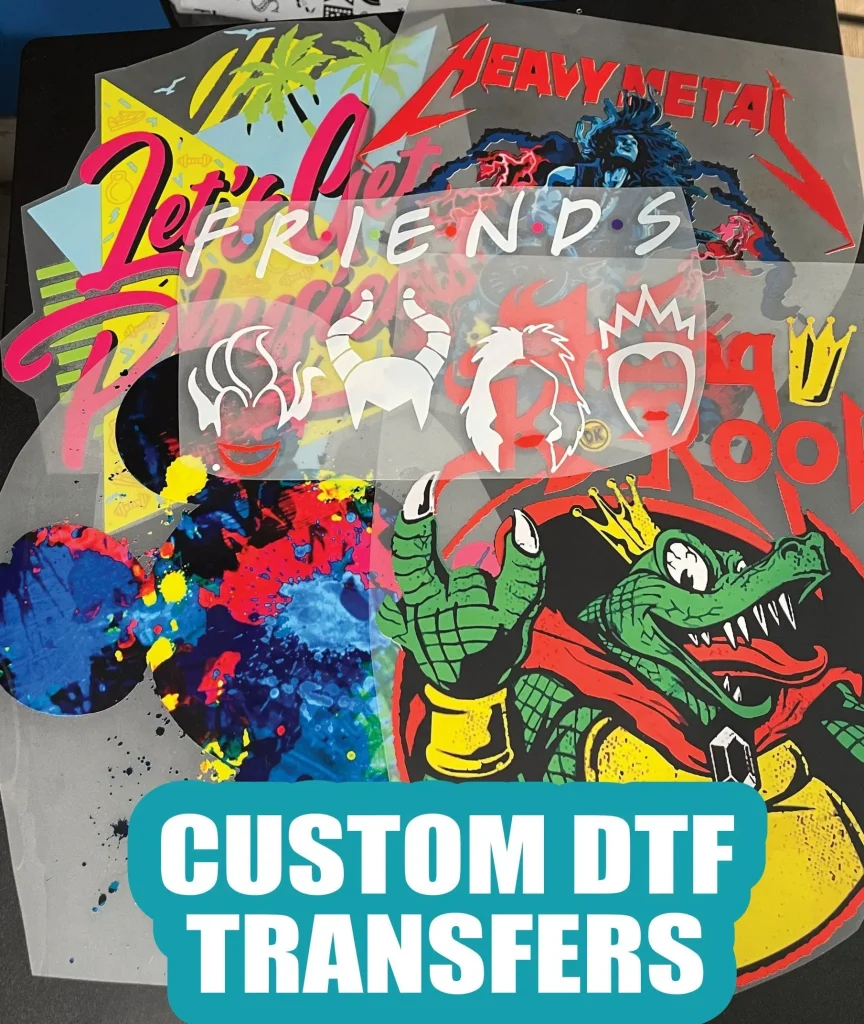

DTF transfers, or Direct to Film printing, have emerged as a game-changing technology in the realm of custom apparel, offering businesses a revolutionary way to bring their designs to life. This advanced apparel printing technology allows for high-quality prints that feature vibrant colors and intricate details, far surpassing traditional methods. With the ability to print on a variety of fabrics, DTF transfers are rapidly becoming the preferred choice for companies looking to make their mark in a competitive marketplace. As the demand for customized clothing continues to grow, understanding the unique benefits of DTF printing is essential for both creators and entrepreneurs. Join us as we explore how this innovative printing solution is reshaping the landscape of apparel production and setting new standards for quality and creativity.

Direct to Film printing, also known as DTF transfers, is revolutionizing the way designs are applied to textiles in the custom apparel industry. This dynamic printing method harnesses cutting-edge technology to achieve vibrant and long-lasting prints, catering to a diverse range of fabric types. The rising popularity of this printing technique can be attributed to its versatility and efficiency, making it an attractive option not only for large businesses but also for small startups. As apparel printing technology advances, DTF transfers stand out as a solution that combines creativity with practicality, enabling brands to deliver high-quality products that resonate with consumers.

