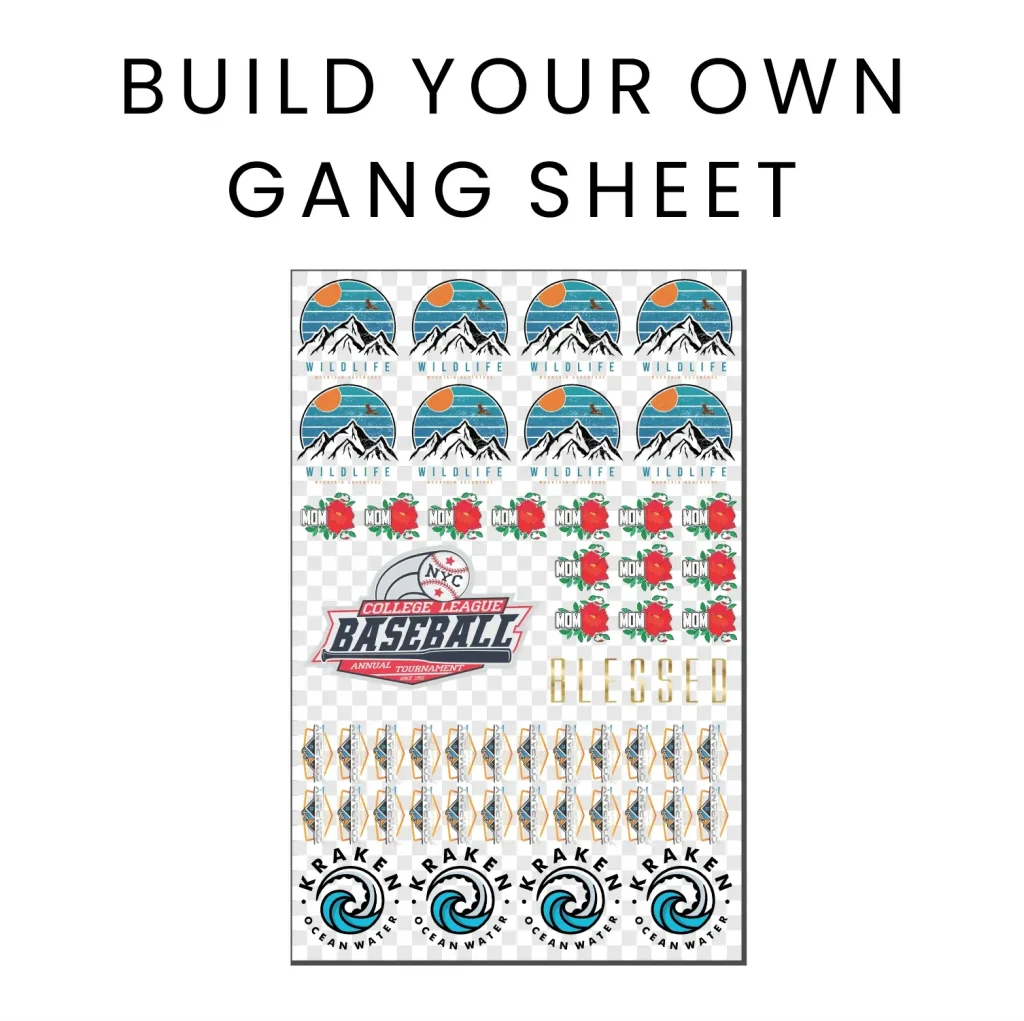

The DTF gangsheet builder has revolutionized the way enthusiasts and professionals approach Direct-to-Film (DTF) printing, a process celebrated for its stunning and durable results on various fabrics. By optimizing the layout through a gangsheet, users can effectively nest multiple designs, maximizing film utilization and reducing waste. This innovative tool is complemented by other essential DTF printing tools, including high-quality DTF printers and reliable adhesive powder for DTF application. Moreover, mastering the heat press machine is vital in ensuring that transfers adhere perfectly to textiles, allowing for vibrant, long-lasting prints. In this guide, we will delve deeper into how you can harness these resources, including design software for DTF, to unlock your creative potential in the textile printing world.

