In the exciting realm of custom apparel, DTF transfers have revolutionized the way designs are applied to fabrics. Standing for Direct to Film transfers, this innovative printing method allows for the creation of stunning, vibrant T-shirt designs that captivate audiences. Unlike traditional printing techniques, DTF printing offers versatility across a variety of fabrics, ensuring that artists and entrepreneurs can bring their creative visions to life with ease. This introductory guide will delve into the process of mastering DTF transfers, highlighting the key equipment needed and the distinctive benefits that set it apart from other T-shirt printing methods. Join us as we explore how DTF transfers can elevate your custom apparel game to new heights.

Direct to Film (DTF) printing, a cutting-edge approach in the T-shirt printing industry, brings immense potential for customization and design fidelity. Utilizing a unique transfer technique, this process involves printing on a specific film which is then heat-applied to various fabrics, producing eye-catching designs with vivid colors. Often associated with innovative custom apparel solutions, DTF technology has quickly gained popularity among small businesses and creative individuals for its adaptability and quality. As we navigate through the essentials of Direct to Film transfers, we’ll uncover the advantages this method offers over traditional printing techniques, making it a sought-after choice for modern textile artists. Whether you’re an aspiring maker or a seasoned pro, understanding DTF can open up a world of possibilities for your garment design endeavors.

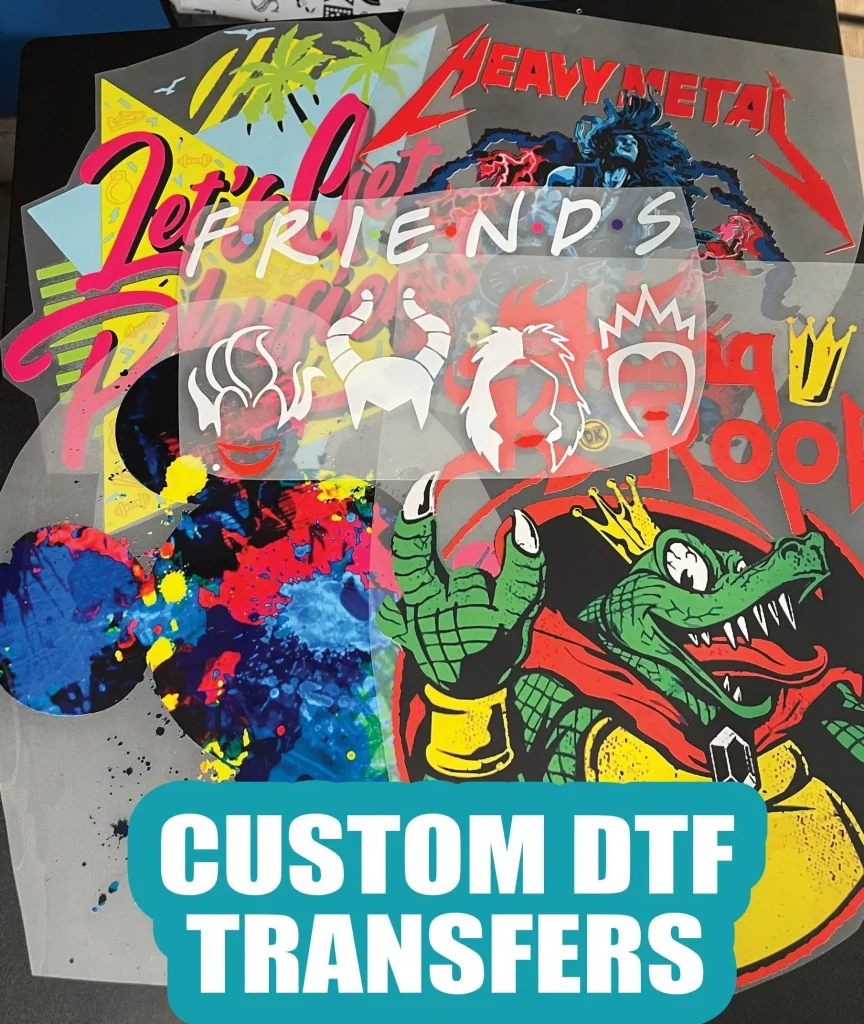

The Rise of DTF Printing in Custom Apparel

In recent years, DTF printing has gained significant traction among enthusiasts and professionals in the custom apparel industry. The appeal lies in its ability to produce vibrant and intricate designs that resonate with diverse consumer tastes. Unlike traditional printing methods, which often struggle with color accuracy and fabric compatibility, DTF printing excels by offering high-resolution outputs on various materials, making it a preferred choice for fashion designers, artists, and small businesses alike.

Furthermore, the user-friendly process of DTF transfers allows even novices to achieve professional-grade results without requiring extensive training or investment in professional printing equipment. The combination of affordability, versatility, and stunning color reproduction has made DTF printing the go-to solution for creating personalized T-shirts and other custom apparel, setting a new standard in the industry.

Understanding the DTF Printing Process

At its core, DTF printing is a remarkably straightforward yet effective method for transferring designs onto fabric. The process begins with the creation of a digital design, which is then printed onto a special DTF film using high-quality, pigment-based inks. This innovative printing technique ensures that vibrant colors are maintained during the transfer, giving each garment a striking and professional appearance.

Once printed, an adhesive powder is applied, which bonds with the ink during a heat curing process. This step is crucial for achieving long-lasting results, ensuring that the design can withstand wear and washing. With a heat press, the film is then applied to the chosen fabric, resulting in a final product that not only looks good but also endures over time. Understanding these steps is vital for anyone interested in producing high-quality apparel.

