DTF transfers, short for Direct to Film transfers, have become a game-changer in the textile printing industry, allowing for stunning designs to be printed onto various fabrics with ease. This innovative printing method boasts vibrant colors and exceptional detailing, yet it’s not without its challenges. Many users may encounter DTF printing issues such as ink smudging, poor adhesion, or unanticipated color discrepancies that hinder the overall quality of their prints. In this guide, we’ll delve into effective troubleshooting techniques and DTF transfer solutions to overcome these common problems, ensuring your prints are always eye-catching and durable. Whether you’re a beginner or an experienced printer, understanding these nuances can significantly improve your DTF transfer results.

Also known as Direct to Film printing, this method has taken the world of garment decoration by storm, offering an efficient solution for transferring vibrant designs to various materials. While DTF printing presents numerous advantages, users often face some heat press problems and adhesion issues that can complicate the process. By exploring the intricacies of transfers troubleshooting, we aim to equip you with the knowledge needed to avoid common pitfalls and enhance your printing experience. The insight provided here not only addresses prevalent challenges but also covers best practices and resources that can lead to successful and impressive DTF transfer outcomes. With the right know-how, you can make the most of this remarkable printing technology.

Understanding DTF Transfers and Their Issues

DTF (Direct to Film) transfers are a modern printing technique that allows users to create vibrant and durable designs on a variety of fabric surfaces. This method involves printing the design onto a special film, which is then transferred to the garment using a heat press. While DTF technology boasts numerous advantages, it’s not without its challenges. Users often encounter several DTF printing issues that can compromise the quality of their prints, making it essential to understand these problems before diving into production.

Common dilemmas, such as ink smudging or poor adhesion, often stem from improper settings during the printing or transfer process. For instance, using incorrect temperature settings can lead to insufficient curing of the ink, resulting in smudged designs that are unattractive and unprofessional. As users navigate the world of DTF presses, a firm grasp on these common issues will enable them to troubleshoot effectively and enhance the overall quality of their printed garments.

Common DTF Printing Issues: Ink Smudging and Blurring

One of the prevalent issues in DTF printing is ink smudging or blurring, which undermines the vibrancy and clarity of designs. This often occurs due to inadequate curing, insufficient temperature, or incorrect application techniques during the transfer. Users should always verify their heat press settings to ensure they align with the guidelines provided by the manufacturer of the DTF film. Keeping the temperature within the recommended range not only helps to avoid smudging but also ensures that the ink adheres properly to the substrate.

It’s crucial to note that allowing the ink to cure fully before the transfer is applied is a vital step. Rushing this process can lead to poor adhesion and the eventual smearing of designs. To overcome these issues, users should implement a systematic approach that includes timing each stage of the process meticulously and regularly checking equipment settings for accuracy. Creating a checklist for the transfer process can help maintain consistency and reduce the chances of failure.

Addressing Poor Adhesion in DTF Transfers

Poor adhesion during DTF transfers can lead to peeling and lifting of designs shortly after application, causing frustration for users expecting long-lasting results. This problem often arises from the use of substrates that aren’t compatible with DTF transfers or inadequate pre-treatment of fabrics before printing. To address adhesion issues, it is essential to select the appropriate fabric types that allow for strong bonding with the transfer, such as cotton or polyester blends.

In addition to selecting the right substrate, users should consider pre-treating their fabrics, especially if they are working with materials that tend to repel ink. Proper pre-treatment can significantly improve adhesion, ensuring that designs stay intact for their intended lifespan. Moreover, applying sufficient pressure during the heat press operation is crucial, as insufficient pressure can lead to weaker bonds. It’s recommended that users calibrate their machines to achieve the optimal pressure needed for effective transfers.

Color Discrepancies with DTF Transfers: Troubleshooting

Color discrepancies are another common issue faced by DTF transfer users, where the final print fails to match the original design as seen on screen. These variances often arise from outdated or incorrect ICC profiles, leading to inaccurate color representations. To avoid this problem, users must ensure that they are utilizing the latest ICC profiles provided by their DTF film manufacturer. Consistently updating these profiles can drastically improve color accuracy in printed designs.

