Mastering DTF Transfers opens the door to a new world of creativity and customization within the realm of fabric printing. This innovative DTF transfer technique allows artisans and businesses to achieve remarkable detailing with vibrant colors that stand the test of time. With the right DTF printer setup and knowledge about adhesive powder application, anyone can elevate their custom fabric printing projects to professional levels. In this step-by-step guide, we’ll equip you with essential tips and tools for mastering DTF transfers, ensuring your designs come to life on any material of your choice. Join us as we explore everything you need to know about DTF printing and unleash your artistic potential!

The process of creating stunning fabric designs using Direct-to-Film technology, often referred to as DTF transfers, is rapidly gaining popularity among enthusiasts and professionals alike. This advanced printing method utilizes a specialized film and high-quality inks to produce striking images that can adhere to various textiles. The versatility of the DTF transfer process makes it an ideal choice for custom merchandise and apparel, broadening the horizons for creative expression. By understanding the intricacies of DTF printing, setup, and proper application techniques, you can transform any idea into a tangible masterpiece. Embrace this efficient custom fabric printing solution, and discover the many ways it can enhance your artistic endeavors.

Understanding the Basics of DTF Printing

The world of fabric printing has seen a phenomenal shift with the advent of Direct-to-Film (DTF) printing. This innovative technique allows you to print designs onto a special film, which are later transferred to various fabrics with exceptional clarity and vibrancy. One of the significant advantages of DTF printing is its adaptability; you can use it for cotton, polyester, and even a mix of materials, making it a versatile choice for custom fabric printing. As you delve into the DTF transfer technique, you’ll discover how this method not only produces vivid designs but also offers durability that withstands regular wear and washing.

Moreover, understanding the terminology associated with DTF transfers is essential for anyone looking to master the craft. Familiarize yourself with terminology such as ‘adhesive powder application’ and ‘heat press’ as these are crucial stages in the process. The ability to identify these components will allow you to appreciate the intricate details involved in DTF printing and how each step contributes to the overall quality of the finished product.

