DTF Transfers, or Direct to Film transfers, are transforming the landscape of custom apparel printing, offering a fresh and innovative approach to garment design. This technology stands out for its ability to produce high-quality, vibrant prints that can adhere to various fabrics with ease. With the increasing popularity of DTF printing among beginners and seasoned designers alike, understanding its advantages is essential for anyone looking to enhance their creative repertoire. This guide will delve into the DTF transfer process, equipment requirements, and the multitude of benefits that make it a favorite choice for custom apparel. Whether you’re an entrepreneur or a hobbyist, DTF transfers open up new avenues for creativity and efficiency in the print market.

Direct to Film transfers, commonly referred to as DTF printing, are gaining momentum as a preferred method for creating custom designs on apparel. This printing technique not only facilitates the application of intricate and colorful artwork but also allows for flexibility in fabric compatibility. As more individuals venture into the world of garment customization, understanding the nuances of DTF printing for beginners will empower them to maximize the potential of this method. With a focus on the DTF transfer process and its practical advantages, this guide aims to provide insights for those looking to incorporate this technology into their creative projects. As the demand for personalized clothing increases, so does the effectiveness of DTF technology in meeting diverse consumer needs.

Understanding DTF Transfers: The Basics

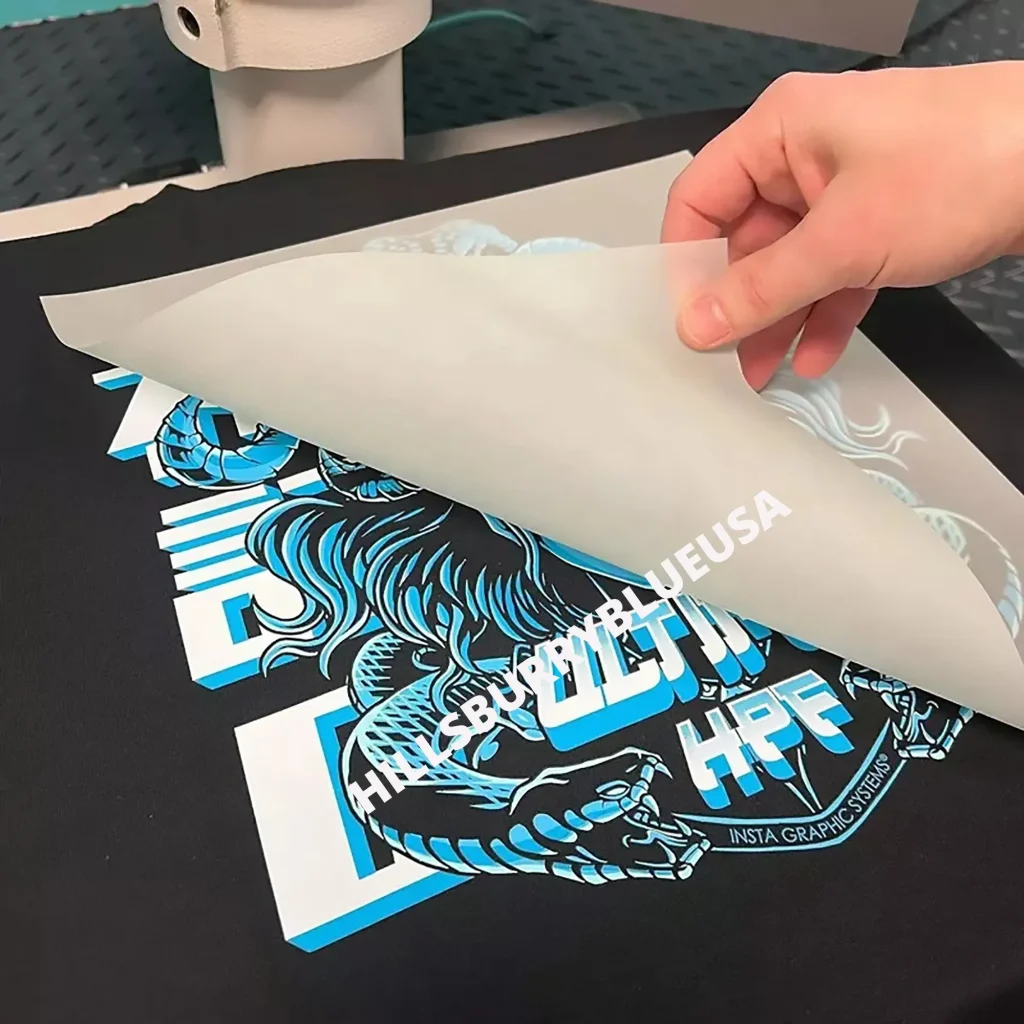

DTF transfers, or Direct to Film transfers, mark a revolutionary approach in fabric printing technology. This innovative method involves printing a design onto a specialized film, which is then transferred to the desired fabric using a heat press. The process stands out for its ability to render intricate designs with vibrant colors and detail, making it a favored choice for custom apparel and merchandise. Unlike traditional screen printing, which relies on a series of screens to apply color one layer at a time, DTF printing streamlines this process into a single transfer that can be applied quickly and efficiently.

The versatility of DTF transfers cannot be overstated. They are suitable for various materials, including cotton, polyester, and blends, allowing creators to explore a wide array of custom products ranging from t-shirts to tote bags. Moreover, the potential to print complex, multicolored designs without extensive setup time makes DTF printing particularly appealing for small businesses and individual designers looking to create high-quality, personalized items.

The Advantages of DTF Printing for Custom Apparel

One of the standout advantages of DTF printing is its ability to produce incredibly vibrant colors. This technology allows for high-resolution prints that can easily stand out in the crowded custom apparel market. The vividness of DTF prints draws attention and adds a professional touch to whatever fabric it is applied to, significantly enhancing the appeal of custom garments. Additionally, DTF transfers exhibit outstanding durability; once printed, these designs withstand frequent washing and wearing without fading, ensuring that the end products maintain their stunning appearance over time.

