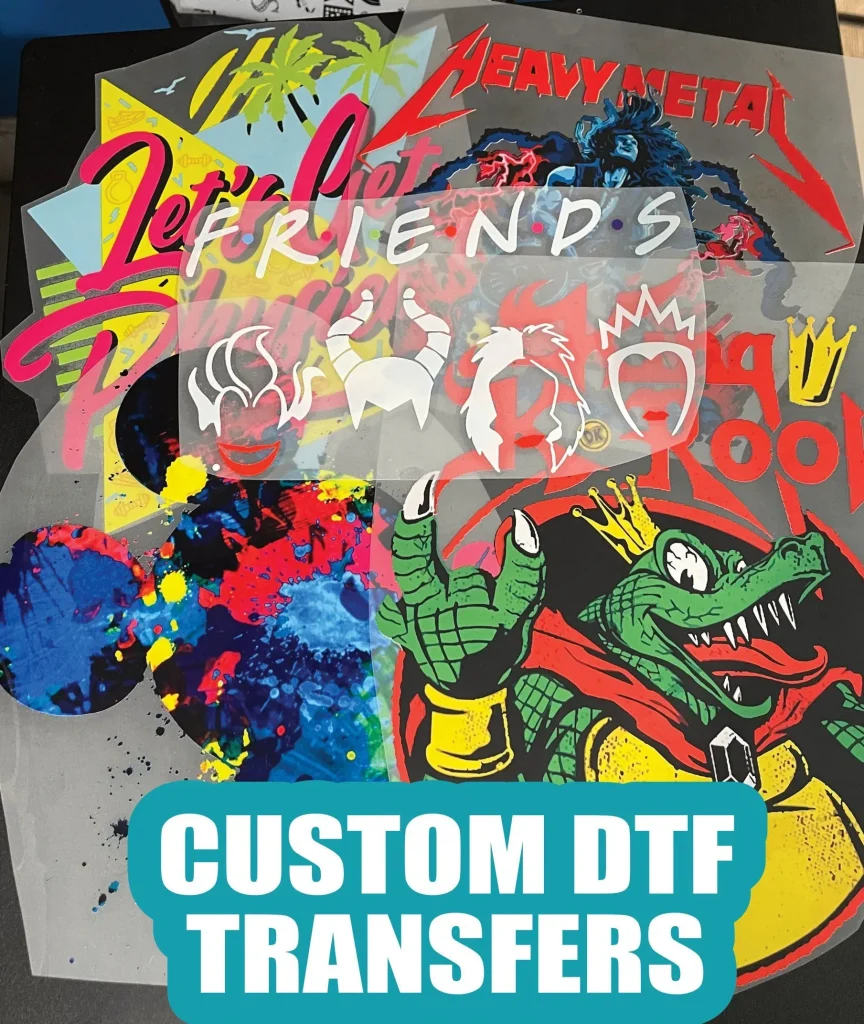

DTF transfers, short for Direct to Film transfers, are revolutionizing the custom garment printing landscape by offering vibrant, durable designs on various fabrics. Utilizing innovative DTF printing techniques, this process involves transferring high-quality images onto apparel with stunning color fidelity and resilience. From small businesses to DIY hobbyists, anyone can master DTF to create eye-catching designs that stand the test of time. Here in this article, we will explore 10 essential tips that will help you perfect your DTF transfers and elevate your printing skills. With the right approach and understanding of DTF film and adhesive applications, your creations can truly make a statement.

When it comes to fabric decoration, Direct to Film printing, also known as DTF printing, stands out as a remarkable method for achieving beautiful custom designs. The technology behind DTF transfers allows artists and entrepreneurs to apply intricate graphics onto various materials efficiently. By employing DTF transfer techniques, you’re not just enhancing the aesthetic appeal of your garments; you’re also ensuring long-lasting quality through robust adhesion and vibrant colors. With a strong focus on DTF films and the proper use of DTF adhesive, this method simplifies the complex world of custom garment printing, making it accessible for everyone.

Understanding DTF Printing Techniques

DTF printing is revolutionizing the garment printing industry, allowing creators to transfer intricate designs with ease. This innovative method involves printing onto a special DTF film, followed by sprinkling adhesive powder to secure the design before pressing it onto the fabric. One of the primary advantages of DTF printing is its versatility; it works exceptionally well on various fabrics including cotton, polyester, and blends. As a result, artists and businesses can achieve vibrant, high-quality prints that last.

Notably, the DTF transfer technique requires careful consideration of several aspects to ensure optimal results. From selecting the right film that accommodates the ink layer effectively to fine-tuning your printer settings, every step contributes to making your designs pop on garments. Understanding the nuances of DTF transfer techniques can be a game-changer for both hobbyists and professionals looking to enhance their printing capabilities.

Choosing the Right DTF Film

Selecting high-quality DTF film is pivotal for any successful transfer. The right film ensures that the ink adheres properly and produces vibrant colors, which is essential for creating eye-catching designs. With various films available on the market, it is advisable to experiment with different types to ascertain which one pairs best with your specific project needs. A good quality DTF film will showcase colors beautifully and maintain definition, even after multiple washes.

Moreover, understanding the specifications of your DTF film can save you time and prevent costly errors during your printing process. Films vary in thickness, adhesive properties, and compatibility with ink types. Doing thorough research and testing can lead to finding the optimal film that works seamlessly with your printing equipment and output goals. Choosing the right DTF film can significantly enhance the quality and durability of your printed designs.

Applying DTF Adhesive for Durable Transfers

The application of DTF adhesive powder plays a crucial role in ensuring that your designs adhere securely to the fabric during the heat transfer process. This step involves evenly sprinkling the adhesive over the wet ink after printing on the DTF film. For best results, it’s essential to apply the adhesive uniformly to avoid any inconsistencies that could affect the quality of the final product. A well-applied adhesive leads to durable and vivid designs that stand the test of time.

