DTF Transfers, or Direct-to-Film transfers, are revolutionizing the custom printing landscape, offering a seamless and innovative solution for businesses aiming to deliver superior print quality. This cutting-edge technology not only enhances the efficiency of the printing process but also provides a cost-effective printing alternative that can cater to diverse customer needs. As consumer demands evolve towards sustainable printing practices, DTF transfers emerge as a compelling choice, reducing waste while ensuring vibrant, intricate designs can be replicated with ease. The rise of DTF printing technology signifies a shift toward accessible custom printing solutions that maintain high standards of excellence. Explore how DTF Transfers can transform your business and meet the growing expectations of today’s discerning consumers.

Direct-to-Film transfers represent a game-changing approach in the realm of garment printing, commonly referred to as DTF printing. This method employs advanced printing techniques to produce stunning designs that are easily transferred onto various fabrics, positioning itself as an attractive option for businesses focusing on custom print production. With the capability to produce high-quality prints that are both versatile and reliable, the DTF printing process opens the door to new possibilities for creative expression in the textile industry. By utilizing innovative technology, this form of custom printing not only enhances product offerings but also aligns with the trends of sustainability, providing companies with a competitive edge in an increasingly eco-conscious market. Embracing DTF techniques is indeed a strategic move for any business seeking to thrive in today’s diverse marketplace.

