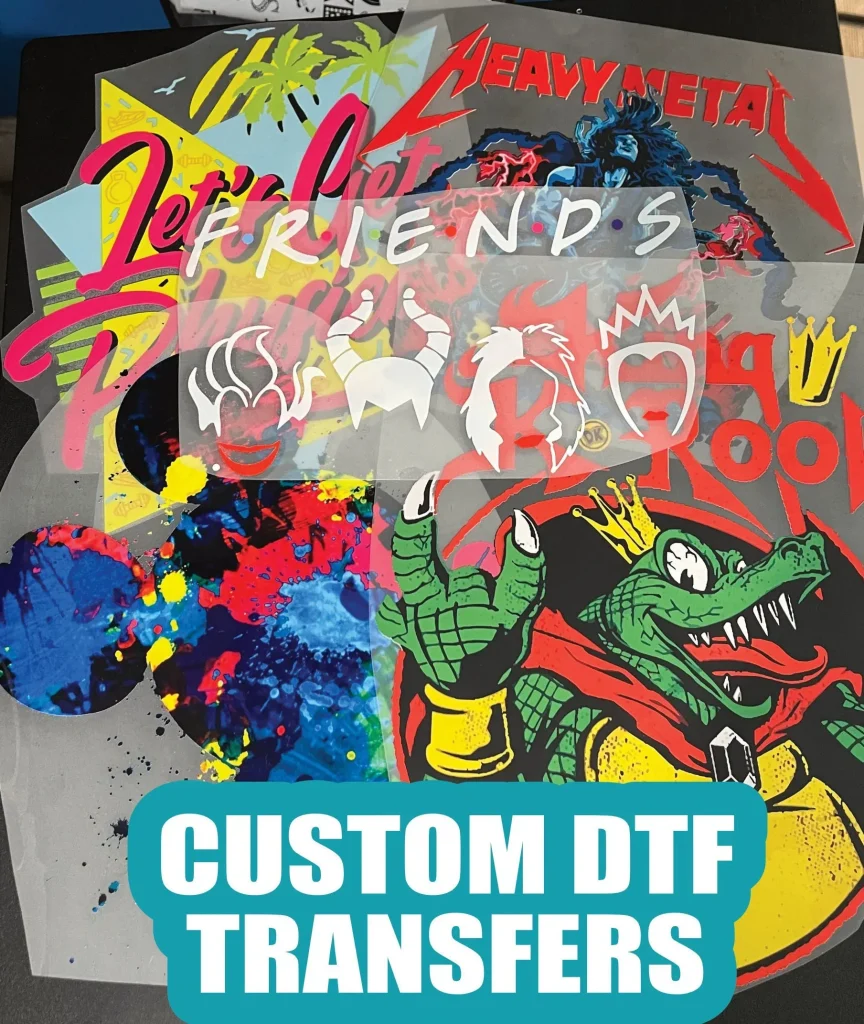

In the evolving landscape of textile printing, DTF transfers have emerged as a game-changing technique loved by both beginners and experts. Short for Direct to Film transfers, this innovative method allows enthusiasts to transfer detailed designs onto a wide range of fabrics with ease. Whether you aim to personalize clothing items or expand your artistic repertoire, understanding the DTF transfer process can significantly enhance your skills. Our beginner’s guide to DTF printing covers everything from essential DTF printing equipment to the intricacies of applying your first transfer. Get ready to unlock a world of creative possibilities as we delve into the essential steps and tips for successfully utilizing DTF transfers.

Direct to Film printing, often referred to simply as DTF, represents an exciting advancement in garment decoration techniques. This approach utilizes specialized transfer films to bring your designs to life on fabric, ideal for custom creations and small scale business ventures. If you’re curious about how to use DTF transfers or what equipment you need to get started, this guide will clarify the entire DTF transfer process. Delving into this beginner’s guide to DTF printing will equip you with the knowledge to create stunning prints that stand out. Let’s explore the essential methods and tools that make DTF a popular choice for many in the crafting world.

Introduction to DTF Transfers: What You Need to Know

Direct to Film (DTF) transfers are revolutionizing the way designs are applied to fabrics. With its straightforward process and impressive results, it has become a preferred choice for both beginners and experienced textile artists. Understanding the basics of DTF transfers is crucial as it enables you to harness their potential effectively. Knowing how to use DTF transfers will empower you to explore your creativity with vibrant designs that stand the test of time.

The DTF transfer process is not just about putting ink on fabric; it’s about transforming your ideas into reality. It allows for intricate details and colorful prints that were once difficult to achieve with traditional methods. Therefore, getting familiar with DTF printing equipment and techniques can provide a solid foundation for your creative projects. As you delve deeper, you’ll discover how fulfilling it is to master DTF transfers.

Understanding the DTF Printing Process

At the heart of DTF printing lies a unique methodology that simplifies the transfer of designs onto fabric. This process involves printing your design onto a specialized transfer film, which is then heat-pressed onto your substrate. Ensuring you have the right DTF printing equipment is fundamental for a successful print. The DTF inks used are specifically formulated to bond well with the film and fabric, guaranteeing vibrant and durable results.

Besides selecting the right printer, it’s essential to have the appropriate adhesive powder for ensuring that your design adheres seamlessly to the fabric. The application process might seem meticulous, but mastering each step from printing to heat setting will lead you to produce high-quality prints consistently. As you experiment with different techniques, understanding the nuances of the DTF transfer process will set you apart in your printing endeavors.