Understanding DTF Printing Technology

Direct to Film (DTF) printing represents a significant leap in apparel printing technology, allowing for incredibly detailed and vibrant designs to be applied to a wide array of garments. The process begins with printing on a specialized film using high-quality, water-based inks, which ensures that every nuance of the design is captured vividly. After printing, a powdered adhesive is applied, making it ready for heat transfer onto fabrics. This method not only boasts exceptional durability but also stands out for its versatility across various types of fabric, such as cotton, polyester, and blends. As a result, DTF technology has rapidly gained popularity among custom apparel creators looking to push the boundaries of their designs and offerings.

DTF printing technology excels in its process simplicity compared to traditional methods like screen printing. In contrast to screen printing’s lengthy setup times and color limitations, DTF allows for direct printing of full-color graphics without the need for screens or plates. This efficiency translates to a quicker turnaround time for orders, making it a perfect fit for businesses that thrive on flexibility and speed. Additionally, the ability to produce small runs without significant setup costs ensures that both established companies and startups can benefit from high-quality prints without risking overstock or excessive waste.

Furthermore, businesses can easily shift designs based on market trends and customer feedback due to the low initial investment with DTF printing. This adaptability is particularly vital in today’s fast-paced retail environment, where fashion trends can change overnight. The user-friendly nature of DTF transfer technology means that more brands can adopt it without extensive training or equipment investment, making it increasingly accessible for new entrepreneurs and established fashion houses alike.

The Benefits of DTF Transfers for Custom Apparel

One of the standout benefits of DTF transfers is their ability to produce visually striking, high-quality prints that elevate custom apparel. The unique process combines advanced pigment inks with a proprietary adhesive, ensuring that prints retain their vibrancy even after multiple washes. This longevity is essential for businesses wanting to create apparel that not only looks good upon purchase but continues to impress customers over time. Brands can confidently market their products knowing they are backed by high standards of durability, helping to build a loyal customer base eager to repeat purchases.

Moreover, DTF transfers provide an eco-friendly solution for apparel printing. The use of water-based inks reduces harmful solvents in the environment, aligning with the growing trend of sustainability among consumers. Many businesses are seeking ways to minimize their carbon footprint, making DTF technology an attractive alternative. The process generates less waste compared to traditional printing methods, allowing companies to engage in responsible manufacturing practices while still delivering high-quality products.

The customizability that DTF transfers afford also caters to a diverse range of design styles, from intricate artworks to bold graphic logos. This versatility empowers custom apparel creators to cater to niche markets and varied customer preferences, ultimately driving their sales and brand recognition.

DTF Transfers: A Cost-Effective Solution for Startups

For startups looking to break into the custom apparel market, DTF transfers offer an economical choice that aligns with budget-conscious business models. One of the most appealing features is the lack of minimum order requirements, allowing businesses to experiment with designs and order small batches without overstretching their finances. This flexibility facilitates market testing, enabling new brands to gauge customer responses before committing to large production runs.

Additionally, DTF transfers streamline the production process, reducing labor costs associated with more traditional printing methods. With its quick application and heat transfer capabilities, startups can achieve a faster turnaround time, meeting the demands of a growing consumer base without sacrificing quality or aesthetics. This efficiency not only saves money but also positions new businesses to respond swiftly to market trends and capitalize on emerging opportunities.

Innovations in DTF Transfer Technology Continues

The landscape of DTF transfer technology is ever-evolving, with continuous innovations enhancing the capabilities of this printing process. Manufacturers are constantly developing improved inks and adhesives that ensure better adhesion and richer color output. Enhanced DTF printers are being engineered to provide even higher resolutions, allowing for breathtaking detail in designs that draw attention in any retail setting. These advancements make DTF printing increasingly competitive with other apparel printing technologies, setting new benchmarks for quality and efficiency.

Moreover, as the technology evolves, so are the tools and platforms available for those in the custom apparel industry. New software solutions are designed to simplify the design process for users at all skill levels, ensuring that creativity is not hampered by a steep learning curve. These breakthroughs mean that aspiring designers can produce high-quality prints that showcase their unique style while leveraging robust advancements in DTF technology.

The Future of Custom Apparel with DTF Printing

Looking ahead, the future of custom apparel appears bright with the growing adoption of DTF printing technology. As brands and businesses increasingly recognize the advantages of DTF transfers—such as high-quality prints, versatility, and affordability—they are more likely to incorporate this method into their production strategies. This widespread acceptance could lead to an even broader range of apparel options available to consumers, catering to diverse tastes and lifestyle preferences.