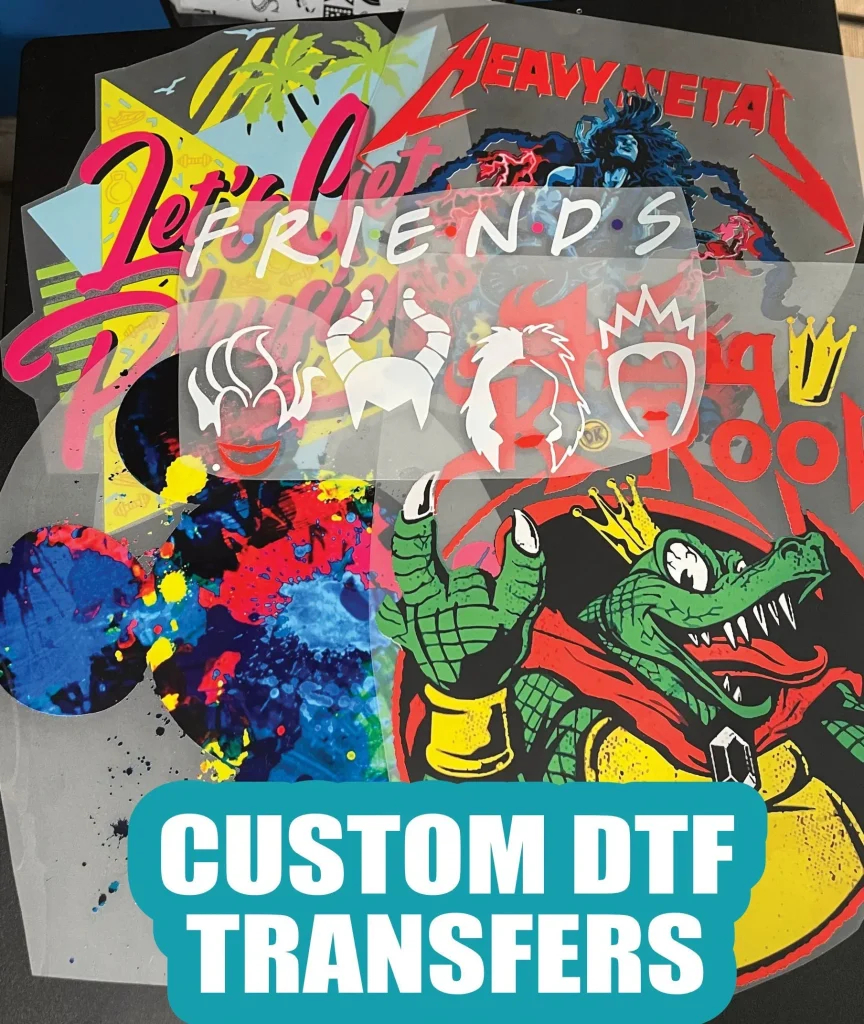

Understanding DTF Transfers: The Future of Custom Printing

DTF transfers stand at the forefront of the custom printing revolution, offering a blend of efficiency and print quality that traditional methods struggle to match. Gone are the days of cumbersome setup processes and high upfront costs, with Direct-to-Film technology simplifying how designs are transferred onto various materials. This innovative method replaces traditional screen printing’s complexity, enabling businesses of all sizes to embrace custom printing without the fear of significant initial investments.

As consumers increasingly demand unique and high-quality products, DTF transfers provide the solution with their vibrant color reproduction and ability to handle intricate designs. Businesses can now cater to ever-diversifying consumer tastes, from bulk orders to personalized items, positioning DTF transfers as not just a trend but a staple in the contemporary custom print landscape.

Advantages of DTF Transfers in Print Quality

One of the defining characteristics of DTF transfers is their remarkable print quality. Utilizing advanced DTF printing technology, this method ensures that designs are rendered in vibrant, true-to-life colors that stand out. The ability to produce detailed images without compromising on depth or clarity provides a significant advantage in the competitive custom print market, allowing businesses to offer products that resonate with consumers.

Moreover, DTF transfers can be applied seamlessly to a wide range of fabrics, including cotton and polyester, which enhances the versatility of custom offerings. This adaptability, combined with the high resolution of prints, ensures that businesses are not limited by material choice, and can confidently appeal to diverse customer segments.

Cost-Effective Printing Solutions with DTF

In a world where cost management is vital, the affordability of DTF transfers makes them particularly appealing. By minimizing setup costs and eliminating the need for extensive equipment, businesses can operate with higher profit margins. This cost-effectiveness is essential for startups and smaller operations looking to carve a niche in the custom printing domain.

The batch printing capabilities of DTF technology allow companies to fulfill custom orders without incurring the high expenses typically associated with traditional printing methods. This not only reduces financial risk but also promotes sustainable practices by allowing businesses to print only what is needed, thus minimizing waste in line with modern consumer expectations.

DTF Technology’s Role in Streamlining Production

The implementation of DTF printing technology significantly enhances workflow efficiency, which is crucial for businesses aiming to maximize productivity. The straightforward learning curve associated with DTF processes allows for quicker staff training, ensuring that operations can swiftly adapt to this innovative printing method. Companies can achieve higher productivity without compromising quality, making them competitive in the fast-paced commercial landscape.

Furthermore, the direct application of DTF transfers onto garments simplifies the production stages involved in custom printing. This streamlined approach not only accelerates order fulfillment but also reduces the potential for errors, enabling businesses to maintain high customer satisfaction levels through accurate, timely deliveries.

Sustainability and Eco-Friendliness of DTF Transfers

As environmental concerns take center stage in consumer decision-making, the sustainability of DTF transfers plays a pivotal role in enhancing a brand’s appeal. DTF technology utilizes water-based inks, which are less harmful than traditional solvent-based alternatives. This environmentally friendly approach aligns businesses with the growing consumer demand for sustainable practices, positioning them favorably in a socially conscious market.

Additionally, the minimal waste associated with DTF transfers contributes to resource conservation, dovetailing with eco-friendly initiatives. By adopting DTF technology, companies can demonstrate their commitment to sustainability, potentially increasing customer loyalty while appealing to a demographic that values ethical and sustainable consumption.

Innovative Advancements in DTF Technology

The rapid evolution of DTF printing technology heralds exciting possibilities for the future of custom printing. Ongoing innovations in printer design and film materials are enhancing print quality and reducing production times, setting the stage for even more efficient manufacturing processes. As businesses increasingly invest in these advanced technologies, the potential for creating more durable and vibrant prints becomes a reality.