Essential Equipment for Successful DTF Transfers

Having the right DTF printing equipment is crucial for achieving optimal results. The requirements include a compatible printer, specialized transfer film, adhesive powder, and a reliable heat press. Investing in quality equipment ensures the integrity of your prints and can save time and effort in the long run. A dedicated inkjet printer designed for DTF inks is vital for ensuring color accuracy and print quality.

Moreover, utilizing design software such as Adobe Illustrator or CorelDRAW allows you to create stunning graphics tailored to your desired outcome. The synergy between quality equipment and effective design software is essential for producing professional-grade DTF transfers. As you equip yourself with the right tools, the possibilities for personalization through DTF printing expand significantly.

Step-by-Step Guide to Applying DTF Transfers

The DTF transfer process can be broken down into a simple step-by-step guide that makes it approachable for beginners. Start your journey by focusing on design creation – this step often sets the tone for the entire project. Remember to mirror your design before printing; failing to do so can result in a final product that doesn’t align correctly on the fabric.

After printing your design onto the transfer film, applying adhesive powder while the ink is still wet is critical for ensuring a strong bond once heat is applied. Following the careful preparation of your prints, heat setting is your next crucial step. Proper timing and temperature will help cure the powder and ensure that your design adheres effectively to the fabric during the final transfer application.

Tips and Tricks for DTF Transfer Success

As you refine your DTF transfer skills, incorporating tips and tricks can make a significant difference in your final product. One handy tip is to always perform test prints on scrap fabrics; this minimizes waste and helps ensure that you achieve the desired results when it’s time to print on your final garment. Each fabric behaves differently, and testing allows you to adjust your methods accordingly.

Additionally, maintaining your DTF printing equipment is crucial for consistency and quality. Routine maintenance, such as cleaning the printer and heat press, keeps your workspace operating smoothly and can greatly prolong the life of your equipment. Investing in high-quality materials also pays off in producing print durability, enhancing the longevity of your creations.

Maximizing Creativity with DTF Printing

DTF transfers unleash a world of creative possibilities. Embracing this method of printing can expand your artistic capabilities and allow you to produce unique, custom designs for personal use or even small business ventures. The ability to create intricate patterns and professionally finish garments means you can dive deeper into your creative pursuits with confidence.

Whether you’re designing apparel for family gatherings, gifts, or starting your own crafting business, the mastery of DTF printing equips you with the skills necessary to turn ideas into tangible products. Engaging with community forums can also provide insights and techniques from fellow enthusiasts, fostering a collaborative environment for creative growth. With DTF printing, the sky truly is the limit.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves printing images onto a special transfer film using DTF inks, then applying an adhesive powder while the ink is still wet. After curing the print with heat, the film is placed on a garment using a heat press to transfer the design, resulting in vibrant prints that adhere well to various fabrics.

How do I use DTF transfers for textile printing?

To use DTF transfers, start by designing your image in graphic design software. Print the mirrored design onto transfer film, sprinkle adhesive powder over the wet ink, and heat set it. Finally, use a heat press to transfer the design onto your garment, ensuring you follow proper temperature and pressure guidelines.

What equipment do I need for successful DTF printing?

For successful DTF printing, you’ll need an inkjet printer compatible with DTF inks, special transfer film, adhesive powder, a heat press, and graphic design software. This equipment is essential for achieving high-quality and durable prints.

What are the benefits of using DTF transfers compared to other methods?

DTF transfers offer several benefits, including vibrant colors, durability with proper care, and versatility across different fabrics. Unlike traditional methods, DTF allows intricate designs and fine details, making it ideal for custom apparel or small business ventures.

Can beginners easily learn how to use DTF transfers?

Yes, beginners can quickly learn how to use DTF transfers by following a step-by-step guide. With the right equipment and practice, mastering DTF printing techniques can enhance your crafting skills and lead to impressive results.

What tips can I use to ensure the best results with DTF printing equipment?

To ensure the best results with DTF printing equipment, always perform test prints on scrap materials, maintain your printer and heat press regularly, use high-quality inks and films, and store unused transfers properly. These practices will optimize your print quality and longevity.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A method for printing images onto transfer film, which can be applied to garments with heat press, suitable for various materials. |

| Equipment Needed | 1. Inkjet printer compatible with DTF inks 2. Transfer film 3. Adhesive powder 4. Heat press 5. Graphic design software |

| Step 1: Design Creation | Create your design using software and mirror it before printing. |

| Step 2: Printing the Design | Print the mirrored design onto the transfer film using optimized printer settings. |

| Step 3: Applying Adhesive Powder | Sprinkle adhesive powder on the wet ink, ensuring even coverage. |

| Step 4: Heat Setting the Print | Cure the print using an oven or heat press to secure the adhesive. |

| Step 5: Transferring the Design | Place the film on the fabric and apply heat and pressure. |

| Step 6: Peeling and Finishing | Carefully peel off the film after cooling and touch up edges as needed. |

| Tips for Success | 1. Test prints on scrap fabric. 2. Maintain your printer and heat press. 3. Store unused transfers properly. 4. Use quality materials. |

Summary

DTF transfers are a versatile and increasingly popular method in the textile printing realm, offering beginners and professionals alike a pathway to create intricate fabric designs with ease. By understanding the fundamentals of DTF transfers—including the necessary equipment, step-by-step printing process, and essential tips for success—users can unlock a plethora of artistic possibilities. As this guide illustrates, mastering DTF transfers not only enhances your craftsmanship but also equips you with the skills to produce stunning, durable prints suitable for personal projects or small business ventures. Delve into the world of DTF printing today and let your creativity flourish.