Additionally, regular calibration of printing equipment is essential for maintaining color consistency. Calibration helps align the color output with the digital design, reducing the potential for inaccuracies. Users should also run test prints to visually check color accuracy before starting full production runs. By implementing these practices, the likelihood of color discrepancies occurring in DTF transfers can be significantly reduced, leading to higher satisfaction with the final product.

Minimizing Cracking and Peeling During Application

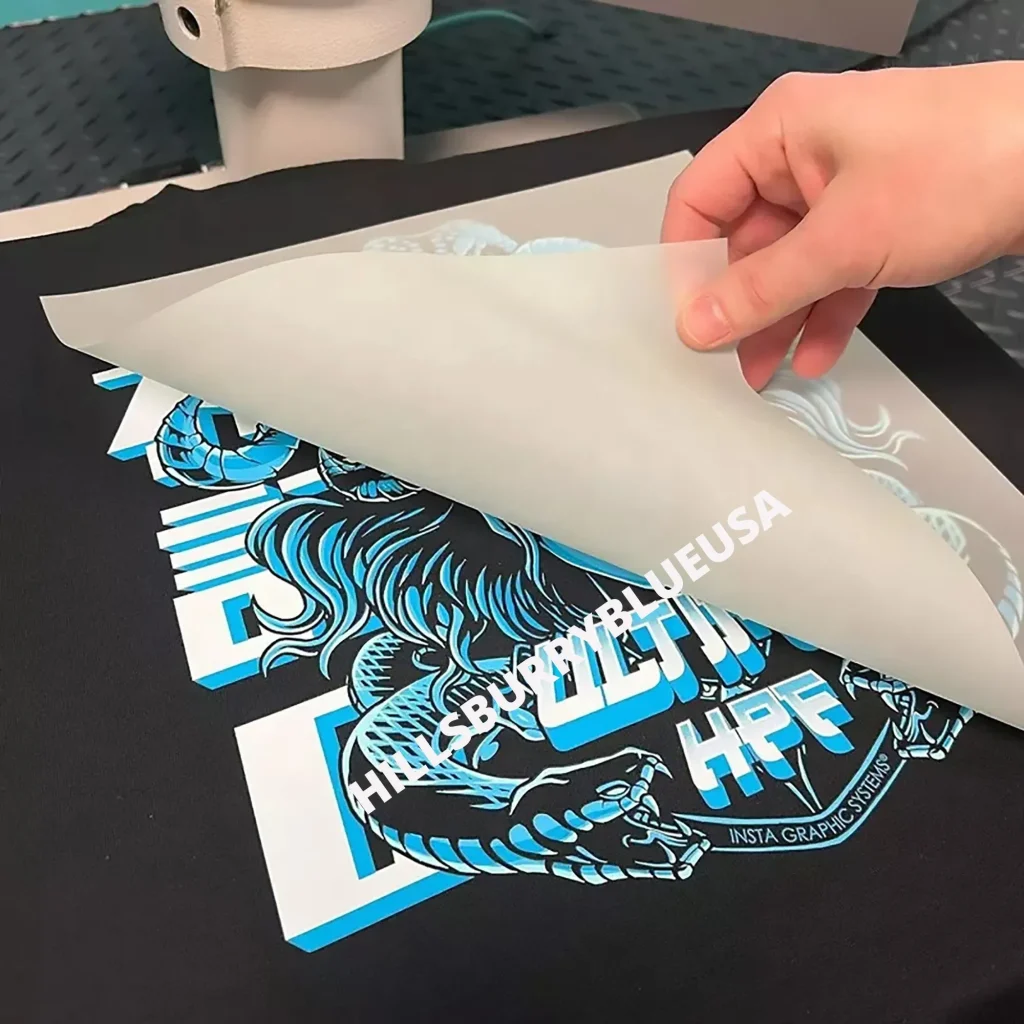

Cracking or peeling of DTF transfers often occurs when the application is not executed correctly. To minimize these issues, users should adhere to the recommended temperature settings as specified by the transfer film’s manufacturer. Ensuring that the heat press is set to the correct temperature is vital to achieving a successful transfer; insufficient heat can prevent proper bonding, resulting in cracks or separation after peeling.