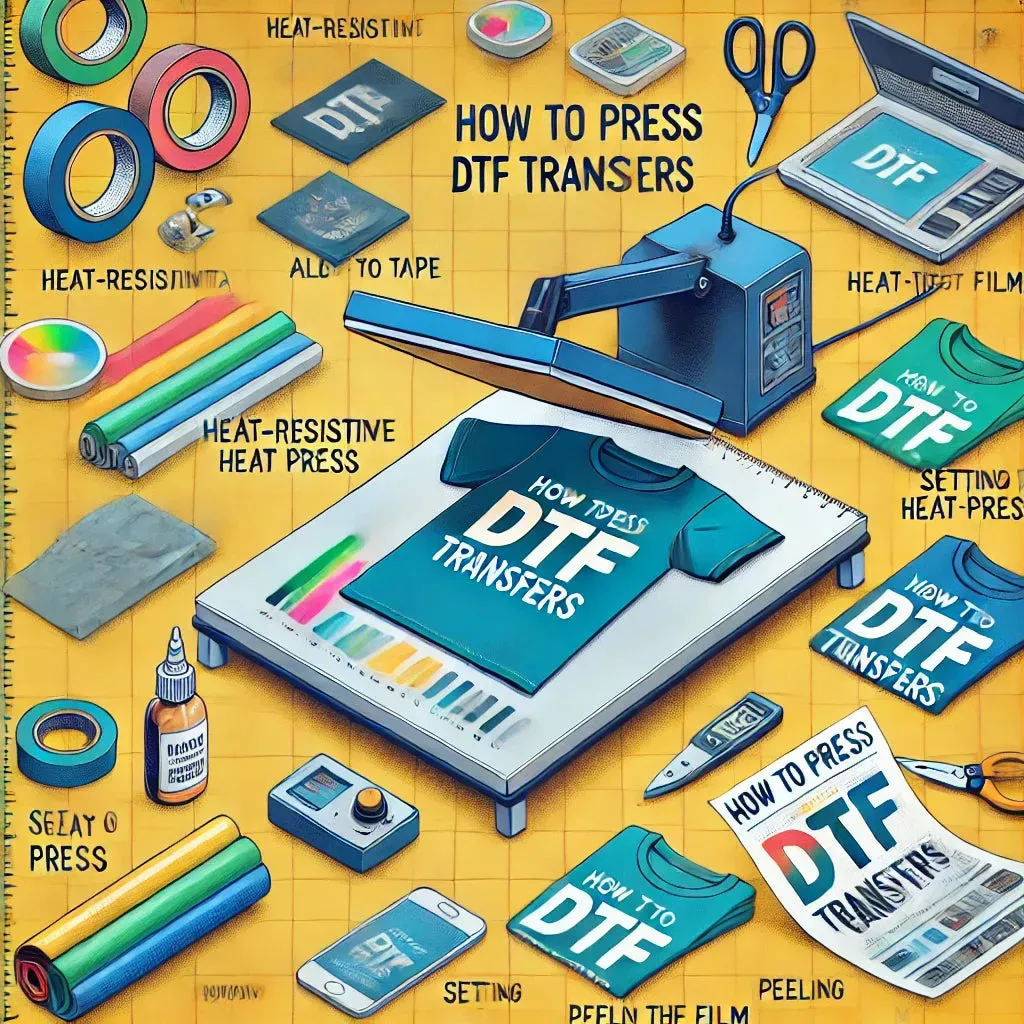

Essential Materials for DTF Transfer Success

When embarking on your DTF transfer journey, having the right materials on hand is paramount. A high-quality DTF printer is essential, as it directly impacts the precision and vibrancy of your prints. Look for models specifically designed for DTF printing that promise reliable performance. Next, you’ll need special DTF film—a crucial component that ensures your ink transfers correctly during the printing process. Combining these materials effectively is key to producing stunning custom fabric prints.

Another essential item in your toolkit is the DTF adhesive powder, which acts as a bonding agent, transferring your design from the film to the fabric. It’s important to handle the adhesive application carefully, as too much can result in a messy print, while too little can weaken the durability of the transfer. Finally, don’t overlook the necessity of a reliable heat press; the right temperature and pressure need to be applied for the duration specified to ensure a successful transfer, solidifying the design onto the fabric.

Step-by-Step Guide to the DTF Process

The process of DTF printing involves several sequential steps that must be executed with precision for success. The journey begins with creating your design using suitable graphic design software, ensuring the dimensions and resolution align with your printing goals. Once your design is finalized, it’s time to initiate the printing process. Load the specially designed DTF film into your printer and print the design, starting with a white layer to provide a solid base for your colors. This foundation layer is key for achieving vibrant color representation on your fabric.

After printing, the next critical step is applying the adhesive powder while the print is still warm, as this aids in the adhesion process. Once the powder is applied, curing it in an oven ensures the adhesive bonds properly to the ink layer, preparing it for transfer. It’s crucial to maintain the right curing temperature to avoid damaging the design. Following this, you’ll transfer the film to your chosen fabric using the heat press, applying specified heat settings and pressure to ensure a perfect bond. Careful peeling of the film reveals a professionally finished product that showcases your design beautifully.

Best Practices for DTF Transfer Techniques

To achieve peak results with DTF transfers, adhering to best practices is essential. Start by optimizing your printer settings, ensuring that you utilize the correct ICC profiles related to your printer and inks. This accuracy in color reproduction can make a substantial difference in the vibrancy and fidelity of your printed designs. Additionally, regularly maintaining your DTF printer will help prevent unwanted print discrepancies that may arise from clogging or improper calibration.

Equally important is configuring your heat press to suit the specific type of fabric you are working with. Different materials often necessitate variations in heat, pressure, and dwell time. Experimenting on test fabric beforehand can help you determine the optimal settings, ensuring the best possible outcome and minimizing the risk of ruining your prints. With meticulous attention to detail and a commitment to continuous improvement, you can elevate your DTF transfer techniques significantly.

Troubleshooting Common DTF Printing Issues

Even seasoned professionals encounter challenges when working with DTF printing. Common issues such as inadequate adhesion or color discrepancies can often be resolved with a keen understanding of the underlying processes. For instance, if you notice that transfers are peeling off after the first wash, it might be due to improper application of the adhesive powder or inadequate curing time. Troubleshooting these problems begins with revisiting your process to identify where adjustments are needed.

