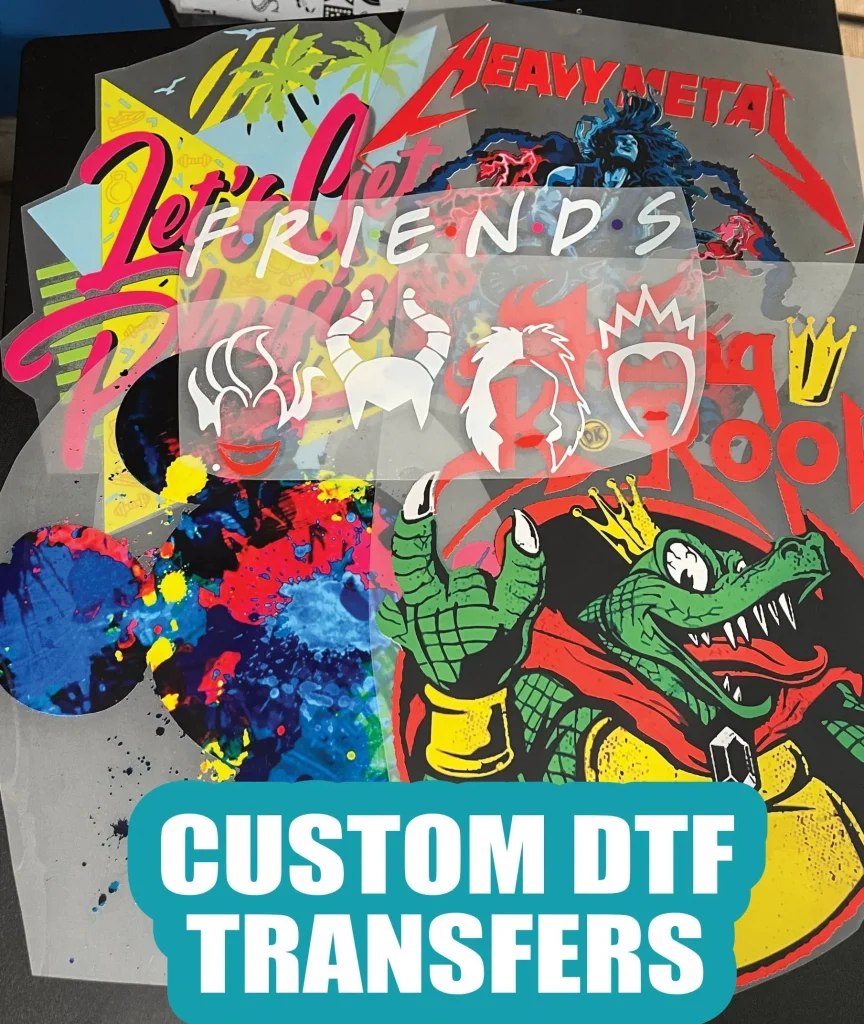

DTF Transfers, or Direct to Film Transfers, have taken the custom printing world by storm, offering a cutting-edge solution for creating vibrant designs on various textiles. This innovative DTF printing process allows for intricate detailing, making it an excellent choice for custom apparel printing and more. Whether you’re passionate about fashion design or simply looking to personalize everyday wear, DTF Transfers provide a versatile and efficient printing method. With numerous benefits such as durability and cost-effectiveness, it’s no wonder that businesses and hobbyists alike are turning to this technique. In this guide, we’ll delve deeper into the fascinating world of DTF Transfers, uncovering essential information and tips to get you started on your creative journey.

The advancement of printing technologies has introduced various alternatives, among which Direct-to-Film method stands out as a remarkable option for textile customization. Often referred to as DTF printing, this technique allows artists and entrepreneurs to transfer their designs seamlessly onto fabric surfaces. The appeal of this process lies in its ability to achieve exceptional vibrancy and detail, making it a favorite in the realm of custom apparel. Whether producing promotional merchandise or personal gifts, the benefits of utilizing this modern printing technique are extensive, providing an efficient pathway to realize unique and colorful creations. This introduction to the DTF Transfers guide will equip you with knowledge and skills needed to leverage this powerful printing process.