Essential Equipment for DTF Transfers

To embark on your DTF printing journey, you will require specific equipment to ensure success. The first item on your list should be a DTF printer, which is typically an inkjet printer suitable for printing on specially coated film sheets. The importance of using the right printer cannot be overstated, as it directly affects the quality of the final print. Additionally, investing in high-quality DTF film sheets is vital, as they are crucial for capturing the vibrancy of your designs.

Furthermore, you will need a reliable heat press to facilitate the transfer process. Heat presses come in various sizes and configurations, allowing you to choose one that fits your production needs. Finally, don’t forget about powder adhesive, which is essential for ensuring the ink adheres properly to the fabric. With the right equipment in your arsenal, you can master the art of DTF printing and produce stunning T-shirt designs.

Step-by-Step Guide to Creating DTF Transfers

Mastering the DTF transfer process begins with designing your graphics using popular design software such as Adobe Illustrator or CorelDRAW. Start by carefully setting your design’s dimensions and resolution to ensure that the final product is visually striking and sharp. Orientation is also key; make sure the design is flipped horizontally if necessary, marking the first step in achieving a successful transfer!

Next, print your design onto the selected DTF film. One of the critical elements of this step is ensuring that your printer is set to the correct specifications for capturing the nuances of your artwork. Once printed, apply the adhesive powder evenly over the moist ink. This step is crucial to secure the design during the heat press application, which is the final procedure that brings your masterpiece to life on the fabric.

Benefits of Choosing DTF Transfers for T-Shirt Printing

DTF transfers present a myriad of advantages, making them a top choice for those interested in T-shirt printing. One of the foremost benefits is versatility; the ability to print on different types of fabrics—be it cotton, polyester, or blends—opens the door to a wide range of apparel options. This adaptability allows businesses to cater to diverse customer demands and trends.

Moreover, the vibrant colors and high-quality prints produced through DTF technology ensure that each T-shirt stands out. Customers often gravitate towards bold designs, making this method ideal for creating striking and fashionable custom apparel that appeals to a wide audience. When done correctly, DTF transfers not only enhance product offerings but also foster brand loyalty by delivering quality that customers can trust.

Emerging Trends in DTF Printing

As the DTF printing market continues to grow, several trends have emerged that shape the future of custom apparel. One notable trend is the increasing accessibility of DTF technology, allowing entrepreneurs and hobbyists to enter the market with relatively low startup costs. This democratization of apparel printing means that more individuals can experiment with their creative ideas and produce unique designs.

Additionally, the rise of eco-friendly materials in DTF printing has gained momentum. More consumers are becoming aware of sustainability, pushing brands to explore eco-conscious fabrics and inks. This movement not only meets consumer demand but also promotes environmental responsibility within the industry, highlighting the progressive nature of DTF printing as it evolves to cater to modern values and preferences.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a type of printing method where designs are printed onto a specially coated film and then transferred onto fabric. The process involves using a DTF printer to create the design, applying a powdered adhesive to the ink, and then using heat and pressure to bond the design to the material, resulting in vibrant T-shirt prints.

What equipment do I need for DTF printing for T-shirts?

To effectively execute DTF printing, you need a DTF printer that accommodates film sheets, DTF film sheets for printing the designs, powdered adhesive to ensure ink adherence, and a heat press to transfer the design onto the T-shirt. This combination facilitates high-quality and durable customization.

What are the advantages of using DTF transfers over other printing methods?

DTF transfers offer several advantages, including versatility across various fabric types, high-quality prints with rich colors, and excellent durability against fading and peeling. This makes DTF a superior choice for custom apparel, especially for designs that require intricate detailing.

Can I use DTF printing on different types of fabrics?

Yes, DTF printing is versatile and can be used on a range of fabrics, including cotton, polyester, and blends. This adaptability allows for custom T-shirt designs that cater to different styles and fabric preferences, making it a popular choice for custom apparel.

How do I ensure a high-quality transfer when using DTF printing?

To achieve high-quality DTF transfers, it is essential to use optimal printer settings when printing on DTF film, ensure proper curing of the adhesive, and use the correct temperature and pressure during the transfer process. These steps will enhance adhesion and image clarity, ensuring vibrant T-shirt designs.

What are common applications for DTF transfers in custom apparel?

Common applications for DTF transfers in custom apparel include T-shirt printing for businesses, promotional items, artistic endeavors, and personalized gifts. The vibrant designs and adaptability to various fabrics make DTF printing ideal for creating unique fashion statements and branded merchandise.

| Key Points | Description |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on a special film and then applying them to fabrics using heat and pressure. |

| Equipment Needed | 1. DTF Printer, 2. DTF Film Sheets, 3. Powder Adhesive, 4. Heat Press |

| Step-by-Step Process | 1. Design Creation, 2. Printing the Design, 3. Curing the Adhesive, 4. Transfer to Fabric, 5. Post-Processing |

| Benefits of DTF Transfers | 1. Versatility, 2. High-Quality Prints, 3. Durability |

| Current Trends | Growing market for small businesses leveraging custom apparel opportunities due to advancements in DTF technology. |

Summary

DTF transfers have revolutionized the custom apparel sector, allowing for high-quality and vibrant designs on various fabrics. This innovative printing method not only ensures adaptability across fabric types but also offers durability that withstands frequent washing and wearing. By mastering DTF transfers, individuals can unlock new creative avenues and business potentials, catering to a wide audience with unique apparel solutions.