DTF transfers, or Direct to Film transfers, are revolutionizing the textile printing industry with their impressive versatility and quality. Unlike traditional methods such as screen printing and Direct to Garment (DTG) printing, DTF offers a unique approach by utilizing a special transfer film that allows for vibrant designs on various fabrics. With the advantages of DTF printing becoming increasingly recognized, this method is noted for its cost-effectiveness and exceptional print durability, making it a standout choice among the best printing methods available today. In this guide, we will explore how DTF transfers compare to other printing techniques, examining the key differences in print quality, setup costs, and production capabilities. As businesses seek out efficient solutions, understanding the DTF printing advantages can help in determining the ideal method for your needs.

In the realm of garment printing, the emergence of Direct to Film (DTF) transfers has sparked interest and innovation. This technique utilizes a transfer medium that enables high-quality prints on various textiles, allowing for a broad range of customization options. When considering alternatives, one might also encounter terms like DTF printing, which highlights its effective application across different surfaces. As we delve into a comparison of DTF with other popular methods such as Direct to Garment (DTG) and screen printing, it becomes essential to recognize the strengths and trade-offs of each printing option, especially regarding durability and production efficiency.

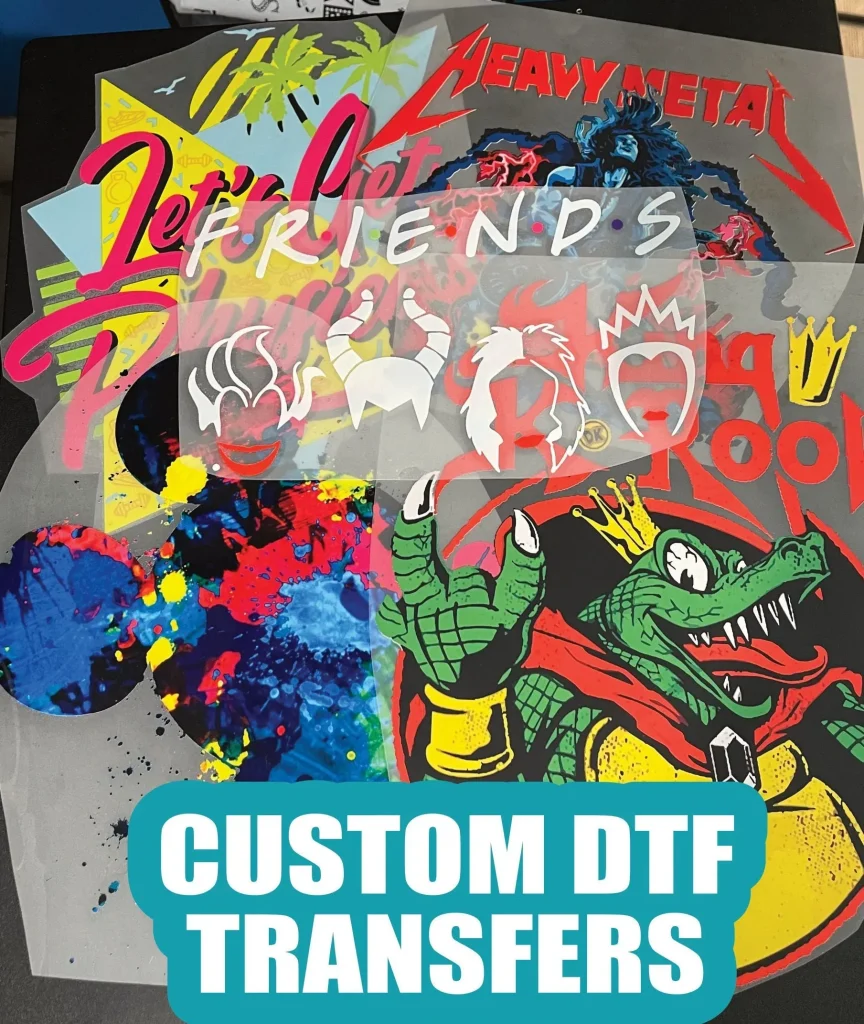

What are DTF Transfers and How Do They Work?