Understanding the DTF Printing Process

The DTF printing process is a meticulous method that combines various advanced printing technologies to create stunning results. It begins with high-resolution designs being printed onto a special PET film using specialized DTF printers. These printers utilize unique inks formulated specifically for DTF printing, ensuring that images are rich in color and detail. Once printed, a powdered adhesive is applied to the wet ink to guarantee a strong bond. This essential adhesive application step differentiates DTF transfers from other printing methods, enabling designers to achieve vibrant prints regardless of the fabric’s color.

After the adhesive is sprinkled onto the printed film, the design is cured using a heat source, allowing the adhesive to bond firmly with the ink. The final step of the DTF printing process involves heat pressing the film onto the chosen textile, where heat and pressure work in harmony to create a seamless transfer. This unique combination of technology and technique not only simplifies the process but also allows for the production of high-quality prints that stand the test of time.

Key Advantages of DTF Transfers for Custom Apparel

DTF Transfers offer several significant benefits for custom apparel printing that make them an appealing choice for businesses and hobbyists alike. One of the most notable advantages is the vibrant color reproduction on various textiles, including cotton and polyester. Unlike traditional methods such as screen printing, DTF provides a wider color spectrum, allowing designers to push creative boundaries and produce eye-catching designs that truly stand out. This capability is crucial for brands looking to make a bold statement in the competitive fashion industry.

Another key advantage of DTF transfers is their versatility in application. Whether for creating sportswear, casual clothing, or promotional merchandise, DTF can be adapted to meet the diverse needs of clients. This flexibility also includes the ability to produce small batches economically, catering to niche markets and personalized orders without the burden of large minimums often required by other printing processes. DTF technology not only enhances creativity but also promotes efficiency and cost-effectiveness in apparel production.

Durability and Longevity of DTF Prints

When considering printing options, the durability and longevity of the finished product are paramount, especially in the world of apparel. DTF Transfers excel in this aspect, as they yield prints that can endure multiple washes without fading or cracking. This resilience is particularly essential for businesses that prioritize quality and seek to ensure customer satisfaction. The strong bond created between the fabric and the printed design through the DTF process means that customers can enjoy their apparel for longer, benefiting both brand reputation and buyer loyalty.

Furthermore, the robust nature of DTF prints makes them suitable for various applications beyond apparel, including promotional items and personalized gifts. Customers can rest assured that their custom designs will maintain their vibrancy and integrity over time, making DTF a smart choice for businesses looking to establish trust and a positive impression with their clients.

Applications of DTF Transfers in Various Industries

The versatility of DTF Transfers has made them an invaluable tool across multiple industries, particularly in fashion, promotional merchandise, and personalized gifts. In the fashion world, it permits designers to create unique and intricate apparel pieces that cater to a diverse clientele. The ability to incorporate complex colors and patterns has transformed traditional fashion printing, allowing more creativity and innovation to flourish. This simplicity in adapting designs instantly showcases why many designers are increasingly embracing DTF printing.

In the realm of promotional items, DTF Transfers have significant implications for business branding. By allowing companies to produce high-quality custom items such as t-shirts, bags, and hats without the need for extensive setup times or minimum order quantities, DTF enables businesses to effectively connect with their target audience. Furthermore, the personalization potential of DTF printing fosters stronger connections between brands and consumers, offering tailored merchandise that resonates with individual preferences.

Getting Started with DTF Transfers: Essential Equipment

As with any printing method, having the right equipment is fundamental to achieving high-quality DTF Transfers. Starting with a reputable DTF printer is critical; these machines are engineered specifically for the DTF printing process and typically offer a range of features that enhance usability and output quality. In addition to the printer, selecting high-quality inks tailored for DTF applications will significantly influence the vibrancy and longevity of your prints.

