DTF transfers, or Direct-to-Film transfers, have emerged as a revolutionary technique in the realm of custom apparel printing. This advanced technology is changing the way vibrant prints are created, providing exceptional durability and stunning color retention on a variety of fabrics. As traditional printing methods face challenges such as environmental impact and limited material compatibility, DTF technology stands out with its ability to integrate sustainable printing practices without sacrificing quality. The increasing demand for personalized clothing options has propelled DTF into the spotlight, making it a preferred choice for businesses seeking to meet consumer needs while adhering to eco-friendly standards. In this blog post, we will delve into DTF transfers, exploring their advantages, recent innovations, and how they are shaping the future of the apparel printing industry.

Direct-to-Film transfers represent a significant advancement in the landscape of fabric printing, offering a versatile solution for those in the custom apparel sector. Often compared to other methods like sublimation, DTF technology excels by providing an efficient means of producing high-quality, vibrant prints on a broader range of materials. This sustainable printing method appeals to environmentally-conscious brands and consumers alike, as it reduces waste and utilizes innovative processes. By enabling detailed designs that resonate with a variety of applications, DTF transfers are setting new standards for creativity and production in the apparel market. As interest grows, understanding the dynamics of DTF printing versus traditional techniques will be crucial for anyone looking to enhance their printing capabilities.

Understanding DTF Transfers: The Future of Custom Apparel Printing

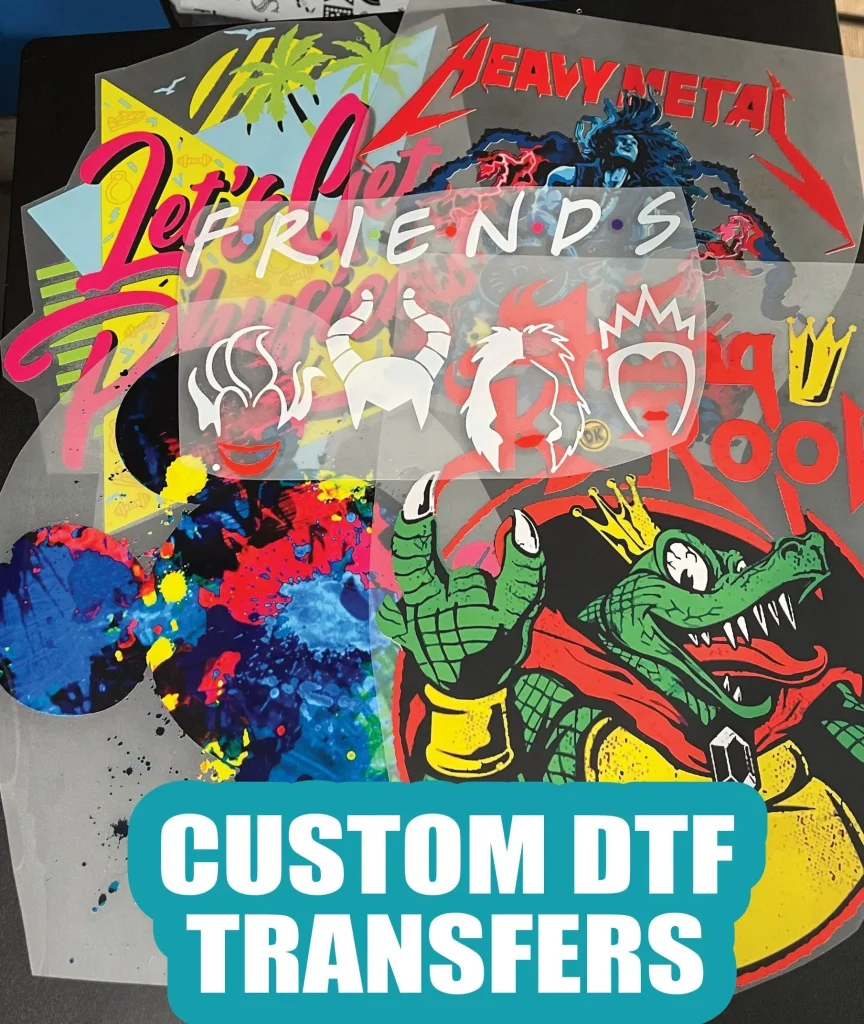

DTF transfers, or Direct-to-Film transfers, represent a significant advance in the custom apparel printing industry. This innovative technique involves printing designs onto a specialized film, which is then heat-pressed onto fabric. The result is a vibrant, high-quality print that can adhere to various materials, setting DTF apart from traditional printing methods like screen printing. The use of unique binding agents in DTF technology enhances color retention and minimizes fading, ensuring the prints maintain their brightness and integrity even after multiple washes.

