DTF transfers, or Direct to Film transfers, are quickly gaining recognition for their transformative impact on custom apparel printing. This innovative DTF printing technology enables creators to produce vibrant, durable designs that adhere to various fabric types with ease. As we progress further into 2025, the DTF transfer market growth becomes a focal point for both entrepreneurs and small business owners looking to capitalize on the booming custom printing industry. Staying updated on the latest trends in DTF transfers will help individuals navigate this competitive field and leverage the advantages offered by this cutting-edge method. In this article, we will delve into the top trends shaping DTF transfers, from technological advancements to best practices for application.

In the realm of modern printing, Direct to Film (DTF) technology stands out as a revolutionary approach for custom apparel production. Often referred to simply as film transfers, this printing technique offers creatives an exciting avenue to showcase their designs on a variety of fabrics. As the market for film transfer solutions expands, small enterprises can now find accessible means to enter the custom printing sector. This shift promotes greater accessibility and convenience for individuals aiming to explore their artistic potential. By examining key trends, such as the surge in market demand and advancements in DTF printing processes, we can better understand the future outlook for this innovative printing method.

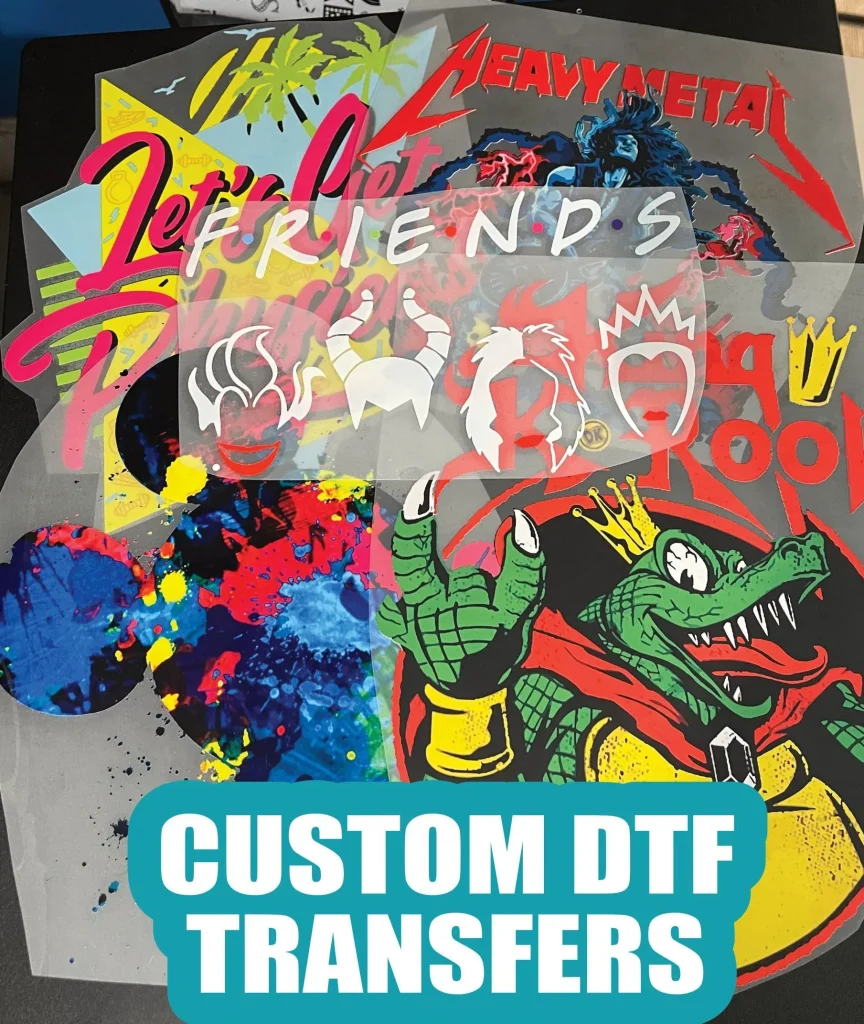

The Benefits of Using DTF Transfers for Custom Apparel

DTF transfers are becoming increasingly popular for custom apparel printing due to their numerous benefits. One of the most significant advantages is their ability to deliver vibrant colors that truly stand out on various fabrics. This is particularly important for businesses that want their designs to catch the eye of potential customers. DTF printing technology allows for detailed designs without compromising on quality, which can be a game-changer in a competitive market where first impressions are vital.

