DTF transfers, or Direct-to-Film transfers, represent a revolutionary leap in the world of custom T-shirt printing. This innovative technology allows for vibrant, high-quality designs to be printed directly onto a specially prepared film, which can then be transferred onto various fabrics using a heat press. Unlike traditional methods, DTF printing delivers stunning colors and intricate details with efficiency, making it an appealing choice for businesses and creators alike. The growing popularity of DTF transfers highlights their capacity to meet the demand for personalized apparel, reflecting individual style and branding. As we delve deeper into this topic, we will explore how DTF printing not only enhances T-shirt printing solutions but also streamlines the creative process, offering endless possibilities for custom T-shirt designs.

When discussing modern fabric printing techniques, the term “Direct-to-Film technology” often comes to the forefront. This advanced method revolutionizes the realm of T-shirt creation, enabling the production of eye-catching, detailed graphics that cater to the need for custom apparel. With the rise of personalized clothing, DTF transfers have gained traction among both entrepreneurs and creative individuals seeking reliable T-shirt printing solutions. This approach to design application is not only efficient but also versatile, adapting seamlessly to a variety of fabric types. As we further investigate the benefits and applications of these transfers, we will uncover the transformative impact they have on the custom T-shirt market.

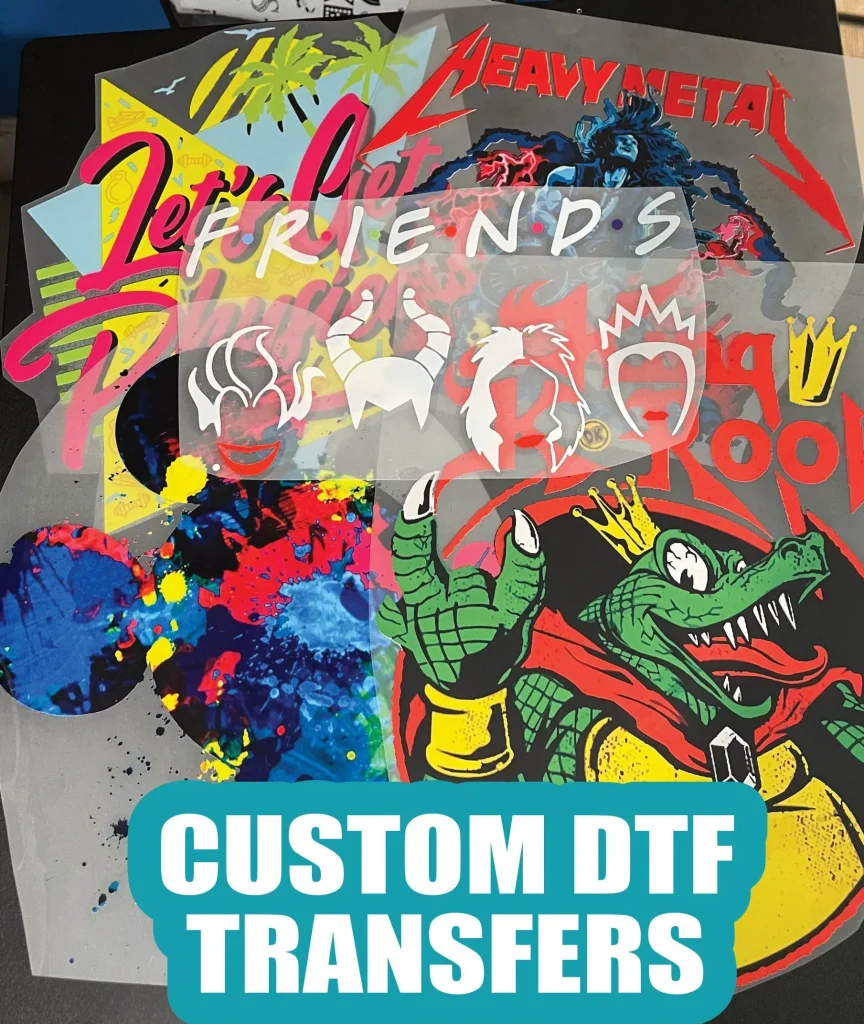

Understanding DTF Transfers: The Future of T-Shirt Printing

DTF transfers, or Direct-to-Film transfers, are changing the landscape of custom T-shirt printing. By utilizing a unique process where inks are printed onto a special film, these transfers allow for full-color designs to be applied to various fabrics with remarkable precision. This innovation not only enhances the final product’s quality but also provides unmatched flexibility in terms of design complexity and fabric compatibility. As e-commerce continues to rise, understanding the advantages of DTF technology is crucial for anyone looking to stand out in the apparel market.

One of the major selling points of DTF transfers is their ability to deliver vibrant T-shirt designs with high-quality prints that maintain their integrity through multiple washes. The technology employs advanced ink formulations that ensure colors remain rich and true over time. This durability, combined with the ease of application, makes DTF transfers an appealing choice for both businesses and individual creators seeking to explore custom T-shirt printing solutions.

The Advantages of DTF Printing Over Traditional Methods

When comparing DTF printing to traditional methods such as screen printing, the benefits are striking. DTF transfers allow for quicker production times, which is essential in today’s fast-paced market. A standard workflow for traditional printing may involve lengthy setup times and multiple screens, causing delays in order fulfillment. In contrast, DTF printing simplifies the process, enabling businesses to rapidly produce high-quality custom apparel without sacrificing quality or detail.

Another significant advantage is the cost-effectiveness of DTF technology. Businesses can reduce overhead by using no-minimum order requirements offered by companies like Sam’s DTF Transfers. This offers startups an opportunity to enter the market without committing to large inventory purchases, enabling a more sustainable business model. As a result, the accessibility of DTF transfers makes it possible for aspiring designers and small businesses to thrive in the growing custom printing landscape.