The DTF gangsheet builder, an integral aspect of Direct-to-Film printing, enables the creation of efficient design layouts that optimize material usage. This advanced tool enhances productivity for both casual crafters and commercial printers alike by allowing multiple designs to be printed simultaneously. To fully embrace this printing method, it’s important to understand the accompanying tools, such as top-tier printers and special adhesive powders tailored for DTF applications. Additionally, having a dependable heat press machine can make all the difference in producing high-quality transfers. As we explore this topic, you will learn how to effectively combine these elements to elevate your fabric printing projects.

The Importance of Using Quality DTF Printing Tools

When diving into DTF printing, utilizing quality printing tools is non-negotiable. Tools like high-resolution DTF printers and the right transfer film are foundational to achieving vibrant and accurate prints that resonate with your audience. Brands such as Epson and Mimaki are known for their superior performance, ensuring that your prints not only look professional but also withstand the test of time. Remember, the vibrancy and durability of your prints largely hinge on the tools you invest in, making it essential to prioritize quality over cost.

In addition to printers, the ancillary materials such as DTF printing tools including heat press machines and adhesive powder play a crucial role in the process. A reliable heat press ensures that the transfer is executed flawlessly with consistent temperature and pressure, while adhesive powders tailored for DTF applications help the inks to bond effectively with the fabric. Investing in these tools will undoubtedly increase the quality of your print jobs and enhance customer satisfaction.

Navigating the Best DTF Printers for Your Needs

Choosing the best DTF printer can make a monumental difference in your printing outcomes. Many options are available on the market, but it’s essential to select a printer that aligns with your specific needs. Well-reviewed models from manufacturers like Epson and Mimaki are often highlighted for their print quality, speed, and reliability, making them worthwhile investments. These printers can handle a variety of materials and achieve the desired level of clarity in prints, which is vital for any serious DTF printing operation.

Furthermore, understanding the specifications of the printer you choose is crucial. Features such as print resolution, color accuracy, and compatibility with various software must align with your business requirements. Opting for a printer that supports high-quality output will not only benefit your projects but also foster growth in your business by attracting a more discerning customer base and fulfilling high-volume orders effortlessly.

The Role of Adhesive Powder in DTF Printing

The adhesive powder plays a pivotal role in Direct-to-Film printing processes, acting as a binding agent that guarantees the ink’s adherence to fabric. It’s essential to select a high-quality adhesive powder that is specifically designed for DTF applications. This enhances the vibrancy of prints and ensures that designs resist cracking or fading over time, allowing for superior long-term durability on various fabrics. Proper application techniques also matter vastly; even distribution of powder is necessary to avoid uneven transfers, which can adversely affect the final product.

Moreover, experimenting with different types of adhesive powders can yield intriguing results and expand your printing capabilities. There exist various formulations that respond differently to specific fabrics and designs, enabling you to push the boundaries of your creativity. Undertaking simple tests can help you determine the most effective combination of adhesive and application technique, ultimately elevating the quality of your prints.

Creative Design Software for DTF Printing

Design software is integral to the DTF printing process, enabling you to craft unique and compelling designs that capture attention. Popular programs like Adobe Illustrator and CorelDRAW offer versatile features that cater to both novice and experienced designers. By utilizing these tools, you can manipulate and arrange your designs for optimal gangsheet creation, ensuring that you maximize your film usage while creating stunning visual effects.

In addition to mainstream applications, free alternatives like Inkscape can provide excellent options for hobbyists or those new to DTF printing. These tools empower users to explore design techniques without a significant financial commitment. With the right design software, the potential for creativity in DTF printing is limitless, allowing you to not only meet but exceed customer expectations in the realm of printed apparel.

Utilizing Heat Press Machines Effectively

To ensure the success of your DTF printing process, utilizing a heat press machine effectively is paramount. This equipment not only transfers your design onto fabric but doing so with precision will directly impact the quality of your final product. Look for machines that allow you to adjust temperature and pressure settings accurately, as these factors are critical in ensuring that prints adhere well and maintain their vibrancy.

