DTF Transfers, or Direct to Film transfers, are quickly becoming a favorite technique in the realm of custom fabric printing. This innovative method allows users to create vibrant and detailed designs that adhere seamlessly to a variety of textiles. One of the key DTF printing advantages is its versatility, enabling high-quality applications on fabrics that traditional methods might struggle with. As we delve into the differences with other printing methods like screen printing and heat transfer vinyl, we’ll uncover the essential pros and cons that define each option, including valuable insights into sublimation printing benefits. Whether you’re an artist or a business seeking to expand your product offerings, understanding DTF transfers is crucial to making an informed choice among custom fabric printing methods.

When exploring options for fabric design, Direct to Film (DTF) printing presents a compelling choice that distinguishes itself in the competitive landscape of textile printing solutions. This technique, akin to alternative methods such as screen printing and heat transfer vinyl, showcases unique characteristics that attract crafters and small businesses alike. The ease of applying intricate designs coupled with the impressive durability of DTF applications positions it as a notable contender among custom printing techniques. In this discussion, we will explore how DTF compares to other processes, including the advantages of sublimation printing and the limitations of heat transfer vinyl, providing a comprehensive look at printing options for diverse fabric types.

Understanding DTF Transfers and Their Unique Properties

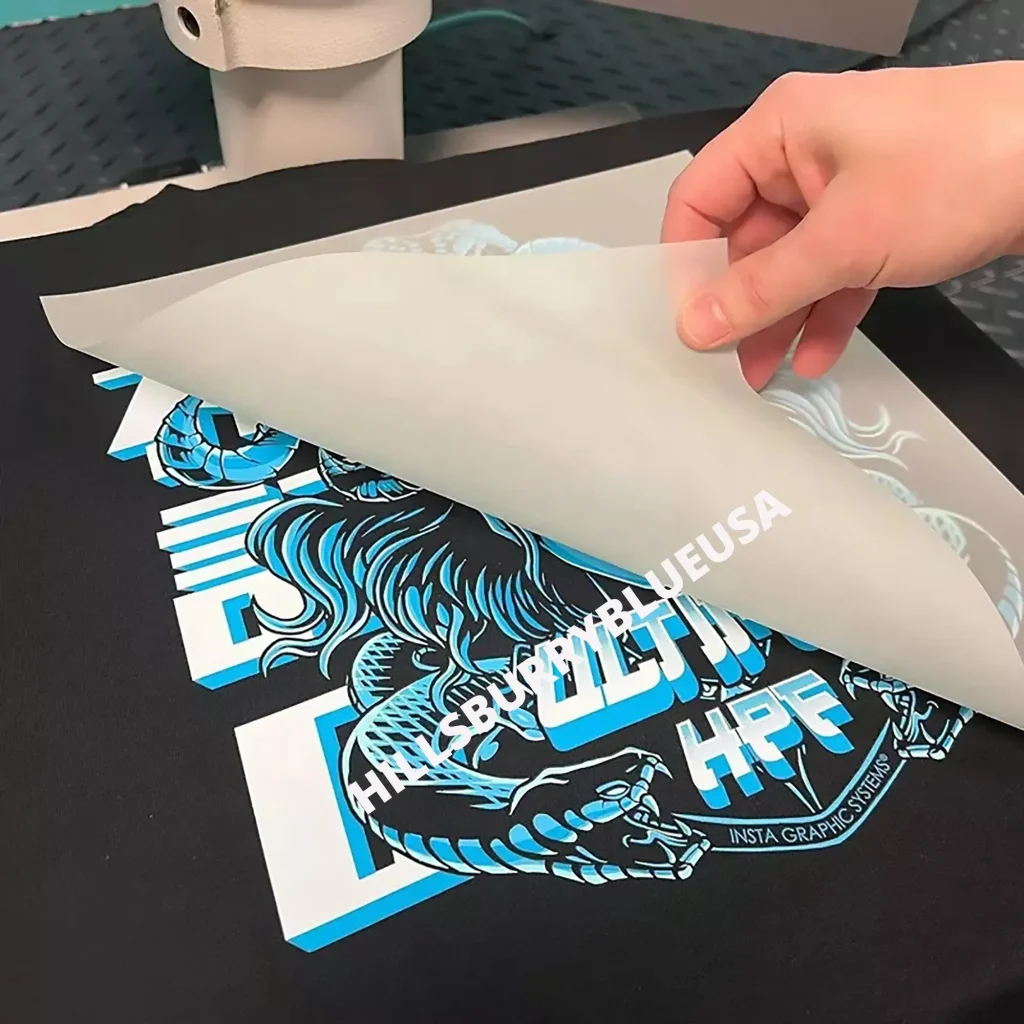

Direct to Film (DTF) transfers represent a pivotal advancement in the realm of custom fabric printing. This technique employs high-quality inks printed onto a specially developed film, which is then transferred onto the desired fabric using a heat press. This process is particularly noteworthy due to its ability to produce vibrant graphics that maintain their integrity and softness even after multiple washes. The versatility of DTF is one of its most appealing attributes, as it works seamlessly across various fabric types, including cotton, polyester, and blends, catering to a wide range of printing needs.

Apart from its impressive fidelity in color reproduction, DTF transfers are designed to ensure durability. Unlike other methods like heat transfer vinyl (HTV) which may fade or peel over time, DTF prints become part of the fabric, providing a long-lasting solution for custom designs. Moreover, the relatively low setup costs and minimal waste make it an attractive option for both small enterprises and personal projects requiring high-quality output. In contrast to traditional printing methods, DTF facilitates easier sampling and rapid prototyping, which is crucial for custom fabric printing.

Advantages of DTF Printing: Why Choose This Method?

One of the primary advantages of DTF printing is its exceptional print quality that rivals sublimation printing. DTF can produce vibrant colors and intricate designs that adhere seamlessly to different fabric types. This versatility allows artists, designers, and businesses to showcase their creativity without being restricted by fabric choices. Additionally, the durability of the prints is noteworthy; DTF transfers resist fading and cracking, ensuring that your designs remain vibrant and intact over time, even with repeated washes and wear.