DTF Printing: A Game Changer for Customization

Customization is at the forefront of modern consumer desires, and DTF printing meets this demand head-on. With the ability to print intricate designs in full color on a broad range of fabrics, DTF transfers enable creators to offer unique T-shirt printing solutions that cater to various client needs. Whether it’s a personalized birthday gift or a branded merchandise line, this technology empowers both hobbyists and professionals to bring their creative visions to life swiftly and effectively.

Additionally, the capacity to make on-the-fly modifications to designs means that DTF printing is particularly suited for small runs and short lead times. Businesses looking to capitalize on trends or create seasonal lines can do so quickly, reducing inventory costs and allowing for better responsiveness to market changes. This adaptability is a defining feature of DTF transfers, reshaping how bespoke apparel is conceived and created.

Transform Your Business with DTF Technology

For businesses seeking to enhance their offerings, embracing DTF technology can be transformative. With the capability to turnaround orders rapidly and a wide variety of finishes available, companies can cater to diverse market segments while minimizing production bottlenecks. This flexibility allows them to tackle both bulk orders for established client bases and smaller, personalized requests, providing a comprehensive portfolio of services.

Moreover, DTF printing opens up additional revenue streams. Through the promotion of personalized T-shirts and other wearable merchandise, businesses can engage with customers on a deeper level, fostering brand loyalty and increasing repeat sales. By capitalizing on the strong demand for custom apparel, businesses that integrate DTF technology can stay ahead of the competition in an ever-evolving retail environment.

Ensuring Quality Control in DTF Printing

Quality control is paramount in any printing process, and DTF technology offers unique solutions to ensure that every print meets the highest standards. By adopting stringent testing measures and employing advanced printing techniques, companies can effectively monitor output to guarantee consistency in color and design. This approach builds trust with consumers, as customers can expect reliability in the products they receive.

Furthermore, investing in high-quality DTF materials such as films and inks can significantly enhance the final product’s quality. By choosing trusted suppliers and maintaining high manufacturing standards, businesses can minimize issues related to color fading and print adhesion. Thus, focusing on quality control is essential for any company looking to establish a strong reputation in the custom T-shirt printing industry.

The Future of Custom T-Shirt Printing with DTF Transfers

As we look to the future, the potential of DTF transfers in the realm of custom T-shirt printing seems boundless. With ongoing advancements in printing technology and materials, we can expect further enhancements in print quality, speed, and efficiency. Companies investing in DTF technology are not just adapting to current market demands; they are also innovating ways to deliver even more engaging and personalized products to consumers.

Additionally, consumer preferences are continually evolving, with a growing emphasis on sustainability and ethical production practices. DTF printing’s potential to minimize waste through on-demand printing aligns perfectly with these trends, making it an appealing choice for environmentally conscious businesses. The continued adoption of DTF technology will undoubtedly play a critical role in shaping the future landscape of the custom T-shirt printing industry.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, utilize special inks printed onto a film that are then transferred onto fabric using a heat press. This innovative technology allows for vibrant, full-color designs to be printed on various fabrics including cotton and polyester.

What makes DTF printing a better option for custom T-shirt printing?

DTF printing is a superior option for custom T-shirt printing as it offers high-quality, vibrant designs with quick turnaround times. It’s versatile and can adhere to a range of fabrics, making it ideal for personalized apparel.

Can DTF Transfers be used on all types of fabrics?

Yes, DTF Transfers are highly versatile and can be applied to a wide variety of fabric types including cotton, polyester, and blends. This adaptability makes DTF printing suitable for custom apparel in many different contexts.

How does the print quality of DTF Transfers compare to other printing methods?

The print quality of DTF Transfers is often superior, featuring vibrant colors and clarity that rivals traditional methods like screen printing. The advanced ink formulations used in DTF ensure durability, keeping designs intact through multiple washes.

Why are DTF Transfers more cost-effective for small T-shirt printing orders?

DTF Transfers are cost-effective due to their no-minimum order requirements, allowing small businesses and startups to produce custom T-shirts without the burden of large initial investments, making it a budget-friendly solution.

What role do DTF Transfers play in sustainable T-shirt printing practices?

DTF Transfers contribute to sustainable T-shirt printing by minimizing waste. They generate only the necessary transfers needed for each order, reducing excess stock and aligning with eco-friendly practices in the apparel industry.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers use special inks on a film that can be heat-pressed onto various fabrics. They offer versatility compared to traditional methods. |

| The Rise of DTF Technology | Increasing demand for personalized clothing due to e-commerce growth has elevated DTF transfers’ popularity. |

| Recent Developments | 1. Sam’s DTF Transfers provides premium no-minimum custom solutions. 2. DTFPrinter offers custom transfer services focusing on crafters with high-quality transfers. 3. Adoption of DTF technology continues to grow. |

| Benefits of DTF Transfers | 1. Efficiency in production with quicker turnaround. 2. High-quality prints with vibrancy and clarity. 3. Versatility across various fabrics. 4. Cost-effective for small orders. 5. Customization at scale. |

| Empowerment through DTF Transfers | DTF technology democratizes access to custom printing, allowing hobbyists and small businesses to enter the market. |

| Sustainability | DTF transfers produce less waste compared to traditional methods, aligning with sustainable practices in the industry. |

Summary

DTF Transfers are transforming the landscape of T-shirt printing by allowing for the creation of vibrant, high-quality designs with remarkable efficiency. This groundbreaking printing technology has made it possible for creators and small businesses to produce custom apparel that meets the demands of today’s market for personalization and quick turnaround. As companies like Sam’s DTF Transfers and DTFPrinter innovate within this space, it’s clear that DTF Transfers are not just a trend but a key tool for anyone looking to elevate their custom apparel offerings.