DTF transfers, or Direct to Film transfers, represent an innovative textile printing method that has gained traction in the garment industry due to its compelling advantages. The process starts with printing designs onto a special film that is designed to adhere well to various fabrics. Following this, heat is applied, which activates the adhesive on the film, allowing the design to bond securely to the garment. This method is noteworthy because it allows for high-quality prints that can be cost-effectively produced in both small and large batches.

In contrast to more traditional methods like screen printing and DTG (Direct to Garment), DTF transfers offer flexibility across a variety of textiles, including cotton, polyester, and blends. This broad compatibility opens up numerous possibilities for businesses looking to diversify their product offerings. The ease of application and transfer helps streamline production, making it an attractive option for both startups and established businesses aiming to enhance their printing capabilities.

Furthermore, DTF technology has made it more accessible for small print shops to achieve professionally curated designs without the need for extensive setups or expensive machinery. The evolution of DTF has significantly lowered the barrier to entry in the custom apparel market, empowering entrepreneurs to enter the industry with confidence.

Overall, the DTF transfer process combines simplicity with high-quality output, demonstrating its potential as a game-changer in textile production.

DTF Printing Advantages: Why Choose DTF?

The advantages of DTF printing are substantial and make it an appealing option over other printing techniques. One primary benefit is the vibrant colors produced by DTF printers. They utilize specially formulated inks designed to deliver stunning visuals that capture attention. This quality is particularly important when producing promotional materials or custom apparel where design matters significantly. Businesses can meet client expectations and stand out in a competitive market with the bright, vivid colors DTF can achieve.

Furthermore, durability stands out as another impressive feature of DTF printing. Prints created through this method are known to resist fading, cracking, and peeling, even after multiple washes. Consumers increasingly expect longevity from printed apparel, which is why the wash resistance of DTF is a critical selling point. This durability not only enhances customer satisfaction but also reduces the rate of returns and complaints, providing businesses with a solid reputation for quality.

Comparing DTF to DTG: Key Differences Explained

When comparing DTF (Direct to Film) printing to DTG (Direct to Garment) printing, it’s essential to consider the unique characteristics and advantages of each method. DTG is known for its ability to print complex designs with photographic quality directly onto the garment. However, this method can become cost-prohibitive for larger orders due to the significant setup costs associated with each unique design. In contrast, DTF excels in flexibility, enabling the production of high-quality prints across various materials without the extensive setup associated with DTG.

Moreover, while DTG’s advantage lies in its high resolution and detail, DTF’s versatility allows businesses to address a broader range of customer needs. Companies that require prints on diverse fabric types or smaller runs of multiple designs often find DTF to be the more economical and practical option, ensuring that they can serve various clientele effectively.

DTF vs. Screen Printing: Which is More Cost-Effective?

Screen printing is a traditional method that has dominated the industry for years, primarily due to its cost-effectiveness for large volume orders. However, when comparing screen printing to DTF, particularly for small to medium-sized orders, DTF frequently proves to be more economical. Screen printing involves considerable setup and teardown time, and it tends to be less versatile compared to DTF, which can seamlessly adapt to various material types without incurring additional costs.

DTF printing mitigates many of the common barriers associated with screen printing. With DTF, businesses can efficiently manage smaller orders without sacrificing print quality. This operational efficiency not only maximizes profit margins but also allows for rapid turnaround times, essential for modern consumer expectations.

Understanding DTF Print Quality: Performance Insights

The print quality of DTF transfers is highly regarded in the textile industry, owing to the advanced technology used in the printing process. DTF inks are designed to fuse with the fabric during the transfer process, resulting in vibrant, bold designs that maintain their integrity over time. When compared to some older methods, such as traditional screen printing, the color saturation and detail achieved with DTF are often superior.