Another key advantage is the flexibility it offers in terms of order size. DTF printing eliminates the need for high minimum order quantities, which is often a barrier for many newcomers in the custom apparel business. This means that hobbyists and small entrepreneurs can create smaller batches or even one-off designs without incurring high setup costs, making it accessible for a wide range of users. This adaptability further establishes DTF printing as a preferred choice for bespoke projects.

Getting Started with DTF Printing: Essential Equipment

To embark on your DTF printing journey, certain essential equipment is necessary. Firstly, investing in a specialized DTF printer is crucial; this device utilizes a unique kind of plastic ink that is compatible with the transfer film. It’s important to research and select a printer that suits both your budget and production needs to optimize your printing capabilities. Moreover, the choice of transfer film plays a significant role in the overall quality of your prints, so sourcing high-grade materials is advisable.

In addition to the printer and transfer film, having a reliable heat press is fundamental to the DTF transfer process. The heat press applies the necessary temperature and pressure to adhere the print to the garment successfully. Experimenting with different heat settings can help identify the optimal combination for various fabrics, ensuring high-quality results. Overall, understanding the right equipment will set a solid foundation for your DTF printing endeavors.

Best Practices for DTF Printing Success

Achieving success in DTF printing begins with good practices, particularly regarding the quality of your artwork. Always utilize high-resolution images and consider working with vector graphics to maintain clarity when scaling designs. This attention to detail ensures that the final prints reflect the quality and professionalism that customers expect from custom apparel.

Additionally, continual experimentation with heat press settings cannot be overlooked. Different types of inks and fabrics may require different temperature and pressure settings to achieve optimal results. Keeping notes on various trials can help streamline processes and improve the consistency of outcomes over time, leading to more satisfying purchases for the customers.

Exploring Recent Innovations in DTF Technology

The advancements in DTF technology are remarkable, and they continuously redefine how custom apparel is produced. Recent innovations have brought about improved color management systems within newer DTF printers, ensuring that color consistency remains high across multiple prints. This enhancement not only improves the quality of the finished products but also boosts the efficiency of production for businesses.