Moreover, with advancements in research and development, the custom printing industry can expect continual improvements in cost-effectiveness and operational efficiency. These innovations will empower businesses to keep pace with industry trends, further solidifying DTF’s role as a driving force in transforming how custom prints are produced.

DTF Transfers: A Solution for Businesses of All Sizes

DTF transfers offer an array of advantages, making them suitable for businesses of various scales, from startups to established corporations. For smaller operations, the cost-effective nature of DTF technology provides a gateway into the custom print market, letting them operate profitably while meeting specific customer demands. This accessibility is particularly beneficial for new entrepreneurs looking to establish a foothold in a competitive landscape.

On the other hand, established companies can leverage DTF transfers to diversify their product offerings significantly. By facilitating customization in print services, these businesses can respond to consumer demands for unique designs and personalized items, enhancing customer loyalty and driving repeat business in an increasingly crowded market.

Frequently Asked Questions

What are DTF Transfers and how do they enhance custom printing?

DTF Transfers, or Direct-to-Film transfers, are a revolutionary printing method that prints designs onto a special film, which is then applied to garments using heat and pressure. This technology enhances custom printing by producing high-quality prints with vibrant colors and complex designs, making it adaptable for various fabrics, including cotton and polyester, and ensuring a competitive edge for businesses.

How does DTF printing technology ensure cost-effective printing solutions?

DTF printing technology is considered cost-effective due to its lower setup costs compared to traditional screen printing. Businesses can produce small batches of custom orders without high overheads, which is especially beneficial for startups. Additionally, the efficient production process minimizes material waste, making it a financially viable option for companies looking to control costs.

What advantages do DTF Transfers offer in terms of print quality?

DTF Transfers stand out for their exceptional print quality, producing vibrant colors and enabling intricate designs that are difficult to achieve with traditional methods. This high-quality output appeals to a broad customer base, allowing businesses to cater to diverse tastes and preferences in the custom print market.

Can DTF Transfers be considered a sustainable printing option?

Yes, DTF Transfers are a sustainable printing option as they typically use water-based inks that are less harmful to the environment compared to solvent-based inks. This eco-friendly approach aligns with consumer values for sustainability, making it an appealing choice for businesses aiming to reduce their carbon footprint.

What types of fabrics can be used with DTF printing technology?

DTF printing technology is versatile and compatible with a variety of fabrics including cotton, polyester, and blends. This flexibility allows businesses to expand their product offerings and cater to different customer preferences, making DTF Transfers an ideal choice for various apparel and merchandise.

How does DTF Transfers improve workflow efficiency in custom printing?

DTF Transfers enhance workflow efficiency by simplifying the printing process. They require minimal training for staff as they are easier to use than traditional screen printing methods. The direct application of DTF prints to garments using heat presses reduces the number of production stages, speeding up order fulfillment and improving overall operational efficiency.

| Key Point | Description |

|---|---|

| Introduction | DTF transfers revolutionize the custom print industry by providing high-quality, efficient prints. |

| The Rise of DTF Transfers | A new printing method that simplifies the process, making it accessible to more businesses. |

| Print Quality and Versatility | DTF offers vibrant, high-quality prints on various fabrics with no complex setups. |

| Cost-Effectiveness | Lower setup costs and ability to print in small batches reduce financial burden. |

| Ease of Use and Workflow Efficiency | Simple learning curve and direct application streamline operations and order fulfillment. |

| Sustainability | Environmentally friendly inks align with consumer values, enhancing business reputation. |

| Technological Advancements | Ongoing improvements in DTF technology promise reduced costs and increased quality. |

| Advantages for Businesses | Suitable for various business sizes, enhancing customer satisfaction through customization. |

Summary

DTF Transfers have become a transformative force in the custom print industry, offering unparalleled advantages such as high-quality results, cost efficiency, and environmental sustainability. By simplifying the printing process and allowing for greater design flexibility, DTF technology enhances productivity for businesses of all sizes while meeting the demands of modern consumers who value personalization and eco-friendliness. As this innovative printing technique continues to evolve and gain traction, it is poised to shape the future landscape of custom printing even further.