Moreover, DTF printing offers a more straightforward and efficient setup process compared to methods like screen printing, which often requires numerous screens for multi-colored designs. With DTF, a single transfer can incorporate multiple colors and complex gradients, significantly streamlining the design process. This efficiency translates not only to time savings but also to cost-effectiveness, especially for smaller runs where traditional methods may become prohibitively expensive.

Screen Printing vs DTF: Pros and Cons Explained

When comparing screen printing with DTF, several factors come into play. Screen printing has long been a favorite for mass production due to its economical nature with large runs, but it presents challenges when it comes to intricate designs with numerous colors. For detailed artwork, several screens must be set up, which can inflate costs and extend lead times. In contrast, DTF’s single-transfer capability allows for complex designs to be produced swiftly and without excessive materials or time commitments.

On the downside, while screen printing produces exceptionally sturdy designs, it falls short when it comes to fabric compatibility. Screen printing primarily adheres to cotton fabrics, while DTF boasts versatility across a range of textile materials. Users opting for DTF can explore more creative avenues with various substrates, including blends and synthetic materials. Therefore, while screen printing may be cost-effective for bulk orders, DTF printing offers quality and versatility that caters to businesses seek unique offerings and custom projects.

Heat Transfer Vinyl: Exploring Pros and Cons

Heat transfer vinyl (HTV) has increasingly become popular among hobbyists and small businesses for its user-friendly application. However, its durability raises concerns when compared to DTF transfers. HTV prints can sometimes peel or fade after extensive wear, which can be a drawback for products intended for commercial sale. In contrast, DTF transfers are known for maintaining their appearance over time, appealing to customers who prioritize long-lasting artworks.

Another downside of HTV is its limited color blending capabilities. Unlike DTF, where designers can achieve gradients and intricate details, HTV typically relies on solid color cutouts, restricting creative expressions. This limitation can hinder the potential for unique, eye-catching designs that stand out in today’s competitive marketplace. Therefore, for those looking at long-term investments in quality custom fabric printing techniques, DTF presents a more reliable and versatile option.

Sublimation Printing Benefits: A Comparative Analysis

Sublimation printing is typically heralded for its ability to produce stunning, high-resolution designs that infuse color directly into the fabric. This process offers the advantage of no-feel printing and an impressive longevity as it embeds colors permanently. However, there are significant limitations as this method primarily works on polyester fabrics, leaving users with fewer options for fabric types compared to DTF transfers. DTF’s compatibility extends beyond polyester, allowing for the creation of designs on natural fibers and blended textiles.