Another exciting development is the introduction of eco-friendly inks and materials. As consumer awareness of environmental issues rises, companies that incorporate sustainable practices into their production not only help the planet but also attract a growing segment of eco-conscious customers. Staying informed about these innovations allows businesses to maintain a competitive edge while contributing positively to their community.

Success Stories in DTF Printing: Inspiration for Beginners

Many small business owners are turning to DTF printing as a means to invigorate their operations. For example, one entrepreneur related their journey of incorporating DTF transfers into their business model. By adding intricate designs and diverse personalization options, they reported a 50% boost in sales, highlighting how embracing this innovative technology can lead to significant business growth. This success story exemplifies the remarkable potential that DTF printing holds for those willing to adapt and invest in their creative processes.

These inspirational narratives not only provide motivation for beginners in the DTF printing realm but also illustrate the tangible benefits of this versatile printing method. Establishing connections with others in the DTF community through forums and social media can yield invaluable insights and tips, creating a supportive network that fosters learning and shared success. As the DTF printing landscape evolves, these real-life applications showcase the opportunities available for new entrants in the custom apparel market.

Frequently Asked Questions

What is the DTF transfer process in custom apparel printing?

The DTF transfer process involves printing designs onto a special film and then transferring those designs onto garments using a heat press. This method allows for vibrant, detailed prints that are durable on various fabrics. It’s popular among custom apparel businesses for its versatility and ability to cater to different design complexities.

What are the advantages of using DTF printing for custom apparel?

DTF printing offers several advantages, including versatility across multiple fabric types, vibrant color reproduction, durability of prints against washes, and no minimum order requirements. These benefits make DTF printing an excellent choice for personalized projects and small batch production.

Is DTF printing suitable for beginners looking to enter the custom apparel market?

Yes, DTF printing is beginner-friendly due to its lower setup costs and ability to produce small orders without compromising on quality. With the right equipment and design software, even newcomers can create high-quality prints quickly.

What equipment do I need to start DTF printing for custom apparel?

To begin DTF printing, you will need a dedicated DTF printer, high-quality transfer film, and a reliable heat press. Additionally, basic graphic design software is necessary for creating print-ready designs.

Can DTF transfers be applied to all types of fabrics?

DTF transfers are highly versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blends. This flexibility allows for custom apparel creations across many products, from t-shirts to hoodies.

What recent developments are shaping DTF printing technology?

Recent developments in DTF printing technology include improved color management systems for better consistency, eco-friendly inks to appeal to environmentally conscious consumers, and a wealth of online resources for beginners to enhance their skills and knowledge.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on specialized film and applying them to fabrics using heat and pressure. |

| Benefits of DTF Transfers | 1. Versatility: Suitable for various fabrics. 2. Vibrant Colors: Produces bright and detailed prints. 3. Durability: Long-lasting prints that withstand wash and wear. 4. No Minimums: Effective for small orders and personalized projects. |

| Essential Equipment | 1. DTF Printer: Specialized for plastic ink on film. 2. Transfer Film: High-quality film is crucial. 3. Heat Press: Required for transferring designs to garments. |

| Design Software | Programs like Adobe Illustrator and CorelDRAW are necessary for creating print-ready designs, preferably in vector formats. |

| Cost-Effectiveness | DTF printing is typically more affordable for small businesses as it has lower setup costs and no minimum order requirements. |

| Recent Developments | 1. Improved Color Management: Better for consistency. 2. Eco-Friendly Innovations: Sustainable practices are on the rise. 3. Online Resources: Increased support for beginners through communities. |

| Best Practices | 1. Use high-quality artwork. 2. Experiment with different heat press settings. 3. Stay informed with design trends. |

| Case Studies | Entrepreneurs using DTF technology have seen significant sales increases by offering intricate designs previously unattainable with traditional methods. |

Summary

DTF transfers represent a revolutionary shift in the realm of custom apparel printing. By understanding the myriad benefits and requirements of DTF transfers, both beginners and experienced designers can harness this technology to create unique, high-quality garments. The combination of versatility, durability, and cost-effectiveness makes DTF printing an appealing choice for anyone looking to dive into custom printing. With ongoing advancements and a growing community supporting this innovative method, the potential for creativity in apparel design is boundless.