Another vital component is investing in a reliable heat press. The consistency and effectiveness of the heat press are crucial to ensuring proper adhesive bonding during the transfer process. Additionally, sourcing high-quality PET films compatible with your equipment will help maintain accuracy and print quality. By focusing on these essential tools, anyone interested in DTF Transfers can set themselves up for success and produce professional-grade prints that align with customer expectations.

Tips for Mastering the DTF Printing Process

To truly master the DTF printing process, practice and experimentation are vital. Start by familiarizing yourself with each step, from printing through to heat pressing, and take note of how different settings and materials affect the final print. Regularly testing various designs on different fabrics will help you understand the nuances of DTF Transfers better, allowing you to refine your technique over time. This hands-on approach not only builds confidence but is crucial for troubleshooting any issues that arise.

Additionally, engage with online communities and resources dedicated to DTF Transfers. Many enthusiasts and professionals share tips, techniques, and troubleshooting advice based on their experiences. Collaborating with others does not just enhance your knowledge of the DTF printing process, but it can also inspire creativity, pushing you to explore new design ideas and applications.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film Transfers, are a modern printing method that allows for the transfer of vibrant images from a film directly onto textiles. The process involves three key steps: printing a design onto a PET film using specialized DTF printers, applying powdered adhesive to the wet ink, and finally heat pressing the film onto the fabric. This technique provides detailed prints with strong adherence to various materials.

What are the benefits of using the DTF printing process for custom apparel?

The DTF printing process offers numerous benefits for custom apparel including vibrant colors, versatility across different fabric types, cost-effectiveness for small runs, durable prints that withstand washing, and ease of use which makes it beginner-friendly. These factors make DTF Transfers an attractive choice for anyone involved in custom apparel printing.

How does DTF Transfers compare to traditional screen printing?

DTF Transfers offer several advantages over traditional screen printing, including the ability to print small batches without minimum order requirements, a wider color gamut for more vibrant designs, and greater versatility across different materials. Additionally, DTF Transfers produce long-lasting prints and can often reduce production time compared to conventional methods.

What types of fabrics can DTF Transfers be applied to?

DTF Transfers can be applied to a wide variety of fabrics, including cotton, polyester, and their blends. This versatility makes them suitable for various applications such as T-shirts, sportswear, fashion items, and promotional merchandise, allowing for a wide range of creative possibilities in custom apparel printing.

What equipment is needed to start using DTF Transfers?

To get started with DTF Transfers, you will need quality equipment including a DTF printer that uses specific inks for vibrant colors, high-quality PET films for transfer, a powdered adhesive for effective bonding, and a reliable heat press to ensure adequate heat and pressure for the transfer process. Investing in the right tools can significantly improve your printing results.

Can DTF Transfers be used for personalized gifts and promotional items?

Yes, DTF Transfers are ideal for creating personalized gifts and promotional items. The ability to produce intricate designs and small batch runs makes it easy to customize products such as T-shirts, bags, and hats. This flexibility allows businesses and individuals to offer unique designs that reflect personal preferences and branding needs.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | A printing technique that transfers images from film to textile, allowing for versatile and detailed designs. |

| Process Steps | Includes Printing (using specialized DTF printers), Adhesive Application (using powdered adhesive), and Heat Pressing (to transfer design onto fabric). |

| Benefits | Includes vibrant colors, versatility across materials, cost-effectiveness for small orders, durability of prints, and ease of use. |

| Applications | Used in fashion, promotional items, and personalized gifts due to the ability to create detailed and colorful designs. |

| Getting Started Tips | Invest in quality DTF equipment, use compatible films, practice to master the process, and effectively market your products. |

Summary

DTF Transfers have become a game-changer in the printing industry by providing an efficient and high-quality method for transferring designs onto various textiles. This advanced technique is not only ideal for creating vibrant and intricate prints but also supports a wide range of materials, making it a popular choice among both hobbyists and professionals. As more businesses seek to offer personalized and custom products, understanding and utilizing DTF Transfers can significantly enhance creativity and adaptability in today’s competitive market. Whether you’re embarking on a new venture or expanding your printing capabilities, DTF Transfers can truly elevate your offerings.