically involve fewer complex steps, making it easier for hobbyists and small business owners to start producing quality prints.

What should I consider before investing in DTF transfers?

Before investing in DTF transfers, consider the initial equipment costs, the variety of fabrics you plan to print on, the learning curve associated with the technology, and how DTF’s advantages align with your business goals and production needs.

| Advantages | Disadvantages | Applications |

|---|---|---|

| Wide Fabric Compatibility – Suitable for various fabric types including cotton and dark fabrics. | Initial Equipment Costs – High upfront costs for printers and supplies may be a barrier for some. | Custom Apparel – Ideal for printing designs on t-shirts, hoodies, etc. |

| Cost-Effectiveness – Reduces costs, especially for dark clothing where sublimation fails. | Heavier Feel on Fabrics – Transfers can feel heavier compared to sublimation prints. | Promotional Items – Great for branded merchandise like caps and bags. |

| Easier to Use – User-friendly for beginners and efficient for small businesses. | Technical Challenges – Requires precision in temperature and pressure settings. | Craft Projects – Perfect for personalized items for gifting or events. |

| Fast Production Times – Quick turnarounds for fulfilling larger orders without sacrificing quality. | Sportswear and Activewear – Suitable for performance fabrics, expanding options for designers. |

Summary

DTF transfers represent a significant advancement in printing technology, providing a versatile and effective method for transferring designs onto various fabric types. This innovative approach offers a blend of affordability, broad applicability, and ease of use, making it a popular choice among both novice crafters and established businesses. While the initial investment in equipment can be considerable, the potential for cost savings in production and the ability to create high-quality custom apparel and promotional items make DTF transfers an appealing option. Ultimately, understanding the pros and cons of DTF transfers will empower users to make informed decisions that align with their creative and business goals.