In addition to the aesthetic quality, DTF transfers offer exceptional durability. This means that once applied, the prints withstand multiple washes without losing their vibrancy or peeling off. For small business DTF operators, this durability translates into higher customer satisfaction and repeat business, as consumers are more likely to return for products that maintain their beauty over time. Additionally, the flexibility of DTF printing means it can be applied to a wide variety of materials and items, making it a versatile option for any printing project.

Frequently Asked Questions

What are DTF transfers, and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, are a modern printing technique that allows for high-quality custom apparel printing. This process involves printing designs onto a special film using DTF technology, which is then applied to fabric using heat and pressure. This method offers vibrant colors and exceptional durability, making it popular among small businesses and individuals looking to create unique clothing.

Why are DTF transfers becoming the preferred choice in the custom printing market?

The increasing popularity of DTF transfers stems from their flexibility and ease of use compared to traditional methods. They allow small business owners to produce high-quality prints without needing extensive machinery. Additionally, the vibrant colors and durability of DTF prints meet the demands of modern consumers, driving significant growth in the DTF transfer market.

How has the DTF transfer market grown in recent years?

The DTF transfer market has experienced considerable growth due to rising demand for customizable apparel. More entrepreneurs are entering this space, aided by the availability of DTF printing supplies and equipment from online platforms. This increased accessibility enables aspiring business owners to participate in the custom apparel printing industry with lower initial investments.

What are some technological advancements in DTF printing technology?

Recent advancements in DTF printing technology include improved ink formulations and enhanced printer capabilities specifically designed for DTF transfers. These innovations have led to better print quality, heightened vibrancy, and increased durability of the designs. As technology continues to evolve, these enhancements are expected to further boost the efficiency and appeal of DTF transfers.

What are the best practices for applying DTF transfers to fabrics?

To achieve optimal results with DTF transfers, it is essential to choose the right equipment, ensure ink compatibility, and prepare the fabric surface properly. Following manufacturer guidelines for heat setting and pressure is also critical. Testing with similar fabrics before tackling large orders can prevent mishaps and ensure the final product meets quality standards.

Can small businesses benefit from using DTF transfers?

Yes, small businesses can greatly benefit from DTF transfers. This printing method provides a cost-effective way to create high-quality custom apparel, appealing to a wide range of customers. As the DTF transfer market continues to grow, employing this technology allows small business owners to differentiate themselves and provide unique products, thereby increasing their competitiveness in the custom printing industry.

| Trend | Key Points |

|---|---|

| Growing Popularity | Increasing use for personal and commercial purposes; ideal for beginners. |

| Market Availability and Growth | Expansion of supplies and DTF printing services available online and locally. |

| Technological Enhancements | Improved inks and films, enhanced software, and printer technology for better performance. |

| Best Practices | Proper equipment choice, ink compatibility, surface preparation, and testing are crucial. |

Summary

DTF transfers are transforming the printing industry, offering a mix of vibrancy and durability that sets them apart from traditional methods. As the world of custom apparel evolves through 2025, trends such as increasing popularity, enhanced market availability, and ongoing technological advancements highlight the potential and practicality of DTF transfers. By embracing best practices for application, users can maximize the quality of their prints, making DTF an essential tool for both enthusiasts and business owners alike. Staying informed on these trends is vital for success in the competitive landscape of custom printing.