Additionally, the setup costs associated with sublimation can be daunting for newcomers. While the end results are often highly desirable, the initial investment in specific printers, inks, and equipment can be significant. On the other hand, DTF printing allows for more economical entry points without sacrificing quality, making it ideal for small businesses or individual entrepreneurs eager to explore various fabric printing options.

Making the Right Choice: Custom Fabric Printing Methods

Choosing the right printing method for custom fabric design involves a careful examination of specific needs, budgets, and fabric types. Each method, including DTF, sublimation, screen printing, and HTV, presents distinct advantages that cater to various scenarios. DTF stands out for its versatility and ability to maintain high-quality prints across diverse materials, helping designers to adapt to changing market demands.

As consumers increasingly seek personalized and unique fabric offerings, understanding the strengths and limitations of each printing technique becomes crucial. By considering factors such as cost-effectiveness, durability, ease of use, and the overall production process, businesses and hobbyists alike can make informed decisions that align with their creative visions and operational needs.

Frequently Asked Questions

What are the main DTF printing advantages for custom fabric projects?

DTF transfers offer several advantages for custom fabric projects, including versatility across various fabric types, high-quality and vibrant prints, and excellent durability. Unlike other methods, DTF can be used on cotton, polyester, and blends, allowing for stunning designs that remain soft to the touch. Additionally, DTF printing minimizes the risk of peeling or fading, making it a reliable choice for both small and large production runs.

How does DTF printing compare to screen printing for bulk orders?

When comparing DTF vs screen printing, DTF transfers stand out due to their ability to produce detailed, multi-colored designs without the limitations of color restrictions inherent in screen printing. While screen printing is more cost-effective for bulk orders, DTF offers flexibility in terms of design complexity and quality. With DTF, you can achieve finer details and more vibrant colors, making it an excellent alternative for custom merchandise.

What are the heat transfer vinyl pros and cons versus DTF printing?

When considering heat transfer vinyl (HTV) pros and cons compared to DTF printing, HTV is more accessible for beginners and ideal for small runs and personalized designs. However, DTF printing excels in durability and color vibrancy without the risk of peeling over time. HTV prints can fade or wear out quicker than DTF, making DTF a superior choice for long-lasting quality in fabric designs.

What are the benefits of sublimation printing compared to DTF transfers?

Sublimation printing benefits include vibrant, high-resolution designs that are embedded into the fabric, providing a seamless feel that DTF transfers don’t replicate. While sublimation is excellent for polyester fabrics, it has limitations regarding fabric compatibility. On the other hand, DTF transfers work on various fabric types, making them more versatile for different projects, especially for those who use cotton or blends.

Why should businesses consider DTF transfers for custom fabric printing?

Businesses should consider DTF transfers for custom fabric printing due to the method’s versatility, high-quality outputs, and durability. DTF allows for detailed and colorful designs that can cater to diverse fabric types, ideal for various merchandising needs. Its ability to maintain vibrancy and softness also ensures that the final products remain appealing to customers, setting a business apart from competitors using traditional methods.

What should I consider when choosing between DTF transfers and other custom fabric printing methods?

When choosing between DTF transfers and other custom fabric printing methods, consider factors such as fabric type, design complexity, production volume, and budget. DTF printing offers extensive fabric options and excellent quality, making it great for detailed designs. However, if you’re focused on bulk production, cost efficiency might lead you towards screen printing. Ultimately, the best choice will depend on your specific project requirements and goals.

| Printing Method | Pros | Cons |

|---|---|---|

| DTF Transfers | – Versatile on many fabrics – High print quality – Durable prints |

– Higher initial setup cost – Requires heat press |

| Sublimation Printing | – Vibrant colors – No feel printing |

– Limited to polyester fabrics – Costly setup |

| Screen Printing | – Cost-effective for bulk – Durable results |

– High setup costs – Color limitations |

| Heat Transfer Vinyl (HTV) | – Easy to use – Good for small runs |

– Durability issues – Limited color blending |

Summary

DTF transfers offer a compelling option for custom fabric printing, balancing versatility and print quality effectively. This innovative printing method stands out for its capability to adapt to a variety of fabrics while ensuring durability and vibrant output. As users increasingly seek customization in textile designs, DTF transfers provide an efficient solution suitable for both personal and commercial applications. Ultimately, understanding the strengths and weaknesses of DTF compared to traditional methods such as sublimation, screen printing, and HTV allows you to choose the best approach for your specific printing needs.