Additionally, regular maintenance of your heat press is essential for its longevity and optimal performance. Keep the heat plates clean and inspect the machines for any signs of wear or malfunction, ensuring that each transfer achieves uniform results. By establishing a consistent routine for checking and maintaining your machines, you can avoid issues that might lead to inconsistent print quality and, ultimately, unhappy customers.

Engaging with DTF Printing Communities for Continuous Learning

Engaging with communities dedicated to DTF printing can serve as a significant advantage for both beginners and seasoned professionals. Online forums and social media groups offer invaluable resources where members share experiences, troubleshooting tips, and creative ideas. These platforms provide a space to ask questions, celebrate successes, and initiate collaborations, all of which can contribute greatly to your growth as a DTF printer.

Networking with others in the DTF printing field not only expands your knowledge but also keeps you updated with the latest trends and technological advancements in the industry. By actively participating in these communities, you can learn from the challenges and successes of others, ensuring that you continuously evolve and innovate in your own projects. It’s a commitment to lifelong learning that will ultimately refine your skills and increase your competitive edge.

Frequently Asked Questions

What is a DTF gangsheet builder and why is it essential for DTF printing?

A DTF gangsheet builder is a tool that allows you to layout multiple designs efficiently on a transfer film for Direct-to-Film (DTF) printing. It’s essential because it maximizes material usage, reduces waste, and ensures that you can print multiple designs simultaneously, making the process more cost-effective.

What design software is best for creating prints with the DTF gangsheet builder?

The best design software for creating prints with a DTF gangsheet builder includes Adobe Illustrator for vector graphics, CorelDRAW for textile prints, and Inkscape as a cost-effective open-source option. These programs help ensure that your designs are professional and ready for high-quality DTF printing.

How important is the quality of the DTF printer when using a gangsheet builder?

The quality of the DTF printer is crucial when using a gangsheet builder. High-quality printers from brands like Epson and Mimaki deliver better color accuracy and resolution, ensuring vibrant and precise prints, which are essential for achieving the desired outcome in DTF printing.

What role does adhesive powder play in DTF gangsheet printing?

Adhesive powder in DTF gangsheet printing is used to ensure proper adhesion of the ink to the fabric after printing on the transfer film. The right type of adhesive powder, applied evenly, is critical for the transfer process to succeed, helping to avoid clumping and ensuring durable prints.

What settings should I consider on my heat press machine when using a DTF gangsheet?

When using a heat press machine with a DTF gangsheet, it’s vital to ensure consistent temperature and pressure settings. Precise adjustments are important to avoid issues like poor ink adherence or faded prints, so selecting a heat press that allows for accurate control is key.

Can I use standard transfer film with a DTF gangsheet builder?

No, you should use high-quality DTF transfer films specifically designed for the DTF printing process. These films are coated for better ink adhesion, which is essential for achieving vibrant, long-lasting prints on various fabrics.

| Key Elements | Details |

|---|---|

| Understanding DTF Printing | A printing method that transfers images from film onto fabric using heat and pressure, suitable for various materials such as cotton and polyester. |

| Design Software | Popular options include Adobe Illustrator for vector graphics, CorelDRAW for textile applications, and Inkscape as a beginner-friendly alternative. |

| Quality DTF Printer | Brands like Epson and Mimaki are recognized for their excellent color accuracy and resolution. |

| Transfer Film | High-quality, properly coated films that enable good ink adhesion. |

| Adhesive Powder | Use powder specifically for DTF, applied evenly to prevent clumping. |

| Heat Press Machine | Choose machines that allow precise control of temperature and pressure for optimal transfers. |

| Color Management Software | Color profiles that are compatible with your printer and software are crucial. |

Summary

The DTF gangsheet builder is an essential tool for anyone looking to excel in the realm of Direct-to-Film printing. By utilizing the right combination of quality tools and techniques, from design software to heat press machines, you can maximize the potential of your DTF projects. This guide highlights how mastering these components not only enhances the quality of your prints but also streamlines your workflow. As you deepen your understanding of DTF printing, you’ll discover that it’s not just a technical process but a creative avenue that allows for vibrant expression and innovation in textile design. Equip yourself with the best practices and embark on your journey to becoming a proficient DTF printer, ensuring that your prints stand out in today’s competitive market.