Moreover, DTF’s exceptional print quality extends to a wide spectrum of fabrics, including dark and light textiles. This flexibility ensures that businesses can produce high-end products that appeal to varying market segments. Ultimately, the ability to deliver high-quality products consistently positions DTF transfers as a compelling choice for any print business looking to optimize its offerings.

Choosing the Best Printing Method for Your Needs

Selecting the ideal printing method among DTF, DTG, and screen printing ultimately hinges on several specific factors. Businesses must assess their unique requirements, including material types, order volumes, and design complexities. For instance, if your needs frequently fluctuate between different materials, DTF printing stands out for its adaptability, allowing businesses to switch between fabric types effortlessly.

Furthermore, the complexity of the designs being produced plays a crucial role in this decision-making process. While DTG may be the primary choice for highly intricate designs, DTF often strikes a balance between quality and efficiency for more straightforward graphics. Understanding these elements will help businesses capitalize on the strengths of each method, ensuring they select a printing solution that aligns with their operational goals and budgetary considerations.

Frequently Asked Questions

What are the advantages of DTF printing over traditional methods?

DTF printing offers several advantages, including versatility on different fabric types, vibrant colors that attract attention, excellent durability against fading and peeling, and cost-effectiveness, especially for smaller production runs compared to traditional methods like DTG or screen printing.

How does DTF printing compare to DTG printing?

DTF printing is often more cost-effective than DTG, particularly for smaller runs and designs that don’t require the photographic quality that DTG excels at. While DTG is best for intricate designs, DTF provides quicker setup times and lower operational costs.

Is DTF printing a better option than screen printing for small orders?

Yes, DTF printing is generally a better option for small orders compared to screen printing, which has higher setup costs and time requirements. DTF allows for flexibility and affordability in producing high-quality prints with minimal overhead.

What quality of prints can I expect with DTF transfers?

DTF print quality is known for its vibrant colors and durability, making prints resistant to fading and wear. This allows designs to maintain their visual appeal over time, a significant advantage over some traditional printing methods.

Can DTF transfers be used on all types of fabrics?

Yes, one of the key benefits of DTF transfers is their versatility; they can be applied to a wide range of materials, including cotton, polyester, and blends, allowing businesses to cater to diverse customer needs.

What makes DTF printing a cost-effective choice for startups?

DTF printing is cost-effective for startups as it incurs lower initial setup costs and allows for efficient bulk production. This means new businesses can produce high-quality prints without substantial financial investment, providing a competitive edge in the market.

| Key Points | DTF Transfers | Comparison with Other Methods |

|---|---|---|

| Description | Prints designs onto transfer film, then transfers to fabric using heat and pressure. | – DTG: Direct application to garments, unique textures. – Screen Printing: Cost-effective for high-volume orders. |

| Versatility | Can print on various materials including cotton and polyester, making it suitable for diverse products. | – DTG: Best for complex designs. – Screen Printing: Less flexible for small runs. |

| Vibrant Colors | Uses high-quality inks for vivid outputs that grab attention. | – DTG: Excellent for intricate designs, higher costs. – Screen Printing: Durable and vibrant, but less flexible. |

| Durability | Strong wash resistance; colors do not fade or peel. | – DTG: Fades on dark fabrics unless pre-treated. – Screen Printing: Very durable. |

| Cost-Effectiveness | Lower setup costs especially beneficial for small to medium runs. | – Screen Printing: Better for high-volume orders, setup costs can be high. – Sublimation: Limited applications and not cost-effective for dark garments. |

Summary

DTF Transfers have emerged as a competitive option in textile printing, appealing to businesses looking for cost-effective and high-quality solutions. Their ability to print on multiple materials, combined with durable and vibrant outputs, positions DTF printing as not just a trend but a lasting choice for numerous applications. As technology progresses and eco-friendly options become more available, DTF Transfers are set to remain at the forefront of the garment printing industry, offering versatility and efficiency to meet diverse market needs.