Compared to other methods such as sublimation printing, DTF offers remarkable versatility. While sublimation is limited to polyester and similar fabrics, DTF is compatible with cotton, blends, and more. This flexibility opens new avenues for custom apparel creation, allowing designers and businesses to cater to a wider audience with diverse fabric choices. As a result, the demand for DTF transfers has surged, making it a game-changer for companies looking to produce high-quality, durable prints efficiently.

Sustainability in DTF Printing: An Eco-Friendly Choice

The rise of DTF technology is closely tied to the growing awareness around sustainability in the fashion and printing industries. Unlike traditional methods that often produce significant waste and use harmful chemicals, DTF transfers advocate for a more eco-friendly approach. By utilizing cleaner processes and materials, DTF is not only reducing its environmental footprint but also appealing to consumers who prioritize sustainability in their purchasing decisions.

As brands increasingly seek sustainable printing options to meet consumer expectations, DTF provides a responsible alternative without compromising on quality. With its ability to produce vibrant prints that last while minimizing waste, DTF is paving the way for a more environmentally conscious apparel industry. This commitment to sustainability aligns with the broader trend of brands incorporating green practices into their operational models, making DTF a preferred choice for many businesses striving for eco-friendly solutions.

Additionally, the DTF printing process requires less energy than traditional methods, further enhancing its sustainability credentials. This feature is particularly important in an age where energy consumption and resource management are critical factors in production. By opting for DTF transfers, businesses not only invest in superior print technology but also contribute to the shift toward a more sustainable future.

Comparing DTF and Sublimation Printing: Which is Better?

When it comes to custom apparel printing, the debate between DTF and sublimation is often at the forefront. Sublimation printing is celebrated for its ability to produce vibrant, full-color prints that seamlessly integrate into fabrics, primarily polyester. However, this method’s limitations in material compatibility can restrict creativity and design options. In contrast, DTF transfers are gaining traction due to their adaptability across a broader range of materials, including cotton and canvas, providing much-needed flexibility for designers.

Furthermore, DTF’s use of specialized binding agents results in prints that possess remarkable durability and vibrancy. Users report that DTF prints retain their quality without cracking, fading, or peeling over time, advantages that are particularly crucial for businesses focusing on longevity and customer satisfaction. This distinct operational advantage positions DTF as a formidable contender in the custom printing landscape, allowing brands to meet consumer demand for diverse fabric choices while maintaining high standards in print quality.

Technological Innovations in DTF Transfer Printing

Advancements in DTF technology have transformed the landscape of custom apparel printing. Innovations such as automated printers and improved film materials have streamlined the printing process, making it faster and more cost-effective. One standout product is the xTool Apparel Printer, which has simplified DTF printing for hobbyists and small businesses, enabling them to create unique custom designs with minimal effort. This accessibility encourages creativity, enabling users to explore their design ideas without the burden of complex setup procedures.

Moreover, technological innovations in the DTF sector facilitate high-quality output while accommodating varying production scales. Companies are now able to efficiently cater to both small-batch and large-volume orders, a feature that makes DTF an attractive option for businesses looking to expand their reach in the custom apparel market. As technology continues to evolve, businesses can expect even greater capabilities and efficiencies that will further drive the adoption of DTF printing solutions.

The Expanding Market for DTF Printing Solutions

As the popularity of DTF printing solutions continues to grow, the market is experiencing significant expansions. Companies like EazyDTF are investing heavily in large format DTF technology to meet a rising demand from various sectors, including retail, events, and personalized merchandise. This surge in interest showcases the versatility and effectiveness of DTF as a printing solution that meets diverse consumer needs. Businesses of all sizes are seizing the opportunity to incorporate DTF technology into their offerings, fueling market growth and competition.

The influx of investments in DTF technology underlines a shift in the apparel industry’s focus, moving towards efficient, high-quality, and sustainable printing solutions. As brands explore new avenues for customization and personalization, the demand for DTF products is expected to increase substantially. This trend not only reflects the evolving preferences of consumers but also indicates a broader acceptance of innovative printing technologies that enhance operational efficiency and product quality.