Other issues might stem from printer settings or the quality of materials used. For example, using DTF inks that aren’t compatible with your printer can lead to subpar results. Always ensure you are using high-quality DTF inks and conducting regular maintenance on your equipment. Ultimately, fostering a culture of continuous learning and adaptation will help you troubleshoot and fine-tune your approach to DTF transfers successfully.

Exploring Advanced Techniques in DTF Transfers

Once you’ve mastered the basics of DTF transfers, exploring advanced techniques can be both rewarding and creatively fulfilling. Techniques such as layering prints allow you to create complex color schemes, providing depth and richness that standard prints cannot achieve. Additionally, experimenting with textures by mixing different types of fabric or incorporating special inks can set your designs apart and add a unique touch to your custom fabric printing endeavors.

Another exciting realm to venture into is using DTF transfers for promotional purposes. By leveraging these advanced techniques, businesses can create unique promotional items that truly represent their brand. This might include incorporating logos, slogans, or custom artwork that appeal directly to targeted consumers. The ability to innovate in your designs and applications not only showcases your creativity but also positions you prominently in the competitive landscape of custom printing.

Frequently Asked Questions

What equipment is necessary for mastering DTF transfers?

To master DTF transfers, you need essential equipment including a DTF printer, special DTF film, high-quality DTF inks, adhesive powder, a heat press, and graphic design software like Adobe Illustrator. Each of these materials plays a crucial role in the DTF printing process, ensuring vibrant and durable prints.

How does the DTF transfer technique differ from traditional printing methods?

The DTF transfer technique stands out from traditional printing methods by utilizing a unique multi-step process that includes printing on a special film, applying adhesive powder, and using a heat press for transfer. This allows for high-quality, vibrant designs on various fabrics, including cotton and polyester, with greater durability than many other printing techniques.

What is the importance of adhesive powder application in DTF transfers?

The adhesive powder application is crucial in DTF transfers as it creates a bond between the printed design and the fabric. When sprinkled on the printed film, the heat press activates the adhesive, ensuring that the colors transfer seamlessly onto the fabric, resulting in a durable print that withstands washing and wear.

What are the ideal settings for DTF printer setup?

For an optimal DTF printer setup, it is essential to use the correct ICC profiles for your specific printer and DTF inks. Additionally, adjust your printer settings to ensure proper ink flow and vibrant color output. These adjustments will greatly enhance the quality of your final prints in the DTF transfer process.

How can I ensure the best results in custom fabric printing using DTF transfers?

To achieve the best results in custom fabric printing using DTF transfers, ensure you conduct test prints on scrap fabric to determine the ideal heat press settings for your specific material. Also, using high-resolution designs and maintaining proper printer and heat press settings will enhance the vibrancy and longevity of your prints.

What are some common issues faced when mastering DTF transfers, and how can they be resolved?

Common issues in mastering DTF transfers include improper adhesion, fading colors, and peeling designs. To resolve these, ensure proper adhesive powder application, use the correct heat press settings, and test prints on various fabric types. Regularly cleaning your DTF printer and checking ink levels also helps maintain print quality.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A technique where designs are printed on a special film, followed by an adhesive powder application, and finally transferred to fabric using a heat press. |

| Materials Needed | DTF Printer, Special Film, DTF Inks, Adhesive Powder, Heat Press, Design Software. |

| Steps to Mastering DTF Transfers | 1. Create Your Design 2. Printing Process 3. Applying Adhesive Powder 4. Curing the Adhesive 5. Transferring to Fabric 6. Peeling and Finishing |

| Tips for Success | Use correct printer settings, adjust heat press based on fabric, test on scrap fabric first. |

| Additional Resources | ProWorld and The Print Life for tutorials, YouTube channels for visual instructions. |

Summary

Mastering DTF Transfers allows individuals and businesses to delve deep into the art of fabric printing, leveraging advanced techniques that promise vibrant and durable results. This innovative method not only simplifies the process of customizing apparel and merchandise but also opens up new avenues for creativity. With a thorough understanding of the materials, the step-by-step application, and adhering to best practices, anyone can achieve high-quality DTF prints. Stay informed and continuously learn; the realm of DTF technology is ever-evolving, providing countless opportunities to those willing to explore.