As advancements in DTF technology continue to emerge, we can expect to see even greater accessibility for brands of all sizes. Innovators in this space will likely expand their offerings, integrating DTF printing solutions that enhance productivity and quality even further. The transformative potential of DTF transfers indicates a significant shift in the manufacturing practices of custom apparel, promising to improve the industry’s efficiency and compatibility with modern consumer demands.

Understanding Market Trends in DTF Transfers

As the custom apparel market evolves, understanding consumer trends is crucial for businesses that want to thrive amidst competition. DTF transfers are increasingly becoming preferred among creators seeking to adapt to shifts in buyer behavior, such as the demand for personalized and unique apparel. The ability of DTF printing to manifest complex designs quickly, without the need for large inventories, is aligning perfectly with the growing desire for customizable fashion options.

Moreover, consumer preferences toward sustainability and ethical production are driving brands to reevaluate their manufacturing processes. DTF technology, being inherently eco-friendly due to its minimal waste approach and water-based inks, is well-positioned to satisfy both environmental consciousness and the increasing demand for high-quality products by increasingly discerning consumers. This alignment with market expectations not only bolsters brand loyalty but also opens avenues for dramatic growth in sustainable fashion sectors.

Frequently Asked Questions

What are DTF transfers and how do they improve custom apparel printing?

DTF transfers, or Direct to Film transfers, are a modern printing method that utilizes a special film to transfer vibrant designs onto fabrics. This advanced apparel printing technology produces high-quality prints with vivid colors and exceptional durability, making it an ideal choice for custom apparel.

Why are DTF transfers becoming popular in the custom apparel industry?

The popularity of DTF transfers in custom apparel stems from their versatility, allowing for excellent prints on various fabric types, and cost-effective solutions, as there are no minimum order requirements. This flexibility appeals to both small startups and established brands looking for rapid and high-quality apparel printing.

How do DTF printing and traditional methods compare in terms of quality and durability?

DTF printing surpasses traditional methods like screen printing in terms of quality and durability. DTF transfers create high-quality prints with detailed designs and vibrant colors, using water-based inks and adhesives that ensure long-lasting results on apparel.

Can DTF transfers be applied to all types of fabrics?

Yes, one of the significant advantages of DTF transfers is their compatibility with various fabric types. DTF technology excels in adhering to materials such as cotton, polyester, and blends, making it a versatile choice for different custom apparel needs.

What cost advantages do DTF transfers offer for custom apparel businesses?

DTF transfers provide cost-effective solutions for custom apparel production by eliminating minimum order requirements. This allows small to medium-sized businesses to produce small batches without the risk of overproduction, making it ideal for testing new designs and managing costs.

What innovations are shaping the future of DTF transfer technology?

Innovations in DTF transfer technology, such as new heat transfer products from companies like Insta Graphic Systems and user-friendly platforms for crafters, are shaping the future of custom apparel. These advancements aim to enhance print quality and accessibility, driving the trend of DTF transfers in the apparel industry forward.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers use special film and heat to transfer designs onto fabrics, offering vibrant colors and durability. |

| Popularity Surge | DTF is favored by small and large businesses due to quick turnaround times and no minimum order requirements. |

| High-Quality Prints | Uses water-based inks for vibrant, lasting prints that capture intricate designs. |

| Versatility in Fabric Types | Compatible with various fabrics, including cotton and polyester. |

| Cost-Effective Solutions | No minimum order allows for testing designs with low risk for startups. |

| Innovations in Technology | Companies are constantly developing new DTF products to enhance printing capabilities. |

| Future Impact | Increasing accessibility and affordability in the custom apparel market driven by DTF. |

Summary

DTF transfers are rapidly transforming the landscape of custom apparel, providing businesses with an innovative method to produce vibrant and durable prints. This technology not only supports a diverse range of fabric types but also offers cost-effective solutions, making it a preferred choice across the industry. As advancements continue and companies embrace DTF technologies, the potential for creative expression in apparel design is boundless, catering to current consumer trends and preferences.