Custom Apparel and DTF Transfers: A Perfect Match

DTF transfers have emerged as a perfect match for the ever-evolving world of custom apparel. With their ability to offer vibrant prints and adhere to various fabric types, they provide businesses with the flexibility needed to cater to consumers’ desires for personalized clothing. Whether it’s for promotional merchandise, individual designs, or bulk orders, DTF technology allows retailers to produce stunning products that stand out in a crowded market.

In the custom apparel sector, the combination of creativity and technology is crucial. DTF printing empowers designers to experiment with different styles and fabrics, dramatically expanding their product offerings. This technological capability enables brands to remain competitive as they adapt to changing fashion trends and consumer preferences, allowing them to deliver unique, high-quality apparel that resonates with customers.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF Transfers, or Direct-to-Film transfers, are an innovative method in custom apparel printing that involves printing designs onto a special film. This film is then heat-pressed onto various fabric types. Unlike traditional screen printing or sublimation, DTF utilizes specific binding agents that enhance color vibrancy and durability, making it a favored choice for unique and high-quality prints.

How does DTF technology promote sustainable printing practices?

DTF technology promotes sustainable printing practices by significantly reducing waste compared to traditional methods. It employs cleaner processes and lower environmental impacts, making it an eco-friendly alternative in custom apparel printing. As consumers increasingly seek sustainability, DTF’s capabilities in producing vibrant prints while minimizing waste align well with environmentally-conscious trends.

What are the advantages of using DTF transfers over sublimation printing?

DTF transfers offer several advantages over sublimation printing, particularly in versatility and fabric compatibility. While sublimation is ideal for polyester fabrics, DTF technology adheres to a broader range of materials, providing vibrant prints that fulfill diverse printing needs. This makes DTF a more effective solution for various custom apparel applications.

How do DTF Transfers ensure high-quality and durable prints on apparel?

DTF Transfers ensure high-quality and durable prints through their unique printing process that uses specialized binding agents. These agents enhance the adherence of vibrant colors to different fabrics, resulting in prints that are less prone to fading or cracking over time. This quality makes DTF an attractive choice for long-lasting custom apparel.

Is DTF printing a cost-effective solution for small batch custom apparel orders?

Yes, DTF printing is considered cost-effective for small batch custom apparel orders. Unlike traditional printing methods that often involve higher setup costs for screens and molds, DTF allows for lower investment while still producing high-quality prints, making it accessible for small businesses and hobbyists looking to create personalized designs.

What innovations in DTF technology are shaping the future of custom apparel printing?

Recent innovations in DTF technology, such as the development of user-friendly DTF printers like the xTool Apparel Printer, are making custom apparel printing more accessible. These advancements facilitate rapid production of vibrant, personalized designs, meeting the growing consumer demand for unique apparel while emphasizing sustainability and efficiency in the printing process.

| Key Points | Details |

|---|---|

| Introduction | DTF (Direct-to-Film) transfers are revolutionizing custom apparel printing with vibrant and durable prints. |

| What Are DTF Transfers? | A printing process where designs are printed on a film and heat-pressed onto fabrics, utilizing binding agents for better adherence. |

| Recent Developments | 1. Reduction of waste promoting sustainability. 2. Greater versatility compared to sublimation printing. 3. New technologies like the xTool Apparel Printer making it more accessible. 4. Industry expansion with increased production capabilities. |

| Advantages of DTF Transfers | – Versatility across various fabrics. – High quality and durability. – Cost-effective for small batches. – User-friendly process. |

| Future of Custom Printing | DTF is seen as a key player in the eco-friendly future of custom printing, addressing consumer demand for personalization. |

Summary

DTF Transfers represent a significant shift in the custom apparel printing landscape, offering a vibrant, versatile, and sustainable solution for both businesses and hobbyists alike. The technology empowers users to create high-quality designs that adhere well to a wide range of fabrics, ensuring durability and preserving vivid colors over time. As the industry continues to evolve towards sustainability and personalization, DTF Transfers are set to not only meet the demands of eco-conscious consumers but also to drive innovation in custom printing practices. This commitment to quality and efficiency positions DTF Technologies favorably in the competitive world of apparel printing.