Additionally, handling the adhesive correctly is key to achieving successful transfers. Make sure to let the design sit for a few moments post-powdering; this allows the adhesive to bond well with the wet ink. Improper application can lead to peeling or fading of the design after washing. To ensure your DTF transfers are both visually appealing and long-lasting, take your time during the adhesive application process and follow all guidelines meticulously.

Fine-Tuning Your Heat Press Technique

Heat pressing is one of the most critical steps in the DTF transfer process. Applying the correct temperature and pressure can significantly influence the final outcome of your design. Ideally, the pressing temperature should be around 325°F for about 15-20 seconds; however, exact settings may vary depending on the fabric and specific guidelines from manufacturers. By paying attention to these parameters, you can prevent any issues such as fading or incomplete transfers.

It’s also beneficial to conduct trial runs on scrap fabric to determine the perfect heat press settings for your specific materials. This allows you to adjust the duration and temperature to achieve the best bond between the film, adhesive, and fabric. By mastering your heat press technique, you’ll ensure that your DTF transfers not only look stunning but are durable enough to withstand regular wear and washing.

Best Fabrics for DTF Transfers

One of the remarkable advantages of DTF transfers is their adaptability across various fabric types. Custom garment printing with DTF technology is successful on materials such as cotton, polyester, and blends. Understanding the characteristics of each fabric is crucial; some may require adjustments in the DTF transfer process to ensure optimal adherence and color fidelity. Testing on various fabrics prior to large runs can guarantee that your designs turn out perfectly.

Additionally, the choice of fabric can impact the appearance and feel of the finished product. While DTF transfers work well on dark and light fabrics alike, it’s important to choose materials that will enhance the vibrancy of the colors used. By carefully selecting the right fabrics, you can elevate the quality of your final design, ensuring that every DTF transfer reflects the hard work and creativity that has gone into it.

Ensuring Longevity Through Proper Care Instructions

To maintain the quality of your DTF transfers over time, it’s essential to provide customers with clear care instructions. Washing in cold water and avoiding direct sunlight will help preserve the vibrancy and integrity of the designs. Additionally, informing customers about the best practices for drying and ironing can prevent unintentional damage to the fabric and the print. By educating your clientele on how to care for their garments, you enhance their satisfaction and loyalty.

Moreover, implementing care instructions as part of your branding can be a value addition to your products. Custom garment printing offers a personal touch, and accompanying care instructions can demonstrate your brand’s commitment to quality and customer service. By prioritizing proper care, you contribute to a lasting impression, ensuring that customers will appreciate their designs long after their purchase.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is an innovative method that transfers designs onto fabric using specially coated films. The process involves printing an image onto DTF film, applying adhesive powder, and then heat pressing the film onto the garment. This technique is known for producing vibrant colors and durable prints on a variety of fabrics.

What materials are used in DTF transfers?

DTF transfers primarily use DTF film, water-based inks specifically formulated for DTF printing, and DTF adhesive powder. Each of these materials is crucial for achieving high-quality, long-lasting designs that adhere well to fabrics.

How do I select the right DTF film for my designs?

Choosing the right DTF film is essential for successful transfers. Look for high-quality films that can hold ink effectively and produce vibrant designs. It’s beneficial to test various films to find one that works best with your specific printer and inks.

What are the best practices for heat pressing DTF transfers?

When heat pressing DTF transfers, it’s best to set your heat press at around 325°F for 15-20 seconds, adjusting as necessary for different fabric types. Ensure proper pressure and allow the transfer to cool before peeling off the film to achieve optimal adhesion.

How can I improve the adhesion of my DTF transfers?

To enhance adhesion, make sure to sprinkle adhesive powder evenly over the wet ink on the DTF film before heat pressing. Additionally, using the correct temperature and pressure during the heat press process is crucial for ensuring a successful transfer.

What care instructions should I provide for garments printed with DTF transfers?

To maintain the quality of DTF transfer prints, recommend washing garments in cold water and avoiding direct sunlight when drying. Providing clear care instructions enhances customer satisfaction and prolongs the life of the designs.

| Tip | Key Points |

|---|---|

| 1. Select the Right Film | Use high-quality DTF film to achieve vibrant colors. Experiment with different options for best results. |

| 2. Use Proper Ink Configuration | Choose water-based inks to enhance color vibrancy and avoid printer clogging. |

| 3. Optimize Printer Settings | Adjust settings based on ink and film type to ensure clear prints. |

| 4. Application of Adhesive Powder | Evenly apply adhesive powder to wet ink for proper adhesion during heat pressing. |

| 5. Fine-Tuning Heat Press Settings | Heat press at around 325°F for 15-20 seconds, consulting specific material guidelines. |

| 6. Cooling Time | Allow transfers to cool completely before peeling off film to avoid malfunctions. |

| 7. Choosing Appropriate Fabrics | Confirm adherence and color accuracy on chosen fabrics through test runs. |

| 8. Post-Press Treatment | Apply post-press heat treatment for added durability and polished finishes. |

| 9. Care Instructions | Provide washing and drying instructions to maintain design quality over time. |

| 10. Continuous Learning | Engage with DTF communities to stay updated on trends and techniques. |

Summary

DTF Transfers offer a unique opportunity to elevate your design projects, enabling you to create eye-catching, long-lasting designs on a variety of fabrics. By following these 10 expert tips, you can enhance your technique, ensuring that every transfer you complete not only looks great but withstands the test of time. From selecting the right film to optimizing your heat press settings, attention to detail is paramount in achieving stunning results. Stay informed and continuously refine your skills to remain competitive in the ever-evolving world of DTF printing. Happy printing!