Another critical factor is the technique used when peeling the film away from the garment. Abrupt or hasty removal can cause the transfer to lift prematurely. A better practice is to allow the transfer to cool slightly before peeling the film, as this promotes stronger adhesion between the design and the fabric. Incorporating this simple step can greatly improve the durability of DTF transfers while reducing the risk of cracking.

Best Practices for Successful DTF Transfers

Implementing best practices in DTF transfers is essential for achieving professional results while avoiding common troubleshooting pitfalls. One such practice includes investing in high-quality supplies, such as transfer films, inks, and reliable heat presses. The quality of materials used can dramatically influence the performance of DTF transfers, with subpar materials often leading to increased defects and poor adhesion.

Regular calibration and maintenance of printing equipment is also paramount. By ensuring that ink and print head systems are clean and fully functional, users can minimize the chances of experiencing common issues such as ink smudging or inadequate ink flow. Additionally, conducting test transfers on sample materials before initiating large production runs allows for fine-tuning settings to match desired outcomes without risk to time and resources.

Frequently Asked Questions

What are common DTF printing issues that I should be aware of?

Common DTF printing issues include ink smudging, poor adhesion, color discrepancies, and cracking or peeling of the transfer. Each of these problems can typically be traced to factors such as improper temperature settings, substrate compatibility, or outdated ICC profiles.

How can I troubleshoot poor adhesion in my DTF transfers?

To troubleshoot poor adhesion in DTF transfers, ensure that you are using a compatible substrate, consider pre-treating the fabric if necessary, and apply sufficient pressure during the heat pressing process. Also, verify that you are using the right temperature settings according to the manufacturer’s guidelines.

What should I do if I experience color discrepancies with my DTF transfers?

If you encounter color discrepancies in your DTF transfers, check to see if you are using the latest ICC profiles provided by your film manufacturer. Regular calibration of your printer can also help maintain color accuracy and consistency across prints.

What causes cracking or peeling in DTF transfers, and how can I prevent it?

Cracking or peeling in DTF transfers can be caused by applying the transfer at incorrect temperature settings or peeling the film too quickly. To prevent this, follow recommended temperature guidelines and allow the transfer to cool slightly before removing the film.

What best practices should I follow to ensure successful DTF transfers?

To ensure successful DTF transfers, invest in high-quality materials, regularly maintain and calibrate your printing equipment, conduct test transfers on sample materials, and keep your printer clean to avoid clogs.

Where can I find additional resources for troubleshooting DTF transfer issues?

You can find additional resources for troubleshooting DTF transfer issues in manufacturer guidelines, online community forums focused on DTF printing, and video tutorials available through established printing communities.

| Issue | Description | Solutions |

|---|---|---|

| Ink Smudging or Blurring | Occurs due to improper curing or insufficient heat during the transfer process. | – Check temperature settings of the heat press. – Verify that the DTF film is fully cured before application. |

| Poor Adhesion | Leads to lifting or peeling of the design after transfer. | – Ensure substrate compatibility with DTF transfers. – Perform necessary fabric pre-treatment. – Apply adequate pressure during pressing. |

| Color Discrepancies | Colors may not appear as expected on the final print. | – Update to the latest ICC profiles. – Regularly calibrate printing equipment. |

| Cracking or Peeling | May occur from incorrect application of the transfer. | – Follow recommended temperature settings. – Use correct peeling techniques. |

Summary

DTF Transfers are transforming the printing landscape by enabling high-quality prints on various fabrics, but they can present challenges that affect print quality. Understanding and troubleshooting common issues like ink smudging, poor adhesion, color discrepancies, and cracking is crucial for achieving professional results. By implementing best practices such as careful calibration, regular maintenance, and utilizing available resources, you can enhance your DTF printing experience. Continuous engagement with community forums and adherence to manufacturer guidelines will keep you well-informed on the latest advancements in DTF Transfers, ultimately leading to more vibrant and durable designs.